Methods

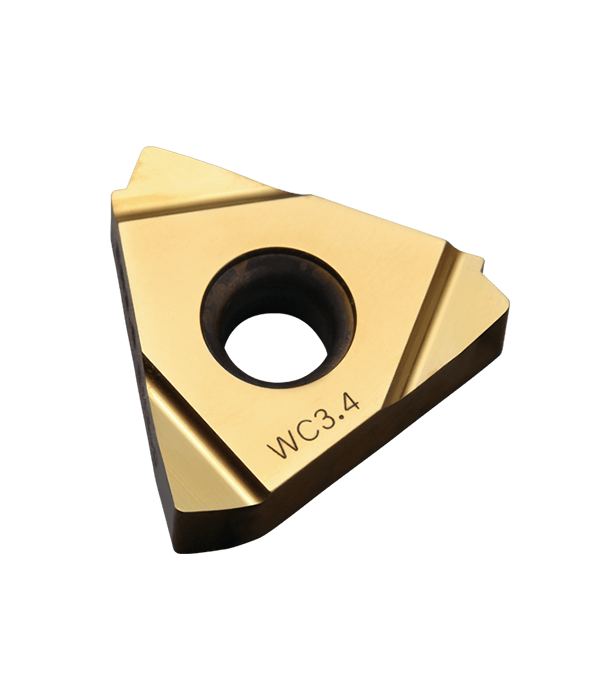

Engraving

This marking method removes layers of material and makes depressions in the surface. Due to the very high power density of the laser radiation, local vaporization or melt expulsion occurs. Even very hard metallic materials or ceramics can be marked permanently with this marking method. The depression depth can be controlled via processing parameters. Engravings are not subject to wear and tear.

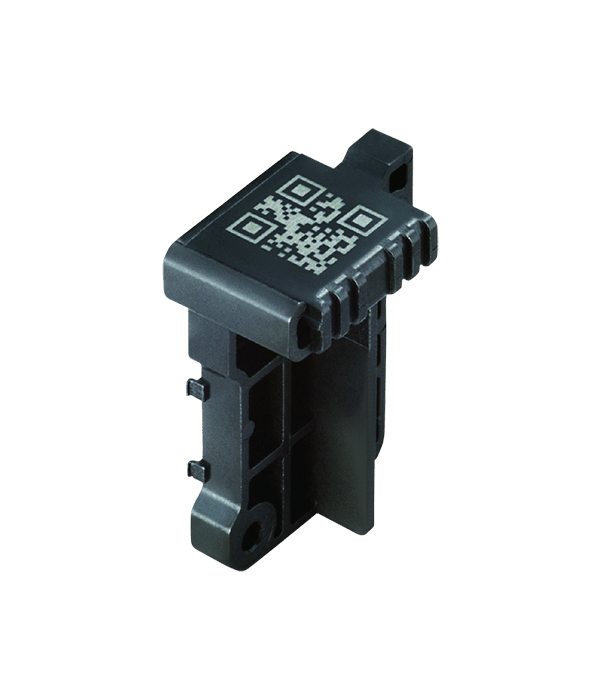

Appropriate technology:

Annealing

Metals like stainless steels or titanium are locally heated by the laser, which results in changes to the microstructure and the creation of an oxide layer. These two factors generate a colored marking. Depending on the temperature and thickness of the oxide layer, this method creates different colors like yellow, green, red, blue and even black. Black marking achieves the highest contrast, is not subject to wear and tear, and the surface remains absolutely smooth since no material is removed.

Appropriate technology:

Foaming

The marking method of foaming is only possible with certain synthetic materials. The laser beam locally melts the synthetic material and due to the vaporization of the carbons and additives, small gas bubbles are formed which foam up the synthetic material. The cooling rate is sufficiently high to firmly enclose the bubbles. This way, a raised marking is produced. The incident light is diffusely reflected in this "foam" and the marking appears bright and with high contrasts on dark resins.

Appropriate technology:

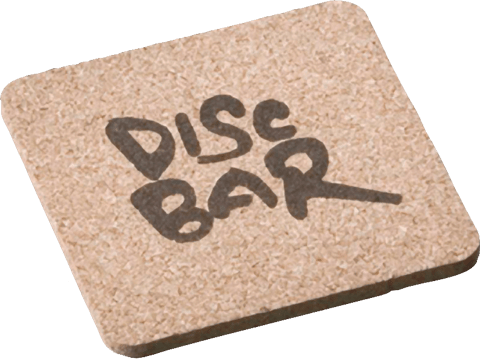

Carbonizing

Carbonization is a thermochemical reaction that breaks up carbon compounds to release carbon. Carbonization is used for bright resins and organic materials (paper, cardboard, wood and leather) where the color effect to be achieved is from bright to dark.

Appropriate technology:

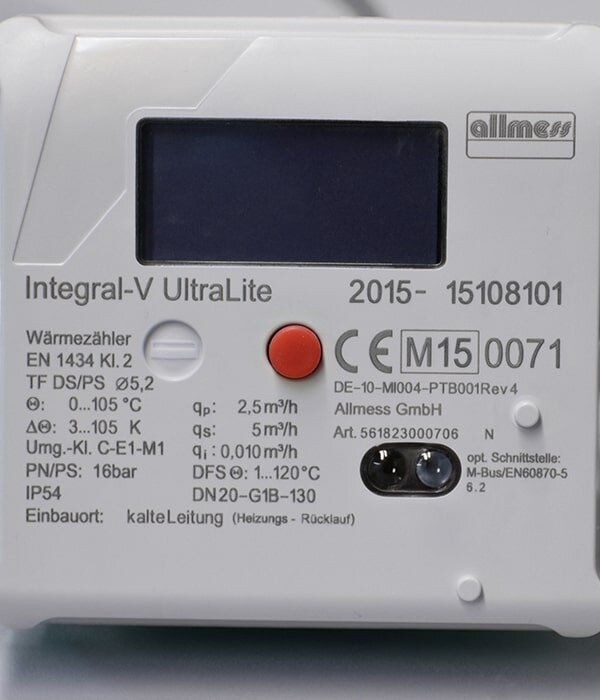

Layer removal

This marking method acts as an indirect marking of coated materials, i. e. anodized aluminium, laser marking films, and painted base materials. The laser beam removes the already applied covering layers by vaporization and the base materials become visible again, which leads to the marking effect. This marking method is frequently used in applications of the automotive industry to produce a day/night design of dashboards.

Appropriate technology:

Do you want to mark your products with a laser?

If yes, please send us some samples and we will show you the best-quality laser marking for your product and application. We are happy top advise you when you send us your requirements together with some samples - simply fill in the request form and let us convince you of the quality of Panasonic's laser marking.

Fill in the request form and send it together with your samples to:

Panasonic Industry Europe GmbH

Laser Marking and Processing Laboratory

Maria-Merian-Strasse 7

85521 Ottobrunn

Germany