LP-ZV Series

Fiber Laser Marking Systems LP-ZV Series

3D short-pulse fiber laser marker

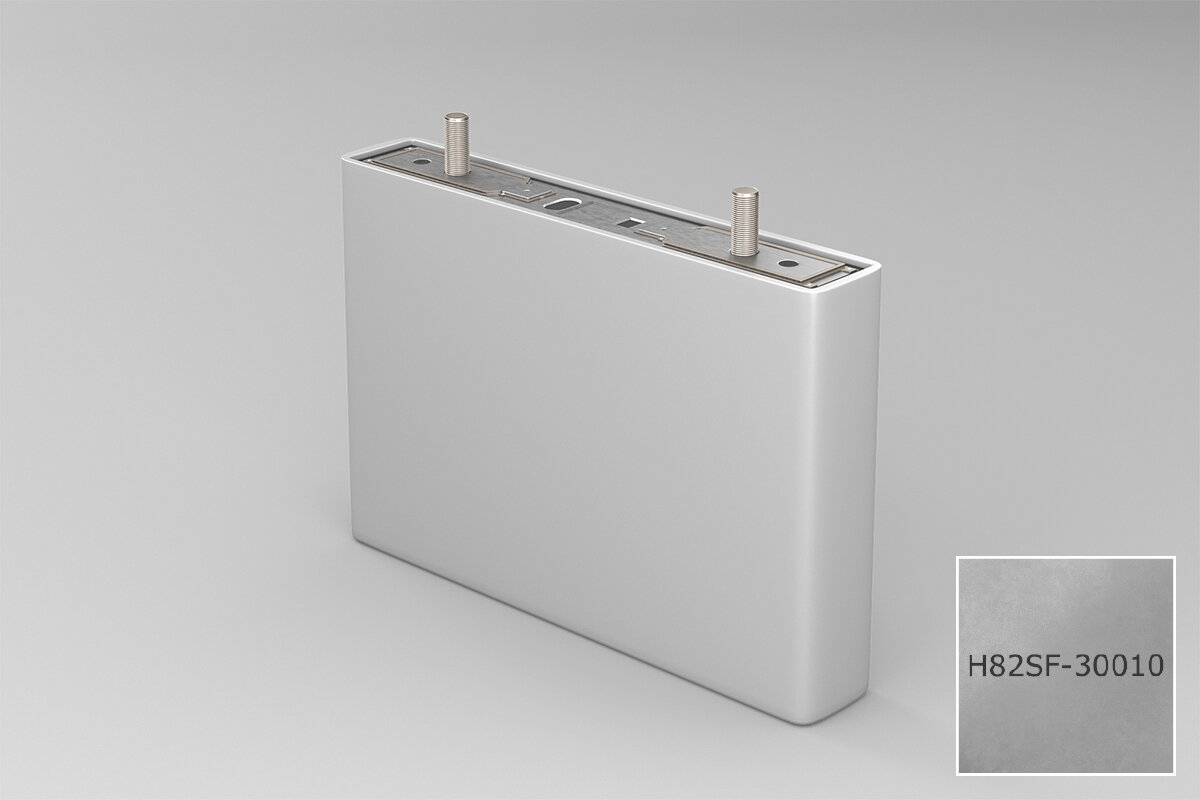

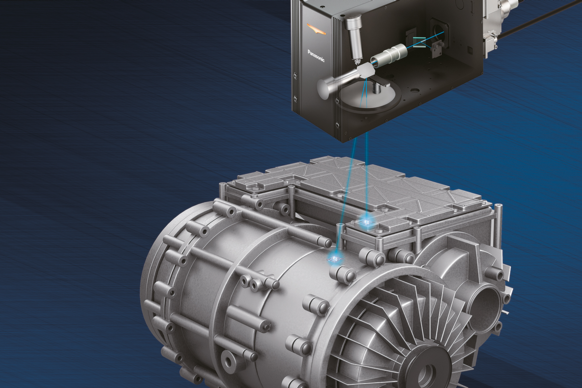

Panasonic Industry's long-lasting, energy-efficient fiber laser markers have further evolved to a laser marking system with 1ns short pulses and 3D control. With a built-in camera, our 3D fiber laser markers contribute to higher productivity.

