Motion Controller GM1

Motion Controller GM1 for complex motion control applications

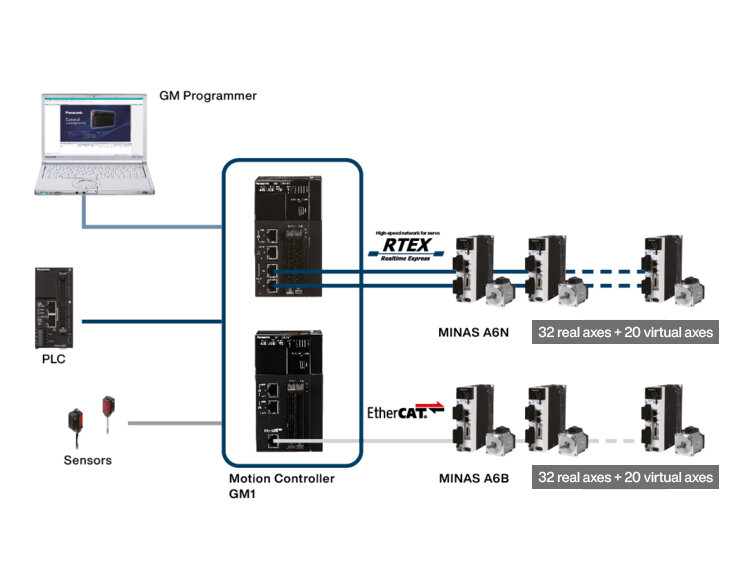

With the space-saving Motion Controller from Panasonic Industry you can master your challenges with your multi-axes machines: The GM1 offers control of up to 52 axes (32 real and 20 virtual axes), standardized communication via EtherCAT, easy network integration via EtherNet/IP, and sophisticated programming with CODESYS.

All these features make the Motion Controller the ideal choice for use in machines with challenging motion profiles such as rotary knives, path interpolation or synchronization and coupling of axes.

The GM1 is a combination of several units (a positioning unit, a network unit, an I/O unit, and a high-speed counter unit) which in conventional solutions have to be installed separately.

Overview of the most important functions and features

Configuration software with

- User assistance for choosing the right function blocks

- Smooth editing of cam curves

- Simulation and debug function

Synchronous control

- Complex multi-axis systems like systems with 2- and 3-axis interpolation

High-speed response

- For fast data exchange and networking

Programming with CODESYS

- Standard programming languages according to international standard IEC 61131

| Motion control | Ethernet protocols | RS232C | Selectable network |

|---|---|---|---|

|

|

|

|

| General-purpose I/O | High-speed counter input | High-speed response | PWM output |

|

|

|

|

System configuration

Applications

The GM1 is specially designed for motion control solutions, where high precision like interpolation control and a sensitive response are needed. Therefore, the space-saving Motion Controller offers high-speed and high accuracy for applications like printing, packaging, press-fitting, or molding. Compared to conventional PLCs, the GM1 is ideally suited for motion applications like a rotary knife, flying shear, labeling, palletizer, crank, cam synchronization, or print mark evaluation (position control).

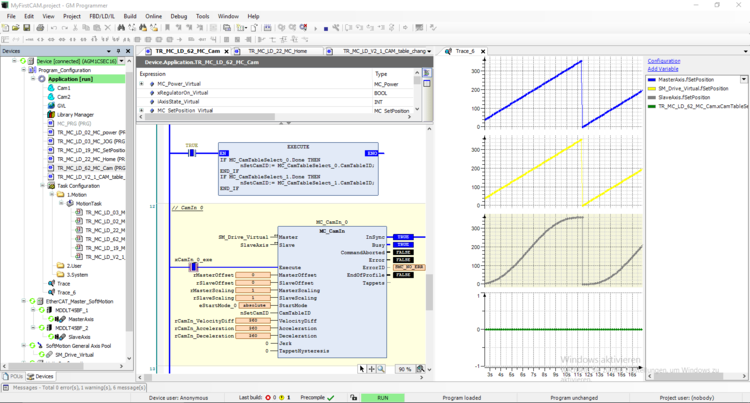

Configuration software - GM Programmer

GM Programmer is the associated software for setting the GM1 controller, editing, and downloading programs. It complies with the IEC 61131-3 standard.

Users can choose between 6 different programming editors to configure their system. Settings can be tested before implementation with the offline simulation function.

6 programming languages

- LD (Ladder Diagram)

- FBD (Function Block Diagram)

- ST (Structured Text)

- SFC (Sequential Function Chart)

- CFC (Continuous Function Chart)

- IL (Instruction List)

Easy programming with the help of the pre-installed standard library with function blocks for motion control. When you select a function block, the “Function Block Guidance” feature shows details about the function block parameters.

Debugging is made easier by offline simulation and features such as motor tracing, timing adjustment and other functions. This helps to reduce the time and effort needed for designing the system.

The intuitive graphical user interface allows you to configure the cam curves easily.

