Meet kinari - a sustainable alternative for plastic

Introducing kinari

Eco-friendly production process

What sets kinari apart is its eco-friendly production process, which significantly reduces CO2 emissions compared to traditional methods. The material utilizes a diverse range of waste substances, such as used coffee grounds, excess trees cleared from woodland, and residues from sake brewing, eliminating pressure on the food supply chain.

The environmental impact of petroleum-derived plastics

Petroleum-derived plastics have become a pressing global environmental issue, with usage reaching a staggering 300 million tons per year. The detrimental effects of plastic pollution and carbon emissions are well-documented, yet the global recycling rate for plastic remains dismally low at just 9%. This calls for urgent action to find sustainable alternatives and reduce our reliance on petroleum-based plastics.

Panasonic's pioneering efforts

Recognizing the need for change, Panasonic embarked on a mission to reduce the usage of petroleum-derived plastics back in 2015. The company has been at the forefront of developing innovative solutions that offer sustainable alternatives to traditional plastics. By leveraging cellulose fiber sourced from plants, Panasonic aims to create a more environmentally friendly approach to plastic production.

Introducing kinari - a high-performance bioplastic solution

One of Panasonic's key bioplastic solutions is kinari, a high-performance material that contains up to 85% cellulose. Despite its plant-based composition, kinari exhibits properties comparable to those of petroleum-based resins. This breakthrough in bioplastics opens up new possibilities for reducing the environmental impact of plastic usage without compromising on performance.

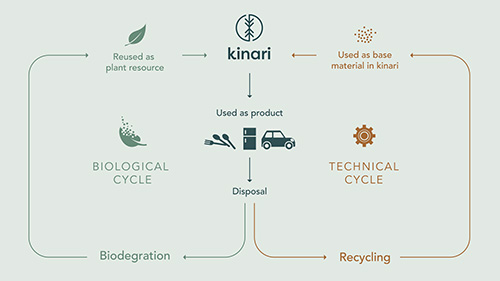

Driving towards a circular economy

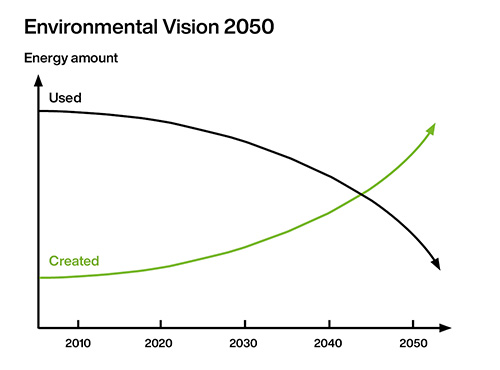

Panasonic's commitment to sustainability extends beyond the development of bioplastic alternatives. The company envisions a circular economy, where resources are used efficiently, and waste is minimized. Through initiatives like Panasonic Green Impact (PGI), the company aims to create a society that embraces recycling, reusing, and reducing plastic waste. By collaborating with Japanese and global companies, Panasonic is actively working towards realizing this vision.

In conclusion, Panasonic is leading the charge in finding sustainable alternatives to petroleum-derived plastics. With kinari and other innovative solutions, the company is paving the way for a more environmentally friendly approach to plastic production. By embracing a circular economy and promoting recycling, Panasonic is committed to reducing plastic waste and creating a more sustainable future for generations to come.