3D Fiber Laser with built-in camera for positioning

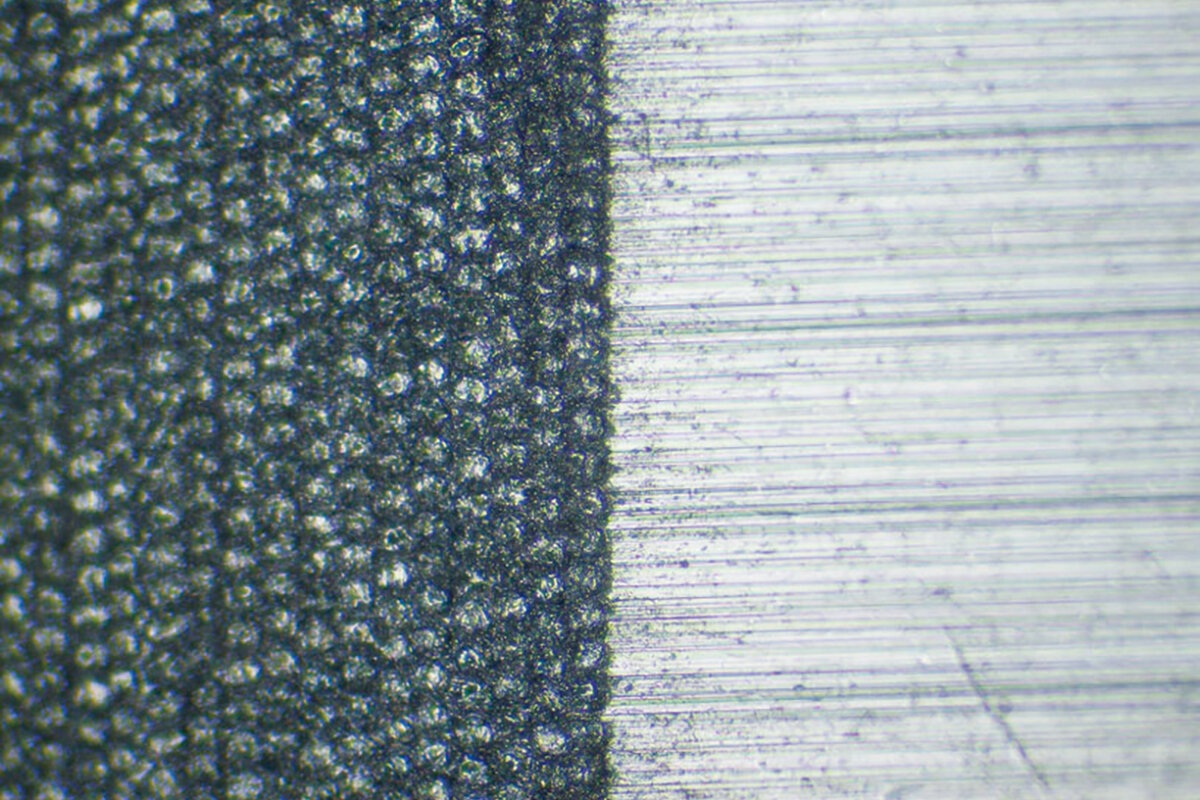

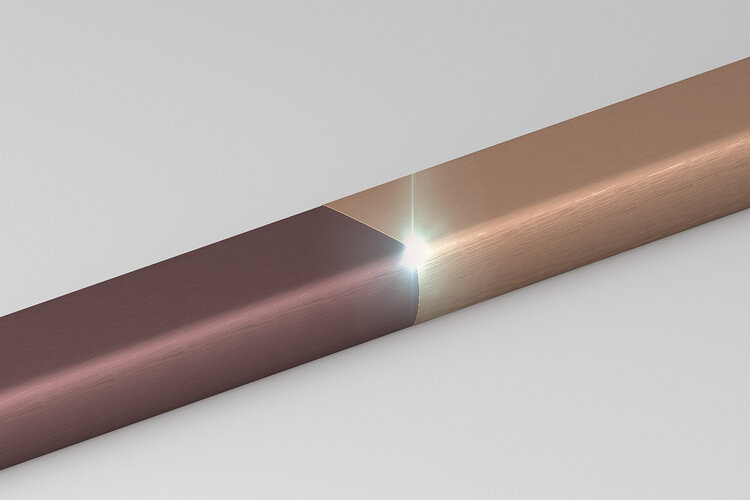

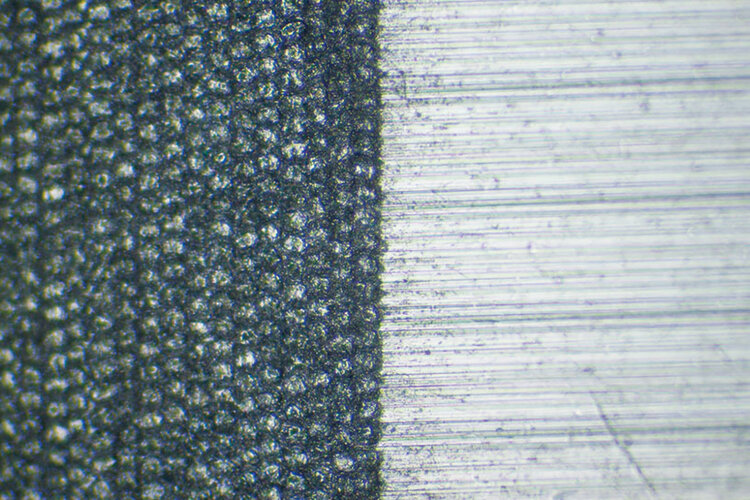

Panasonic Industry's long-lasting, energy-efficient fiber laser markers have further evolved to a laser system with 1ns short pulses and 3D control. Thanks to the high output power (50W), the new fiber laser markers offer excellent metal marking quality combined with high contrast marking and extra small character marking on resin. With a built-in camera, our 3D fiber laser markers contribute to higher productivity.

