MINAS A6SF servo driver

Overview

- 50W to 5kW, 1/3-phase, 200V

- 200W to 5kW, 3-phase, 400V

Response frequency of MINAS A5: 2kHz bandwidth (velocity response)

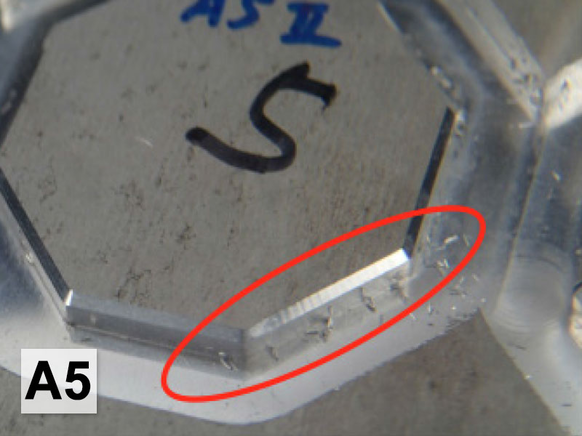

Fast response allows precise processing of metal surfaces

Figure: Numerous interference bands

Ultrafast response frequency of MINAS A6: 3.2kHz bandwidth (velocity response)

Smooth surface, like a mirror!

Figure: Hardly any interference bands

Real-time auto-gain tuning

Automatic tuning after completion of multiple operations.

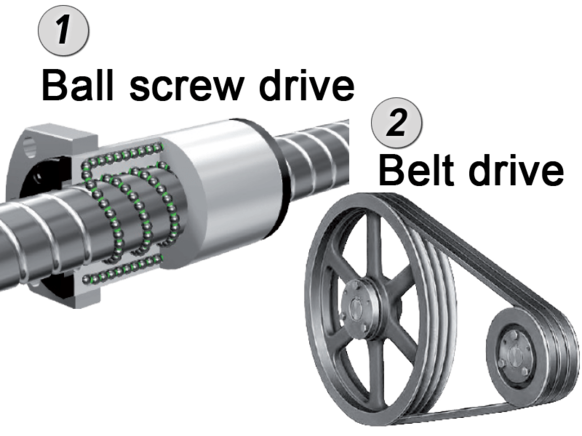

The automatic vibration suppression function minimizes damage to the equipment. Additional mode and stiffness parameters enable easy response frequency-optimization for specific machine types such as high-friction, belt-driven machines or machines with low-friction ball screw drives.

Figure: Drive types

- Ball screw drive

- Belt drive

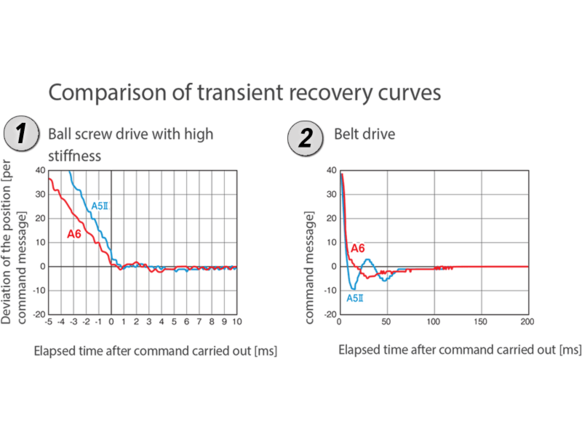

Improved vibration suppression

Vibrations when braking to a standstill have now been significantly reduced. This has shortened the transient recovery time considerably.

Figure: Comparison of transient recovery curves

- Ball screw drive

- Belt drive

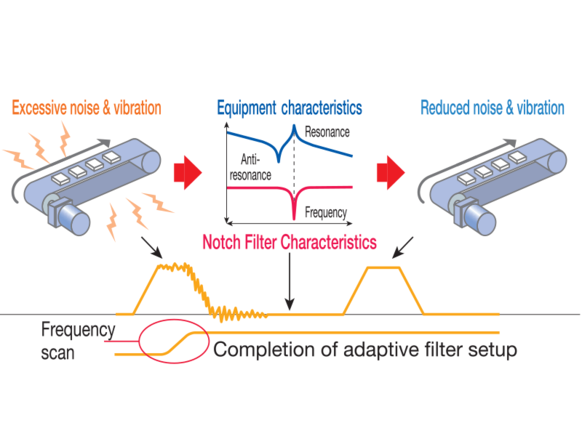

Manual and automatic notch filters

Highly sensitive notch filters log vibration frequencies and adapt them automatically.

