Multilayer NTC thermistors

Features

Panasonic NTC Thermistors have the following features at the top level of the industry.

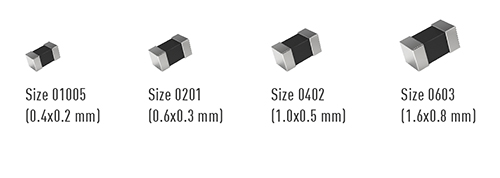

- A wide range of temperature coefficients and resistance values are available in the surface mount type (01005, 0201, 0402, 0603 size).

- Achieved high reliability with a laminated structure and unique external electrode formation technology.

- Wide lineup of resistance temp. coefficient (B value) and resistance values.

- Highly reliable multilayer / monolithic structure / unique electrode design (Operating temperature range: –40 to 125°C).

- Automotive grade line-up with high heat resistance (usage up to 150°C)

What are NTC thermistors?

NTC thermistors is a ceramic component and it changes its resistance value as the ambient temperature changes.

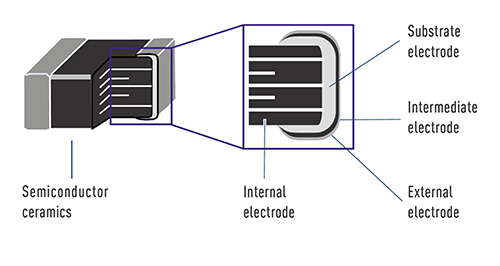

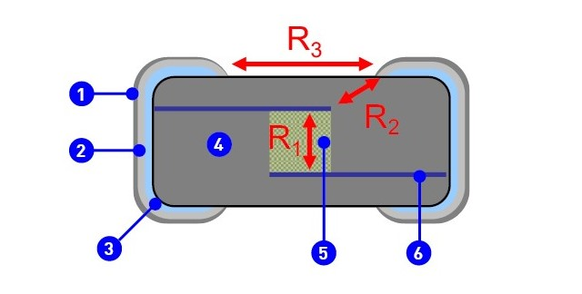

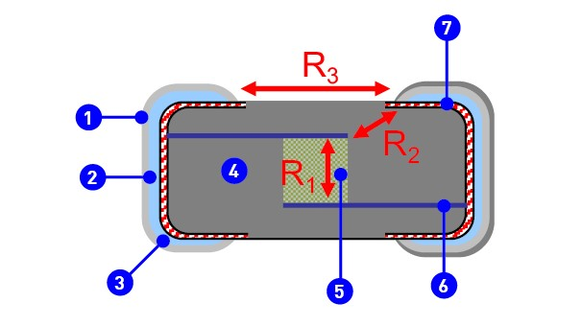

Construction

The multilayered structure enables to design various resistance values.

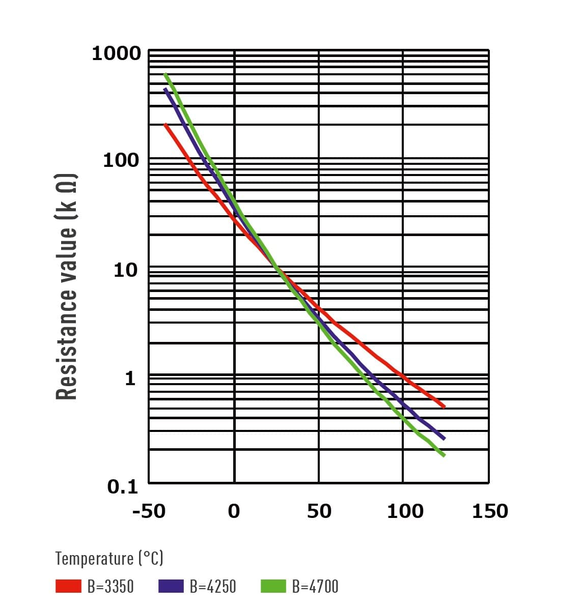

Temperature characteristics

As the temperature increases, the resistance value decreases.

The bigger the B-value, the resistance value changes become large.

Element Technology

Realized high-reliability by creating a high-insulation layer, using our electrode forming technique!

