MOSFET relays from Panasonic: wide range of future-oriented semiconductor technology

Panasonic Industry Europe is a manufacturer of relays, solid state relays, switches, and connectors. With its portfolio of PhotoMOS® relays, the company offers a globally unique product spectrum: choose the appropriate solutions for virtually any application area from over 400 different types.

The Panasonic range includes two types of semiconductor relays: solid state relays (SSR) for switching medium to high loads - typical consumers include heating elements, ventilation systems, valves, pumps, or motors. The second group is the PhotoMOS® relays, also known as MOSFET relays, which offer a particularly wide range of applications.

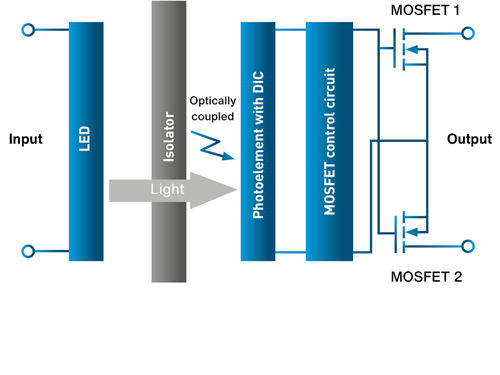

Design and function of a MOSFET relay

MOSFET relays consist of a light-emitting diode (LED) on the input side. Its emitted light hits an array of solar cells after passing through a semitransparent insulator material. There, the incoming light is converted into electrical voltage. Via a trigger circuit, the output voltage generated in this way controls the gates of two bidirectionally connected MOSFETs at the output. The MOSFETs’ anti-serial circuit connection enables both DC and AC loads to be switched. Due to the use of MOSFETs, MOSFET relays differ significantly from optocouplers and solid state relays with triac or transistor modules

What makes MOSFET relays so successful on the market?

MOSFET relays offer numerous advantages: the underlying semiconductor technology enables silent as well as bounce- and wear-free switching at high switching frequencies. Since MOSFET relays contain no moveable contacts, they are renowned for their high reliability and longevity. Regardless of the number of switching cycles, MOSFET relays offer a virtually unlimited service life as long as they are operated in-line with the recommended specifications. Mechanical wear or sensitivity to vibrations or mechanical shock do not play a role where MOSFET relays are concerned.

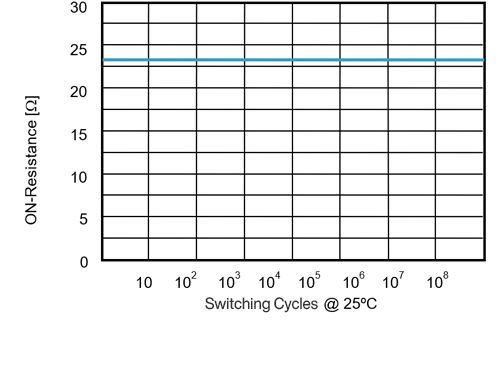

Unlike electromechanical relays, in which various effects can influence the contact resistance, the ON resistance of MOSFET relays remains constant throughout the entire service life.

The illustration here shows a curve using the AQV210E as an example.

The integration of the latest MOSFET technologies enables load voltages of up to 1,500 V AC (e.g., AQV258 family) or load currents of up to 10 A DC (AQZ192) to be switched. MOSFET relays only need a very low LED current of around 5 mA on the input side. Special types that require a current of just 2 mA are suitable for particularly energy-sensitive applications.

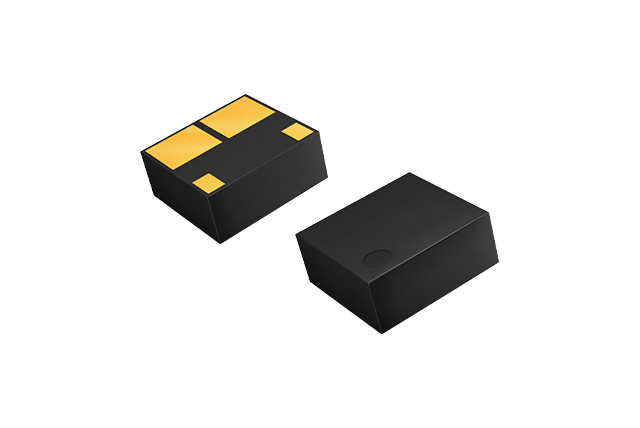

The semiconductor technology enables MOSFET relays to be integrated into extremely small structures such as TSON (e.g., AQY2C1R2P with a switching capacity of 40 V/0.3 A with an ON resistance of only 0.8 Ω) or VSSOP (e.g., AQY221N5T with an output capacity of just 0.4 pF).

The PhotoMOS® app offers a very simple option for filtering by structures.

The app, which is available for iPhones and iPads, can be downloaded here.

MOSFET relays are typically used in the areas of measurement technology, automation and control technology, smart metering, and in the rapidly growing automotive market, focusing on electric vehicles and e-mobility.