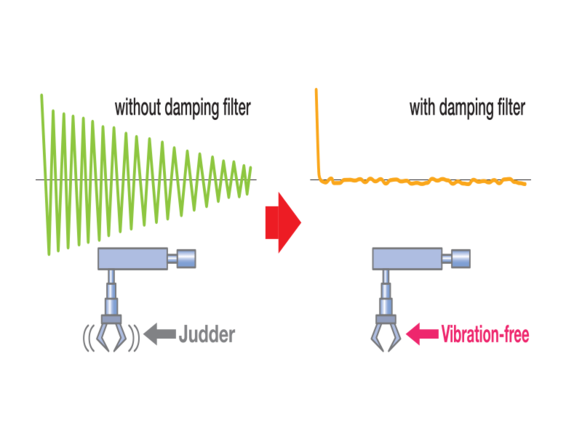

Manual and automatic damping filters

Damping filters that can be set automatically suppress the equipment's resonance and the natural vibration frequency component of the command input, which greatly reduces axis vibration at machine stoppage.

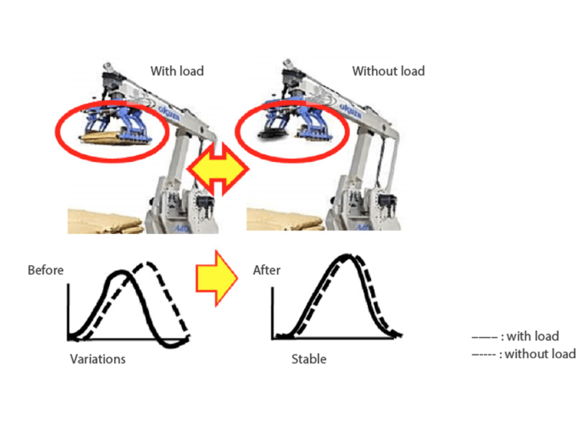

Improved suppression of load variations

- Reduction of transient recovery time during positioning

- Stable movement for multiple-joint robot With / without load or with variable load

Semi/fully enclosed position control loop

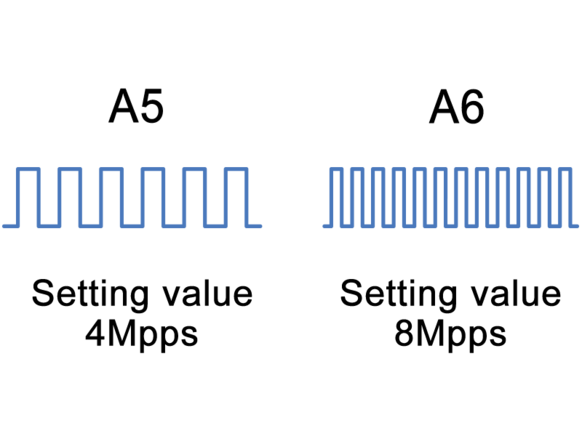

The A6 series enables a setting value of 8Mpps and a response with 4Mpps. This allows for high resolution as well as high-speed operation.

Figure

A5: Setting value 4Mpps

A6: Setting value 8Mpps

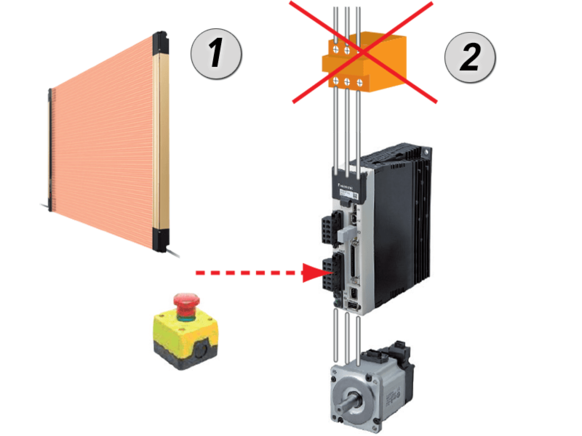

Integrated safety function STO (Safe Torque Off)

Safety functions based on safety standards:

ISO13849-1 (PLe, CAT3), EN61508 (SIL3), EN62061 (SILCL3), EN61800-5-2 (SIL3, STO), IEC61326-3-1, IEC60240-1.

