GT03-E Tough touch terminal

The GT03-E Tough panel for applications under rough conditions

New models are added to the GT Tough series: the GT03-E compact models. It is the industry's smallest body in the class of 3.5 inch screens (based on a research conducted by our company in February, 2013) and is designed for a wide range of applications, e.g. charging station for electric vehicles, car washing machines, coin-operated parking or food filling machines.

PLC program transfer without the use of a PC

It is possible to modify PLC programs as well as the GT screen programs by using an SD/SDHC memory card. SD/SDHC memory cards can be used to easily update PLC programs.

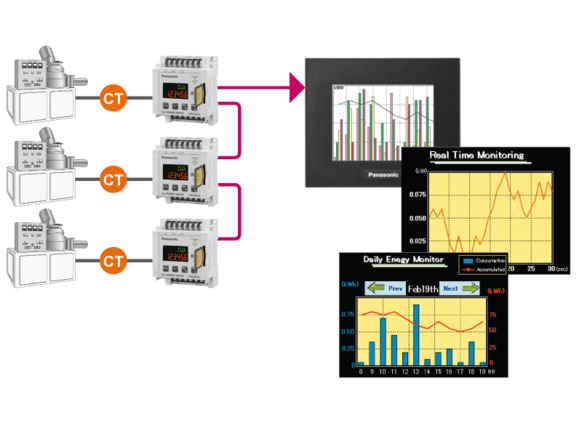

SD logging function for data visualization

Capable of automatically collecting electrical power readings of Eco-POWER METERS on an SD/SDHC card and displaying them in a real time graph, the GT Tough panels allow users to take quick actions. The portable SD/SDHC memory cards can be used to store large volumes of data. Data visualization is possible without requiring a PC as a display or a data logger for collecting data. One bar graph has a maximum of eight bars and can be combined with line graphs. The following three conditions can be selected to trigger an operation to save log data:

- Specified time

- Specified cycle (1 sec. to 24 hrs.)

- Specified condition

Large volumes of data can be saved on a portable SD/SDHC memory card.

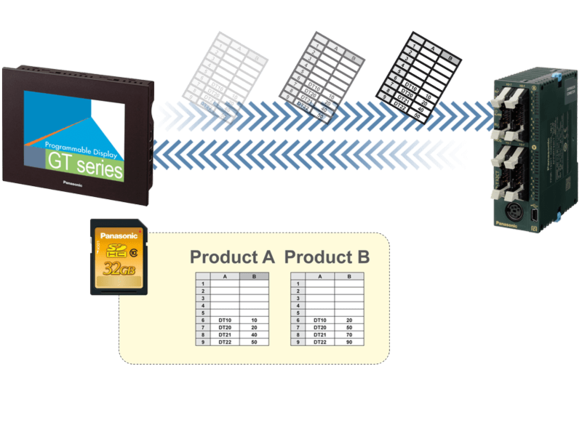

SD recipe function

For high-mix production, recipe data of up to 64 types and 4096 devices in total can be easily set on a PC. The created recipe data are saved on an SD/SDHC memory card, and the specified data can be written or read from a PLC.

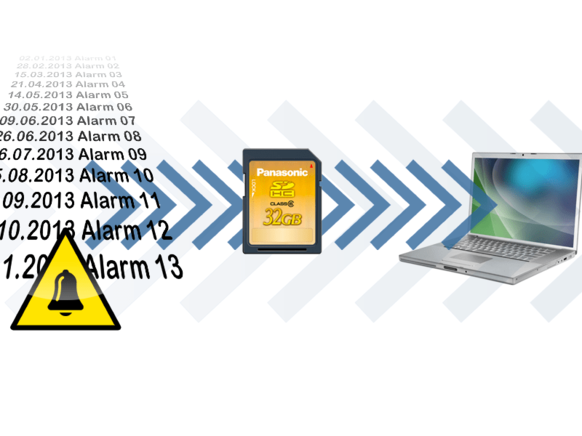

Saving alarm history data on an SD/SDHC memory card

The alarm history data stored in the GT built-in memory can be saved on an SD/SDHC memory card, making it possible to easily control problems on a PC.

