User Story IAI Industrial Systems

Personalizing passports and ID cards with printing techniques and laser engravings: this is the specialty of IAI Industrial Systems BV. Machines from the Veldhoven-based company are spread across the globe. This includes the sensors from Panasonic Industry, which provide detailed detection in the machines. But what to do when the delivery of those same sensors is delayed? It required extra effort from all parties involved. Transparency was also necessary, as a foundation for a successful outcome.

The specific features of a passport are not immediately visible. Sure, each passport has its own cover color, featuring the imprint of a national emblem. But the real distinction? It lies in the details, designed for the authenticity of the document. Think of the embossing on the pages, the shadow watermarks, the ink used, and the laser engravings. All these additions make each passport issue a unique product, says Frank van Lierop. “The production of a passport has numerous parameters. About 60 percent is always the same, while the remaining part is customer-specific.”

Customization, therefore. And hence the differences between the machines of IAI, where Frank is a technical buyer. They do not produce the blank, unprocessed passport booklets here; that is the job of another specialist. But the methods to personalize the booklets and equip them with security features? That is the specialty here in Veldhoven. From development, engineering, and assembly to customer acceptance: it all comes together in special machines for customers worldwide. These, Frank explains, can count on the support of IAI service technicians and an extensive network of partners. “We have mapped everything for our customers, whether it’s about preventive maintenance or spare parts.”

Wanted: The Latest Technology

IAI operates in a niche market, served globally by a handful of companies. If they don’t keep each other sharp, it’s the changing customer demand, according to Frank. “A passport is typically replaced every seven to ten years, with customers expecting new applications each time. We adapt to this and strive to stay ahead with the latest developments.”

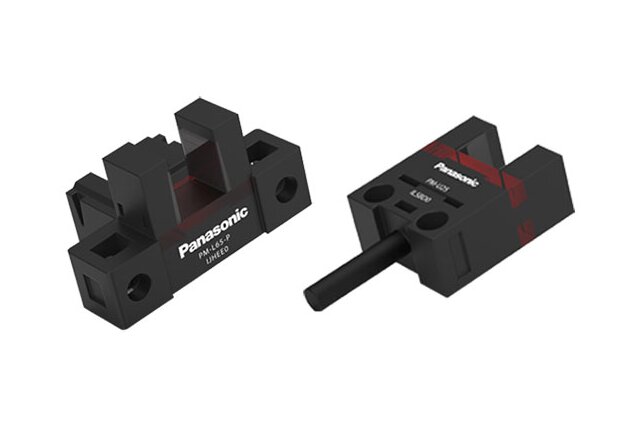

To achieve this, IAI collaborates with suppliers AAE, MTA, and Mevi. All three are based in Helmond and each take responsibility for a complete part of an IAI machine as strategic partners. This comes with the necessary specifications, although some components are common across every module. This includes the fork sensors from Panasonic Industry, which provide the necessary detection in multiple positions within the machines. “Each of our machines includes about twenty to thirty Panasonic sensors,” Frank explains. “They work well; our engineers have consciously chosen them. We can’t do without them.”

What If the Delivery Stalls?

This highlights the importance of timely delivery of the sensors, which for IAI happens through the technical service provider itsme. For a long time, this process went smoothly, almost as a matter of course. Until the challenges in the global supply chain began to have an impact here as well. In the summer of 2022, the sensors were no longer available, jeopardizing the timely delivery of already ordered machines. “So I contacted Panasonic directly,” Frank recounts, “and the company took significant action.”

It was Marcel Harks, distribution account manager at Panasonic Industry, who initiated weekly meetings with IAI and itsme, keeping all parties informed. The team from Panasonic Industry in Best also contributed ideas regarding the application of other, available sensors. This was to the satisfaction of Frank and his colleagues. “Some adjustments were indeed necessary in the machine, including on a mechanical level. But we worked well together with Panasonic on that.”

Quick and Complete Coordination

Coincidentally, Panasonic System Solutions in Japan was one of the customers for multiple IAI machines. However, this was not the reason for the timely delivery of the sensors to IAI, Marcel explains on behalf of Panasonic Industry. “Because that drive is always there, for every customer. It simply comes down to quick and complete coordination. And that has certainly been done recently by our European supply team, which has kept close contact with our Japanese production site. In that respect, we achieved a company-wide result with the delivery of our sensors.”

The situation regarding the sensors is no longer as pressing as it was in the summer of 2022, which means the collaboration is becoming less intensive, Frank knows. “But looking back now, I am still pleasantly surprised. I only knew Panasonic from the sensors via Itsme before, but I have now experienced the company in a different way. That such a large corporation goes to such lengths for us says a lot. The discussions with Marcel, the transparency, and the deliveries: we have been well supported on multiple fronts.”

Certainly, a faltering supply chain is challenging, Frank notes. “Yet such a situation also makes you creative. Where you would otherwise postpone things, you are now forced to deviate from the beaten path. That requires extra effort from all parties, but it is precisely then that much is possible. I think we have proven that with our collaboration.”

Specialist in Document Security

IAI Industrial Systems BV has been around for over thirty years. Initially focused on more general machine construction, the company later shifted its focus to document security with expertise in optical and laser applications. The vast majority of IAI's special machines are intended for the personalization of passports. The company also manufactures machines for the personalization of ID cards, as well as specials for birth certificates or banknotes. Since 2015, IAI has been part of the security concern Assa Abloy.