Figure:

- Safety equipment

- Electromechanical safety shutdown

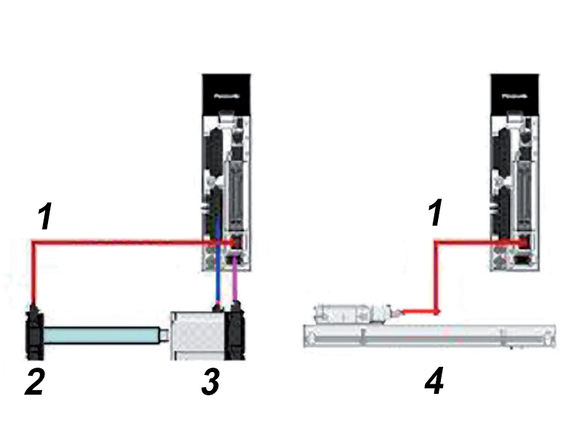

External encoders for full-closed control

Using an external encoder ensures high-precision position control.

Figure:

- Feedback

- External encoder

- Motor

- Linear scale

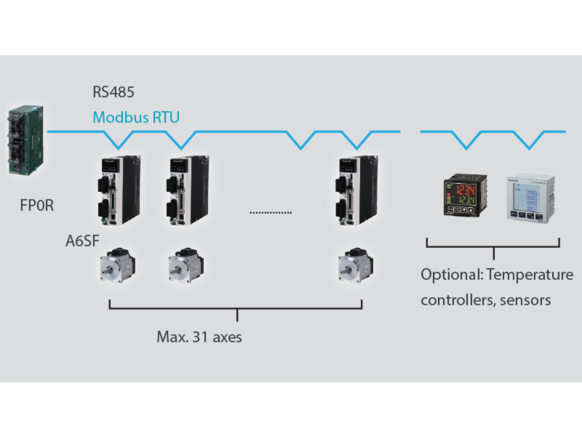

Modbus RTU: Simple complete motion control solution with one Panasonic compact PLC

- Modbus RTU is an open, serial (RS232 or RS485) protocol based on a master/slave or client/server architecture.

- Widely used protocol due to its ease of operation and reliability.

- Cost-effective solution for programmable controllers based on RS485.

- Servo drives can be controlled based on a CANopen CiA drive profile

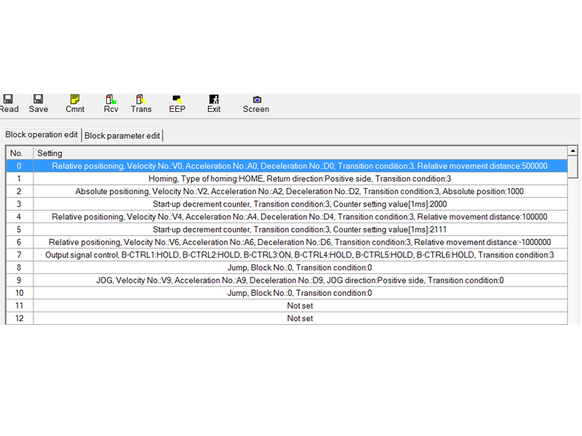

Block operation with digital I/Os (like MINAS A4P)

Up to 256 block can be controlled via I/O terminal units, PLCs, switches, etc.

Functions

| Type | Basic A6SE |

RS485 communication A6SG |

Multifunction A6SF |

Network | |

|---|---|---|---|---|---|

| A6N | A6B | ||||

| RTEX | - | - | - | x | - |

| EtherCAT | - | - | - | - | x |

| External encoder | - | - | x | x | |

| Safety function STO | - | - | x | x | |

| RS232/485 (Modbus) | - | x | x | - | |

| Velocity control, torque control | - | - | x | x | |

| Position control with dig. I/O (like MINAS A4P) | x | x | x | - | |

| Position control | x | x | x | x | |

Specifications

| MINAS A6 series | A6SE | A6SG | A6SF | A6N | A6B |

|---|---|---|---|---|---|

| Rated power | 50W–5kW (200V AC), 200W–5kW (400V AC) | ||||

| Supply voltage | 1/3-phase (200V AC), 3-phase (400V AC) | ||||

| Bandwidth (velocity response) | 3200Hz | ||||

| Rated rotational speed | 2000–3000rpm | ||||

| Max. rotational speed | 3000–6500rpm | ||||

| Rated torque | 0.16–15.9Nm (200V AC), 0.64–23.9Nm (400V AC) | ||||

| Peak torque | 0.48–47.7Nm (200V AC), 2.23–71.6Nm (400V AC) | ||||

| Control functions | Position control | Position, velocity, and torque control | |||

| IP degree of protection (motor) | IP67 | ||||

| Control input | Pulse | Pulse, analog | Network | ||