MOSFET relays - advantages at a glance

- Silent switching

- Linear output characteristic

- Low current consumption

- Low off-state leakage current

- No threshold voltage

- Stable ON resistance throughout the entire service life

- High reliability with extremely long service life

- Very compact size

- Fast switching speed

- High vibration and shock resistance

- No bounce or switching noise

Operating principle and potential applications of MOSFET relays

The term “relay” describes the component’s operating principle. A control signal on the input side enables a circuit connected on the output side to be made or broken. The relay encompasses galvanic isolation between the control (input side) and the load circuit (output side). In the e-mobility sector, for instance, this enables the high-voltage battery’s voltage to be switched to a safely low, touchable voltage level by means of a signal. Thanks to the insulation, the user does not have to be concerned about any arc-over.

The prefix “MOSFET” describes the circuit element integrated on the output side. Specifically, this usually involves two power MOSFETs that are connected anti-serially to enable both AC and DC loads to be switched. In simplified terms, a MOSFET can be regarded as a voltage-controlled resistor. Depending on design, both making and breaking MOSFETs exist, meaning that the connected circuit is either made or broken when the MOSFET is not activated. In the context of relays, these are therefore referred to as normally open (form A) or normally closed (form B) components.

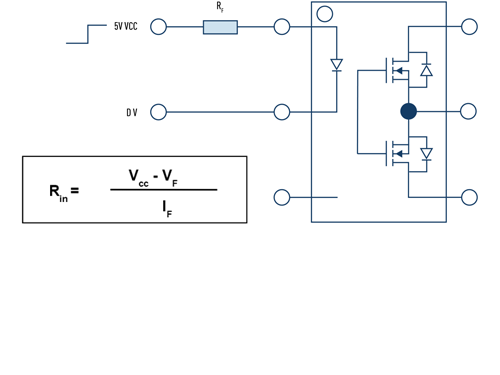

Important considerations when designing circuits with MOSFET relays: input voltage

An external limiting resistor is needed to activate the MOSFET relay. When the control voltage is applied to the input side of the component, a voltage drop occurs at the LED. An accordingly dimensioned limiting resistor must be added to limit the LED current to the value recommended by the manufacturer.

Attention must also be paid to the ambient temperature when dimensioning the limiting resistor. To do this, the LED voltage drop at the maximum ambient temperature that occurs should be taken into consideration when calculating the limiting resistor.

- VCC: Supply Voltage

- VF: LED Drop-Out Voltage (typ. 1,25V)

- IF: PhotoMOS® LED Current

- Rin: Limiting Resistor

If the LED is operated with a permanently high current or at a high temperature, the LED suffers and degrades over time. Conversely, no noticeable impairment of the efficiency and therefore the service life of the MOSFET relay are to be anticipated if these values lie in the range recommended by the manufacturer.

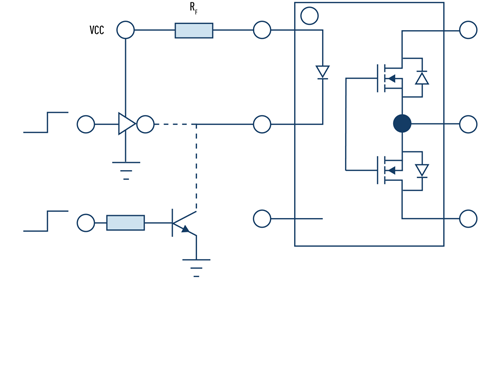

Transistors as activation elements

Some logic circuits do not supply sufficient current to power MOSFET relays directly. This can be remedied by using an additional transistor or a CMOS inverter.

The illustration shows the input circuit of a MOSFET relay with a transistor and the additionally necessary external power supply. In this scenario, the transistor is controlled by the logic circuit output and the corresponding LED current is provided by the external source. The voltage drop between the collector and the emitter of the transistor must additionally be taken into consideration when calculating the limiting resistor for the LED.