Controller

| Number of axes | Network | Number of I/O | High-speed counter | Rated voltage | Output specifications | Part No. |

|---|---|---|---|---|---|---|

| 32 axes | RTEX |

16 inputs 16 outputs |

2 ch | 24V DC | Transistor output (NPN) | AGM1CSRX16T |

| 32 axes | EtherCAT |

16 inputs 16 outputs |

2 ch | 24V DC | Transistor output (PNP) | AGM1CSEC16P |

Input / output unit

| Type | Number of I/O | Specifications | Part No. |

|---|---|---|---|

| DC input | 64 inputs | 24V DC, 32 inputs / 1 common | AGM1X64D2 |

| Transistor output (PNP) | 64 outputs | Maximum load current: 0.3A (20.4 to 26.4V DC), 30mA (4.75V DC); 3.2A / common, 32 outputs / 1 common | AGM1Y64P |

| DC input / Transistor output (PNP) |

32 inputs 32 outputs |

Input: 24V DC, 32 inputs / 1 common Output: Maximum load current: 0.3A (20.4 to 26.4V DC), 30mA (4.75V DC); 3.2A / common, 32 outputs / 1 common |

AGM1XY64D2P |

Analog input / output unit

| Product name | Specifications | Number of channels | Part No. |

|---|---|---|---|

| Analog input unit |

Conversion speed 50μs / 8 ch Resolution 16bit (maximum) Accuracy max. ±0.2% F.S. (at +25°C) |

8 ch | AGM1AD8 |

| Analog output unit |

Conversion speed 50μs / 4 ch Resolution 16 bit (maximum) Accuracy max. ±0.2% F.S. (at +25°C) |

4 ch | AGM1DA4 |

Pulse output unit

| Output type | Number of control axes | Speed command | Part No. |

|---|---|---|---|

| Transistor | 4 axes | Max. 500kpps | AGM1PG04T |

| Line driver | 4 axes | Max. 4Mpps | AGM1PG04L |

Serial communication unit

| Specifications | Part No. |

|---|---|

| 2 x RS232C | AGM1NSCS2 |

| 2 x RS422A / RS485 | AGM1NSCM2 |

| 1 x RS232C 1 x RS422A / RS485 |

AGM1NSCS1M1 |

Accessories

| Product name | Part No. |

|---|---|

| Discrete-wire connector set | AFP2801 |

| Flat cable connector set | AFP2802 |

| Spring force plug set | AFP2808 |

| Power cable | AFPG805 |

Downloads

| Name | Size | Date | Language |

|---|---|---|---|

| GM1 series, CAD data, step | 2 MB | 28.06.2022 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Motion Controller GM1 Series, catalog, 4255euen | 2 MB | 01.09.2022 | English |

| Controlador de movimiento Serie GM1, 4255eues | 6 MB | 01.09.2022 | Spanish |

| Motion Controller GM1 Serie, Katalog, 4255eude | 2 MB | 24.05.2022 | Deutsch |

| Collaboration Catalog – Network, Linear and Direct Drive Motor Control System 2023-02 | 19 MB | 22.02.2023 | English |

| Contrôleur de mouvements multiaxes Série GM1 , 4255eufr | 2 MB | 24.05.2022 | French |

| Motion Controller GM1 Series, catalog, 2025-05 | 11 MB | 23.05.2025 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| GM1 Motion Controller, flyer, 4254euen | 2 MB | 20.02.2024 | English |

| Controlador de movimiento GM1, flyer, 4254eues | 2 MB | 20.02.2024 | Spanish |

| Name | Size | Date | Language |

|---|---|---|---|

| GM1 Controller RTEX User’s Manual (Operation), WUME-GM1RTXOP-09 | 41 MB | 24.05.2024 | English |

| GM1 Controller RTEX User’s Manual (Setup), WUME-GM1RTXSU-05 | 4 MB | 10.11.2023 | English |

| GM1 Series Reference Manual (Instruction Edition), WUME-GM1PGR-11 (2025.12) | 26 MB | 14.01.2026 | English |

| GM1 Series Reference Manual (Hardware), WUME-GM1H-11 (2025.12) | 6 MB | 14.01.2026 | English |

| GM1 Controller EtherCAT User’s Manual (Setup), WUME-GM1ETCSU-03 | 5 MB | 10.11.2023 | English |

| GM1 Series Reference Manual (Pulse Output Unit), WUME-GM1PG-06 | 4 MB | 23.06.2025 | English |

| GM1 Series Reference Manual (Analog I/O Unit Edition), WUME-GM1AIO-06 | 1 MB | 27.11.2024 | English |

| GM1 Controller EtherCAT User’s Manual (Operation), WUME-GM1ETCOP-08 | 43 MB | 24.05.2024 | English |

| GM1 Controller User’s Manual, WUME-GM1OP-02 | 37 MB | 23.06.2025 | English |

| GM1 Controller Serial Communication Reference Manual, WUME-GM1SC-02 | 928 KB | 23.06.2025 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Bundle solution for motion application, Short overview 2023: Servo drives - Motion controller PLC - HMI - Communication, 4256euen | 2 MB | 05.04.2023 | English |

| Top seller - Automation products, 6215euen | 3 MB | 01.05.2024 | English |

| Übersicht Topseller Automatisierungstechnik, 6215eude | 3 MB | 02.05.2024 | German |

| Les essentiels - Produits d’automatisme, 6215eufr | 5 MB | 16.06.2023 | French |

| Overview Programmable Logic Controllers, 4104euen | 4 MB | 01.05.2024 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| GM Programmer V2.0.1.0: Programming software for motion controller GM1. Incl.GM1 Firmware update 2.0.0.0. Works with Windows 10/11. | 2 GB | 20.01.2026 | English |

| GM1 Motion Controller EtherCAT type, EDS file | 2 KB | 23.03.2022 | English |

| GM1 Motion Controller RTEX type, EDS file | 2 KB | 23.03.2022 | English |