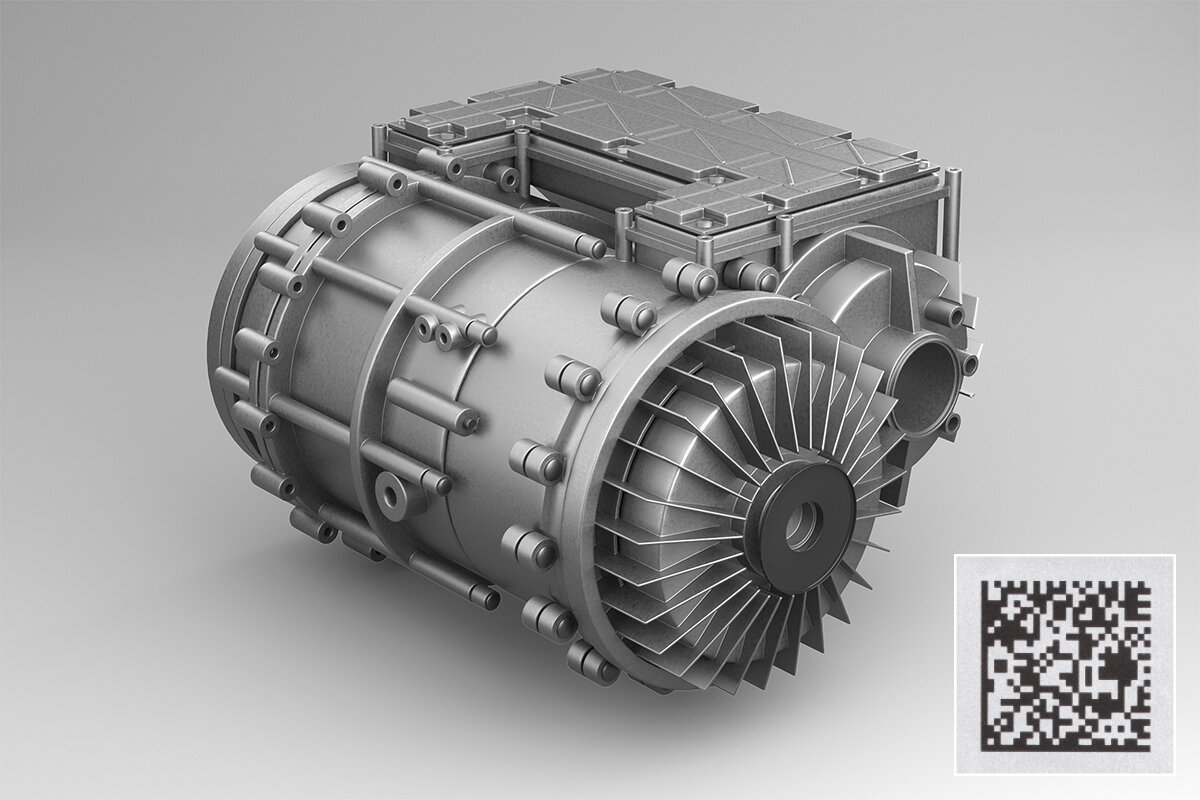

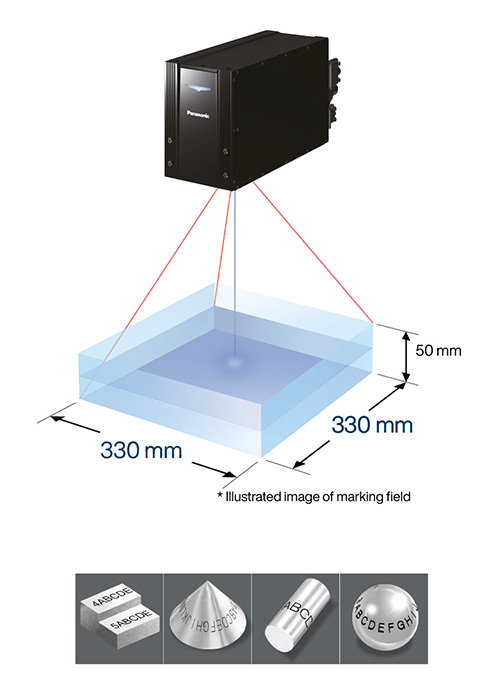

Wide marking field of 330mm × 330mm

Positioning can be performed by viewing the marking data and the workpiece image captured by the built-in camera on the same display. Compared to the conventional red guide, the color image makes it easier to check the positioning. In addition, the internal light in the head enables positioning even in dark places such as inside a machine.