AC, DC, high currents: connection options for PhotoMOS® relays on the load side

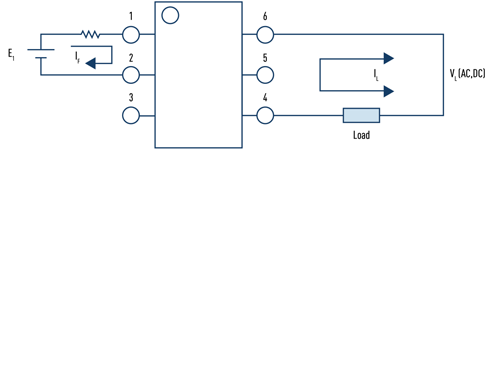

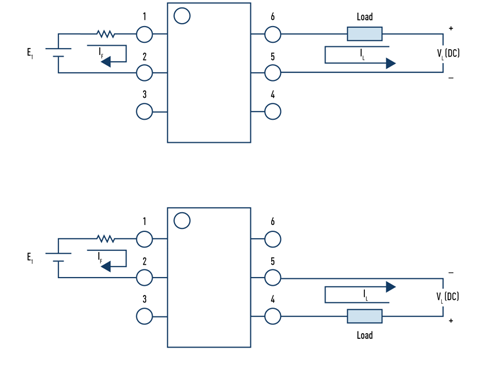

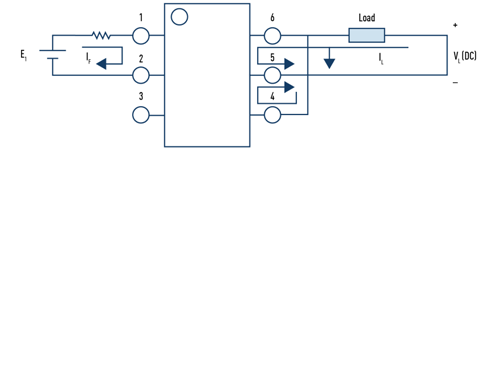

In the case of dual-channel MOSFET relays (2 Form A AQW types, e.g., AQW216AZ), various circuit options are available for meeting different load requirements. The following illustrations show this using the example of MOSFET relays in a 6-pin package.

Circuit A uses both internal MOSFETs in an anti-serial circuit connection. This therefore enables both AC and DC loads to be switched between pin 4 and pin 6.

Conversely, if only pin 6 and pin 5 or pin 4 and pin 5 are used to connect the load circuit, as shown in circuit B, only one MOSFET is used to switch the load. In this configuration, only DC loads can be switched by the MOSFET relay. Attention must therefore be paid to the polarity on connection. In this configuration, only the ON resistance of a MOSFET contributes to the heat build-up in the component package. The current strength can therefore be increased a little before the limit is reached.

In circuit C, both MOSFETs are connected in parallel in order to switch a DC load. This therefore halves the ON resistances of the MOSFETs and twice the current can be switched by the MOSFET relay. Attention must therefore be paid to the polarity on connection.

The application topology determines the MOSFETs that are used

The topology and structure of the desired solution as well as aspects such as current consumption, output capacity, frequency response, and insulation capability are important parameters and criteria for selecting suitable MOSFET relays. Focus is placed on component size and frequency response in measurement applications, whereas the output power and I/O insulation often play a more major role in the field of industrial automation.

Important technical aspects

The losses that are incurred also have to be taken into consideration when selecting the right MOSFET relay. To do this, three values have to be analyzed in the specifications:

- What current consumption does the component need for operation?

- What off-state leakage current occurs at the output side in switched-off status?

- Which losses occur when conducting the load?

The latter is calculated from the ON resistance at the current ambient temperature and the load current to be conducted.

Panasonic offers a wide range of different MOSFET relays and MOSFET drivers for your technical solution. You can’t find an appropriate component? We will be more than happy to offer customer-specific special types.

The MOSFET relay portfolio from Panasonic

PhotoMOS® relays from Panasonic – maximum possible choice in terms of requirements, package sizes, properties, and target applications – find exactly the right solution for your need.

With its extensive portfolio of MOSFET relays, what are called PhotoMOS®, Panasonic offers a wide selection of various switching solutions.

From the TSON micro package for high-density equipping to the power PhotoMOS® with high load capacity – you’re sure to find the ideal PhotoMOS® for any application among more than 400 various types in 18 different package variants.

MOSFET relays from Panasonic support numerous industrial sectors and application areas

High output power

With a current load capacity of up to 10 A DC (6 A AC), the MOSFET relays in this product group are supplied in the narrow SIL package or in the particularly low and compact PowerDIP version.

- Stationary energy storage systems

- Photovoltaic systems

- Robotics

- Industrial automation

- Automotive

Low ON resistance

Thanks to low ON resistances down to 8 milliohms (AQZ192), HE and HF series PhotoMOS® enable you to minimize losses and heat input in your application despite higher currents.

- Office automation

- Measurement applications

- Industrial machines

All-rounders

The GU series and GE series types are the bedrock in the medium-power range and are suitable for a variety of applications. To reduce energy consumption, the high-sensitivity types are equipped with an LED with very low current requirements.

- Data communication

- Monitoring systems

- Robotics

- Measurement applications

Low CxR

The RF series PhotoMOS® relays have a low ON resistance and a low output capacity in common. These so-called LowCxR types display outstanding high-frequency characteristics and enable a high channel density thanks to their particularly small structures.

- Data communication

- Measuring instruments

- Medical technology

MOSFET relays for automotive applications

The Panasonic PhotoMOS® portfolio also encompasses special types for use in the automotive sector. They are commonly used in and around the battery management system (BMS) in electric vehicles, for instance. Reed relays are increasingly being replaced by MOSFET relays in applications such as insulation monitoring or high-voltage measurement. MOSFET relays offer major advantages in these application areas thanks to their long service lives and outstanding robustness. Please get in touch with our sales contacts if you would like to use MOSFET relays from Panasonic in an automotive application.

Selection by package type

Since the ON resistance leads to power loss, the resulting heat has to be dissipated via the package surface. The application’s current and voltage parameters therefore extensively determine the package size to be selected:

Choosing the right PhotoMOS® relay is crucial to success and depends on a number of important factors that have to be taken into account – no mean feat.

The free Panasonic PhotoMOS® app (for iPhone & iPad) therefore helps you to choose the right PhotoMOS® relays for your individual application areas. Its clear arrangement and intuitive navigation help the user to quickly find the optimal component.