Highly flexible screen design

The GT series displays use an analog touch panel where locations of parts and characters can be adjusted in increments of one dot. The adoption of the Windows® font has widened the character size selection (10 to 240 dots), making the screen design more flexible.

Newly equipped with an FP monitoring function

The setting status and data of our FP series PLCs connected to GT panels can be monitored and edited on the GT screen. This function allows you to check equipment operation in actual environments without creating screens in advance or connecting the unit to a PC. Furthermore the efficiency of equipment startup and daily maintenance work is increased.

Notes:

- The FP monitoring function is available for FP-X, FPΣ, FP0H, FP0R, FP2, FP2SH, FP0, and FP-e.

- The FP monitoring function can be used only when the FP monitoring screen is stored in GT panels. Note that the FP monitoring screen uses the user memory (F-ROM) of GT units.

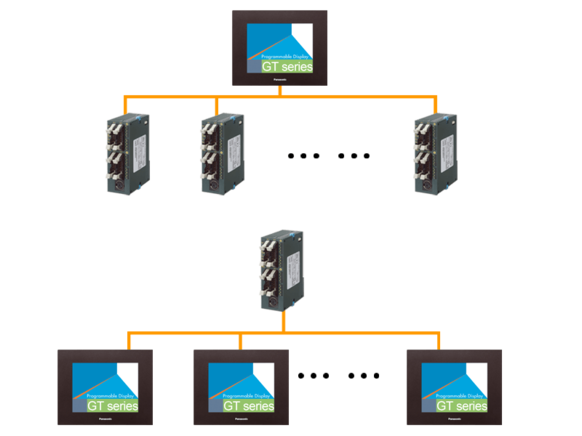

Multiple GT displays can be connected to our FP series PLCs

GT link function

Up to 32 GT displays can be connected to one PLC unit without communication programs. The same screen operation is possible at a conveyor line or other remote locations, and the number of PLC units can be reduced, cutting the production process costs.

Connectivity with multiple PLCs

Up to 31 PLC units can be connected to one GT unit. Progress in multiple production lines can be centrally monitored and controlled via one GT unit.

Enhanced security with password protection

Password protection and operation security functions protect the technical plant data in the display unit and control the authorization for operation.

Password protection function

The screen data upload operation can be restricted by using passwords to protect the technical plant data in the display unit.

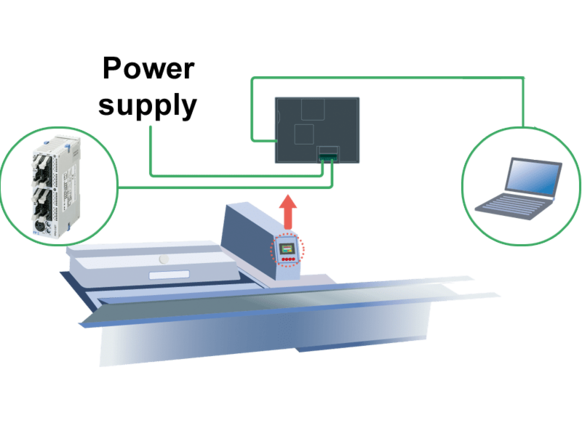

High-efficiency operation with through function

This function allows operators to simultaneously carry out the transfer of screen data of a GT series display and the debugging of our FP series PLCs connected to the display. GT03-E supports Ethernet connection, which allows the through function to be controlled from a remote location.

Easy-to-switch language

Normally, screens were created for each language. With the new language switching function, data can be registered in multiple languages (up to 16) for each part. The characters can be easily edited with Microsoft Excel® and then imported.

Write device function

This function modifies the PLC data or turns bits on or off according to the PLC status or screen no. Now four arithmetic operations between devices are possible.