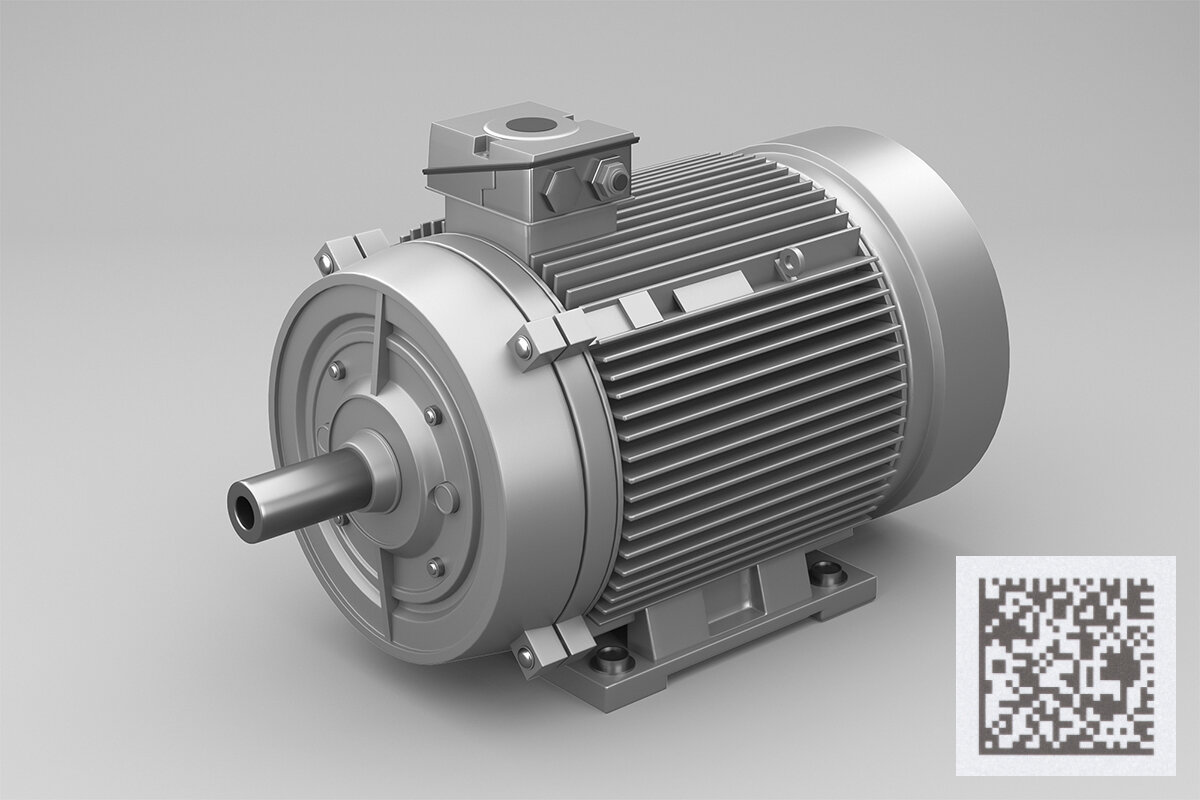

Conventionally, markings on large workpieces or on workpieces made with multi-cavity molds required multiple marking operations. The wide marking field enables large size marking in a single marking operation. This not only improves productivity, but also reduces the number of required units or simplifies the facility construction to contribute to cost reduction.

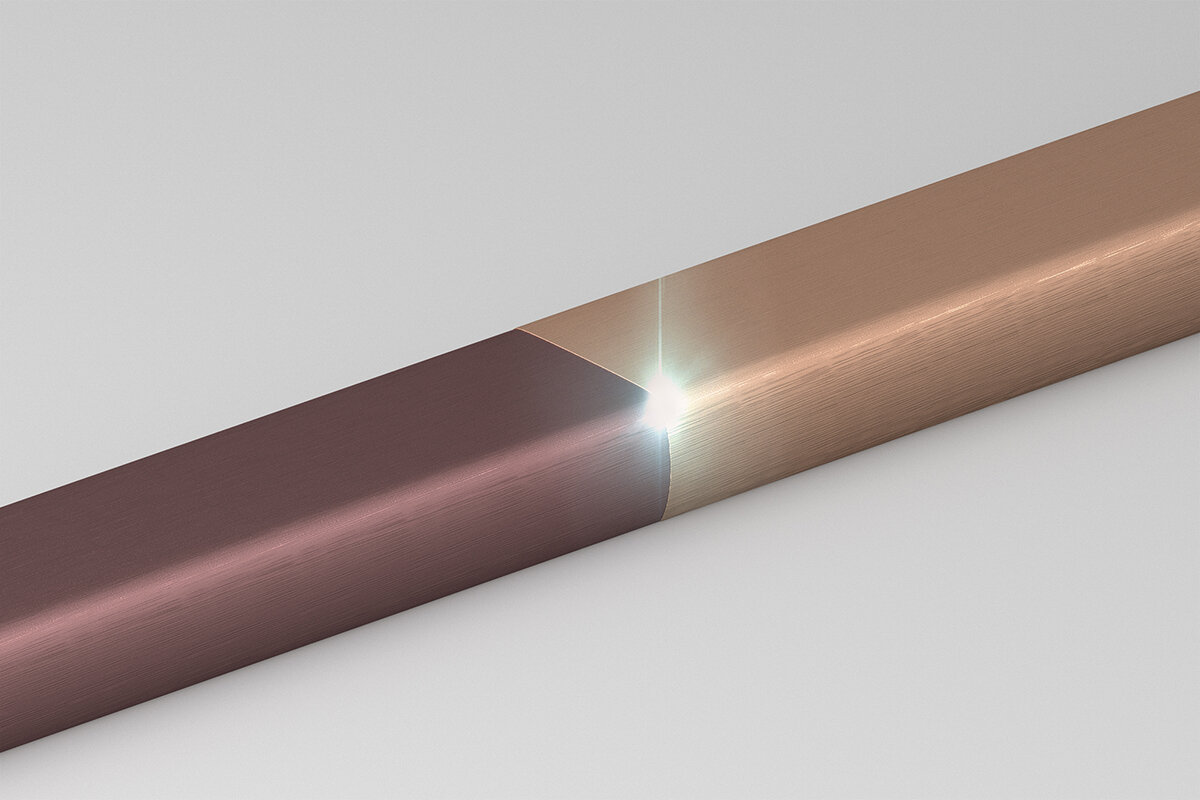

Z-axis control in an area of 50mm (±25mm)

The Z-axis control allows for the marking of oblique, convex and concave surfaces in an area of 50mm (±25mm). Even workpieces with different heights can be marked easily with this new technology. Inside the marking field the spot size remains stable, ensuring consistent, high-quality marking. The wide range also eliminates the need for a setup change when workpieces with different heights are sent on the same line. This feature can dramatically reduce setup, installation and design costs.