Conventional technology

- External electrode

- Intermediate electrode

- Substrate electrode

- Semiconductive Ceramics

- Active area

- Internal electrode

Due to not having a high-resistance layer, it is easily affected by external factors: reflow soldering, surrounding environment and atmosphere.

Panasonic technology

- External electrode

- Intermediate electrode

- Substrate electrode

- Semiconductive Ceramics

- Active area

- Internal electrode

- High resistance layer

The internal electrodes are protected by a high-resistance layer, so it’s not easily affected by external factors: reflow soldering, surrounding environment and atmosphere.

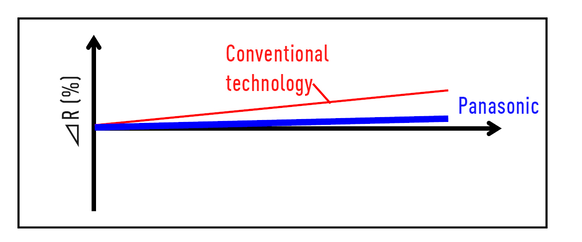

Change in resistance value

Image of change in resistance value through the reflow soldering and reliability test.

Panasonic Thermistors maintain temperature control in high precision for a long period.

Basic reliability tests

| Items | Testing methods | Evaluation items | Automotive | General | |

|---|---|---|---|---|---|

| High precision | Standard | ||||

| Shock resistance | Shock waveform: Semisinusoidal wave 11ms Impact acceleration: 50G Impact direction: X-X’ ,Y-Y’, Z-Z’(3 times for each direction) |

Change rate of Resistance | Within ±2% | - | - |

| Change rate of B-value | Within ±1% | - | - | ||

| Temperature cycle | -40 (Automotive: -55) ±3°C (30±3min)

The operation prescribed above is one cycle, and repeat it for 100 times |

Change rate of Resistance | Within ±2% | Within ±2% | Within ±3% |

| Change rate of B-value | Within ±1% | Within ±1% | Within ±2% | ||

| Moisture resistance | Testing temperature: 85±2°C Relative humidity: 85±5% Testing time: 1000+48/0 hours (Automotive: 2000+48/0 hours) |

Change rate of Resistance | Within ±2% | Within ±3% | Within ±3% |

| Change rate of B-value | Within ±1% | Within ±1% | Within ±2% | ||

| Damp heat load | Testing temperature: 85±2°C Relative humidity: 85±5% Power applying: 10mW Testing time: 1000+48/0 hours (Automotive: 2000+48/0 hours) |

Change rate of Resistance | Within ±2% | Within ±2% | Within ±3% |

| Change rate of B-value | Within ±1% | Within ±1% | Within ±2% | ||

| Low temperature storage | Testing temperature: -40±3°C Testing time: 1000+48/0 hours (Automotive: 2000+48/0 hours) |

Change rate of Resistance | Within ±2% | Within ±2% | Within ±3% |

| Change rate of B-value | Within ±1% | Within ±1% | Within ±2% | ||

| High temperature storage #1 | Testing temperature: 85±3°C Testing time: 1000+48/0 hours |

Change rate of Resistance | - | Within ±2% | - |

| Change rate of B-value | - | Within ±1% | - | ||

| High temperature storage #2 | Testing temperature: 125±3°C (Automotive: 2000+48/0 hours) |

Change rate of Resistance | Within ±2% | Within ±2% | Within ±3% |

| Change rate of B-value | Within ±1% | Within ±1% | Within ±2% | ||

| High temperature storage #3 | Testing temperature: 150±3°C Testing time: 1000+48/0 hours |

Change rate of Resistance | Within ±3% | - | - |

| Change rate of B-value | Within ±2% | - | - | ||

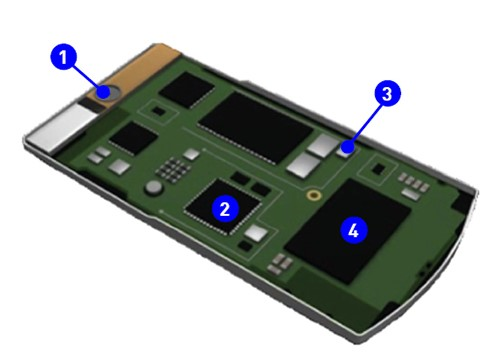

Example of multilayer thermistors usage - Smartphones

1. Heating detection of LED for camera module

Consecutive light emission by photographing still images and moving images causes temperature rising.