Specifications

| GT03M-E | GT03T-E | |||

|---|---|---|---|---|

| Part number | AIG03MQ03DE | AIG03MQ05DE | AIG03TQ13DE | AIG03TQ15DE |

| Rated voltage | 24V DC | |||

| Power consumption | 1.9 W or less | 3.1 W or less | ||

| Display | ||||

| Screen size (W x H) | 3.5" (70.6 x 52.9) | |||

| Display device | TFT monochrome LCD | TFT color LCD | ||

| Display color | 2 colors (black/white, 16 shades of gray) | 4096 colors | ||

| Resolution (W x H) | 320 × 240 dots | |||

| Backlight | White LED | |||

| Memory capacity (F-ROM) | 6.144kB | |||

| External interface | ||||

| Serial port | RS232C | RS422 (RS485) | RS232C | RS422 (RS485) |

| USB-port | X | X | X | X |

| Ethernet | -- | |||

| SD-memory card | -- | X | ||

| Sound output jack | -- | |||

Downloads

| Name | Size | Date | Language |

|---|---|---|---|

| AIP81862E1D - Kommunikationskabel zwischen PC COM-Port, FPWEB Modem COM, GN-Panel und FP2-COM-Port, FP2-MCU-RS232, AIP81862E1D | 42 KB | 15.02.2023 | German |

| Name | Size | Date | Language |

|---|---|---|---|

| CAD files GT03-M as IGES(igs), STEP(stp), Parasolid(x_t) and DXF(dxf) | 519 KB | 12.04.2013 | English |

| CAD files GT03-E as IGES(igs), STEP(stp), Parasolid(x_t) and DXF(dxf) | 797 KB | 01.07.2013 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Data sheet GT03-E / GT32-E | 1 MB | 04.10.2023 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Terminal GTWIN Ver.3 Operation Guide Book, WUME-GTWINV3-02 | 3 MB | 10.04.2024 | English |

| GT Series User's Manual, WUME-GTH-05 | 16 MB | 09.04.2024 | English |

| GT Series RTU Slave Modbus Manual, WUME-GTMODBUS-01 | 2 MB | 09.04.2024 | English |

| GT Series Connection To Other Companies PLCs Manual | 6 MB | 23.03.2022 | English |

| GT Series General Purpose Serial Communication Manual, WUME-GTCOM-01 | 3 MB | 09.04.2024 | English |

| Terminal GTWIN Ver.3 Reference Manual, ACGM0357V18EN | 7 MB | 30.10.2024 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Bediengeräte HM-Serie und GT-Serie, 4253dlde | 6 MB | 01.12.2023 | German |

| Humane Machine Interface: HM series and GT series, 4253euen | 5 MB | 31.01.2025 | English |

| Interface homme-machine: Séries HM et séries GT, 4253 eufr | 6 MB | 01.12.2023 | French |

| Brochure "Focus Automazione" | 8 MB | 08.01.2025 | Italian |

| Name | Size | Date | Language |

|---|---|---|---|

| FPGT Loader, Version 2.4.2.0, is a utility for up-/downloading data to and from GT panels (GT01, GT02, GT03-E, GT11, GT21, GT05, GT12, GT32, GT703, GT704, GT707, GT710) and PLCs (FP0, FP0R, FP-e, FP-SIGMA, FP0H, FP-X, FP-XH, FP7). FPGT Loader can be used to make true copies of a master GT or a master PLC project to one or more target GTs or PLCs. For Windows 10 and 11. | 297 MB | 22.12.2025 | English,German,Spanish |

| GT programming software GTWIN Ver.3.47 Update Version. For GT703/704/707/02/02L/03-E/05/12/32/32-R/32-E. This software works with Windows 10 and 11. | 200 MB | 09.05.2025 | English, German, Japanese, Chinese Simplified, Korean, Russian, Vietnamese, Turkish |