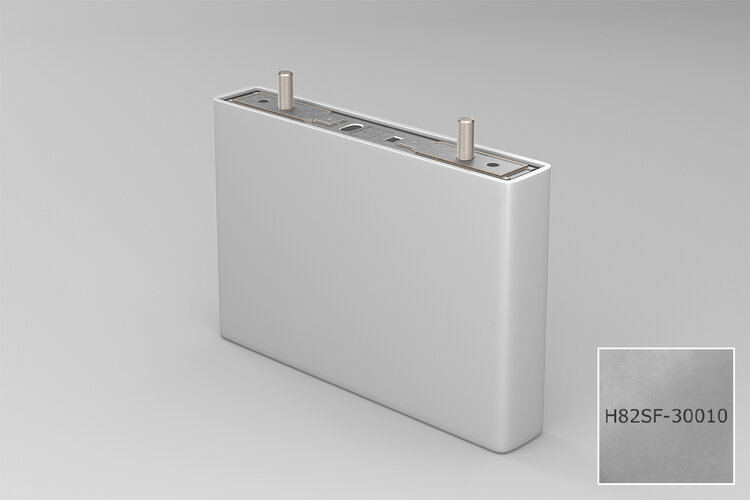

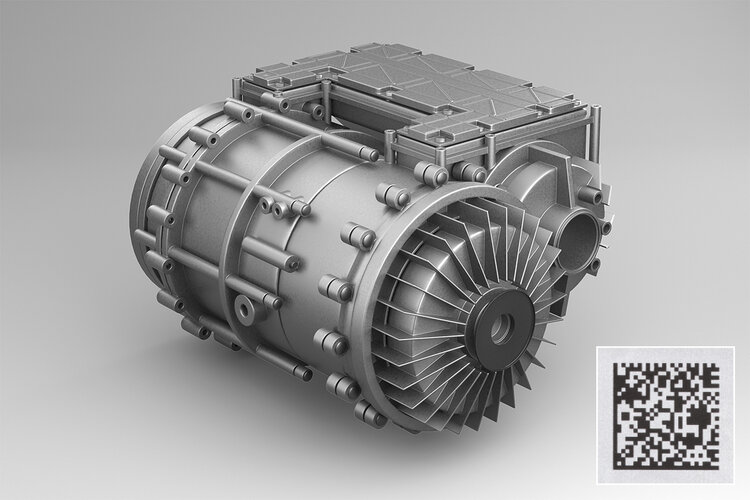

Applications

Downloads

| Name | Size | Date | Language |

|---|---|---|---|

| Brochure: Laser Marking Systems - Overview | 5 MB | 01.02.2024 | en |

| Brochure: Laser Systems - Service | 2 MB | 01.03.2024 | de |

| Brochure: Laser Systems - Service | 2 MB | 01.03.2024 | en |

| Spare Parts List | 480 KB | 01.04.2024 | en |

| Broschüre Lasermarkiersyste - Übersicht | 5 MB | 28.02.2024 | de |

| Name | Size | Date | Language |

|---|---|---|---|

| Form: Service Request | 814 KB | 01.12.2022 | de |

| Form: Service Request | 811 KB | 27.10.2022 | en |

| Form: Sample Marking Request | 6 MB | 06.05.2022 | de |

| Form: Sample Marking Request | 1 MB | 06.05.2022 | en |

| Name | Size | Date | Language |

|---|---|---|---|

| Übersicht Topseller Automatisierungstechnik, 6215eude | 3 MB | 02.05.2024 | German |

| Top seller - Automation products, 6215euen | 3 MB | 01.05.2024 | English |

| Les essentiels - Produits d’automatisme, 6215eufr | 5 MB | 16.06.2023 | French |

| Name | Size | Date | Language |

|---|---|---|---|

| Whitepaper: Traceability | 1 MB | 30.10.2023 | de |

| Whitepaper: Traceability | 884 KB | 30.10.2023 | en |