We recommend ultracompact type to incorporate Thermistors module.

- Ultracompact (01005) type

- Recommended P/N: ERTJAEG104F

2. Temperature detection of CPU

To control the heat of high-speed CPU

- Compact type (0201)

- Ultracompact type (01005)

- Recommended P/Ns:

- ERTJZEG103FA

- ERTJAEG103FA

3. Temperature detection of quarts oscillator

It detects the temperature change and corrects the oscillating frequency, which are highly accurate.

- Type 0201

- Recommended P/N: ERTJZER104F

4. Temperature detection of battery pack

Compact and high-accuracy type

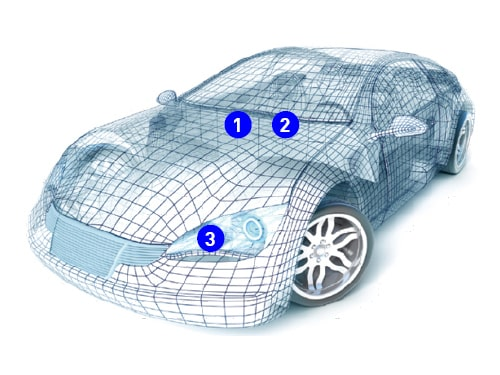

Example of multilayer thermistors usage - Automotive equipment (ECU)

We provide you automotive grade components that have high heat resistance (150°C), high accuracy and high reliability.

1. Car navigation

- Temperature detection for power amplifier and LCD

2. Air conditioner

- To detect the interior temperature

3. LED light

- To detect temperature of LED lights

Thermistors enable automotive devices to miniaturize, lighten, detect temperature in high accuracy and reduce the cost.

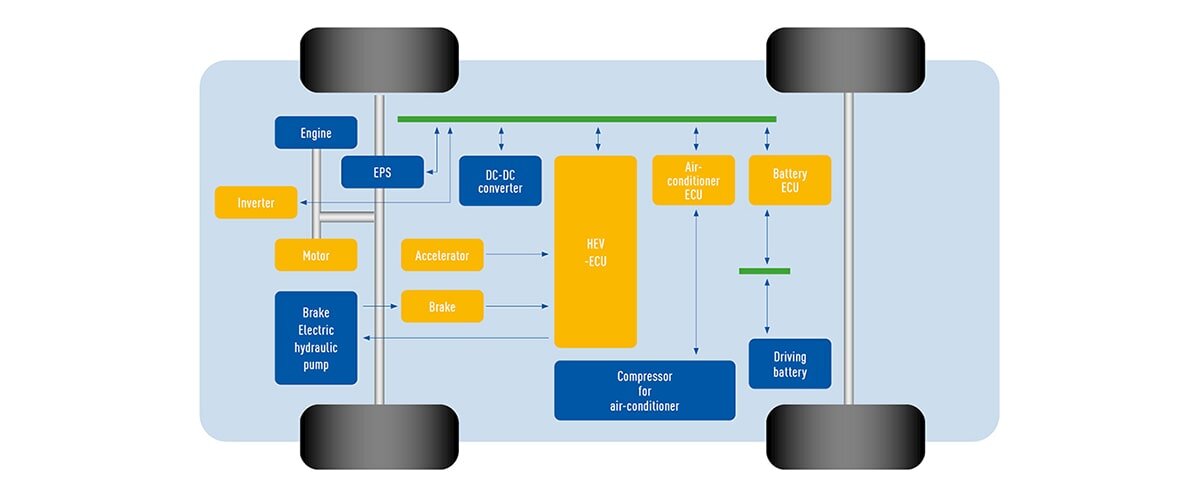

Example of multilayer thermistors usage - Automotive equipment (HEV, PHEV, EV)

HEV/PHEV/EV related

- BMS (Battery Management System)

- Electric compressor

- Electric pump

- IPM (Intelligent Power Module)

- DCDC converter

- Regeneration brake