Ultra-light EMC shielding material

Overview

- Ultra- light EMC shielding material with a bulk density of 0.01g/cm³ using carbon nanotubes.

- This materials can be tuned to adjust the shielding performance in accordance with device frequencies.

- Excellent workability enables the creation of 3D structures.

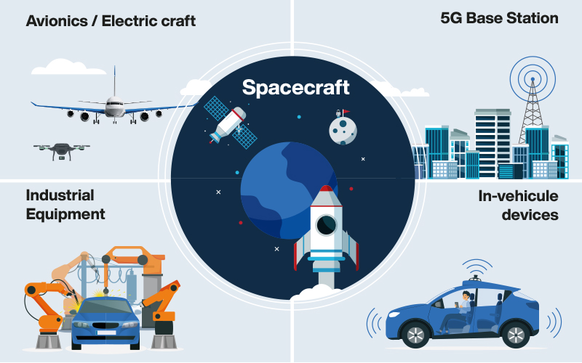

Application

- Aerospace

- Wireless

Detailed use:

Spacecraft (artificial satellites, space probes, etc.), Electric aircraft (drones, eVTOL vehicles, etc.), 5G/6G application-related devices (mobile base stations, etc.), Industrial equipment (robots, AGVs, etc.), In-vehicle devices (millimeter wave radar, various sensors, etc.), VR/AR devices, etc.

Concept

By combining our thermosetting polymer formulation compounding design technology based on carbon nanotubes with environmental test technology and know-how assuming various use cases, we have achieved both lightness and excellent electromagnetic shielding and absorption. Ultra-light EMC shielding material contributes to weight reduction of equipment and improvement of communication quality.

* To be studied about control methods in joint research project on "Ultra-light EMC shielding material" technology, under JAXA's "Solution Creating Research" for space exploration. Research period: June 2022 to June 2024

Joint research members:

- JAXA: Japan Aerospace Exploration Agency

- Nagoya University

- Yamagata University

- Akita University

- Tohoku University

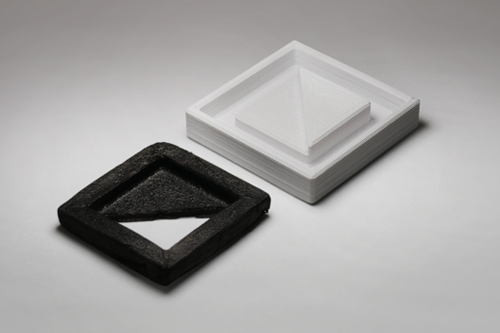

3D structure molding

Three-dimensional structures can be created using Panasonic Industry's thermosetting resin formulation technology and freeze-drying manufacturing method, enabling processing customized to the shape of the devices made with these new materials.