Laser Welding Technology

Panasonic Laser Welding Series VL-W1

High quality and precision plastic joinings

The VL-W1 Laser welding system is equipped with our original FAYb fiber laser. It is based on the technologies we have accumulated in the last decades through the manufacturing of laser marking systems. The new Laser welding system VL-W1 has taken the proven and tested fiber technology one step further and guarantees welding results of the highest quality.

Laser welding method

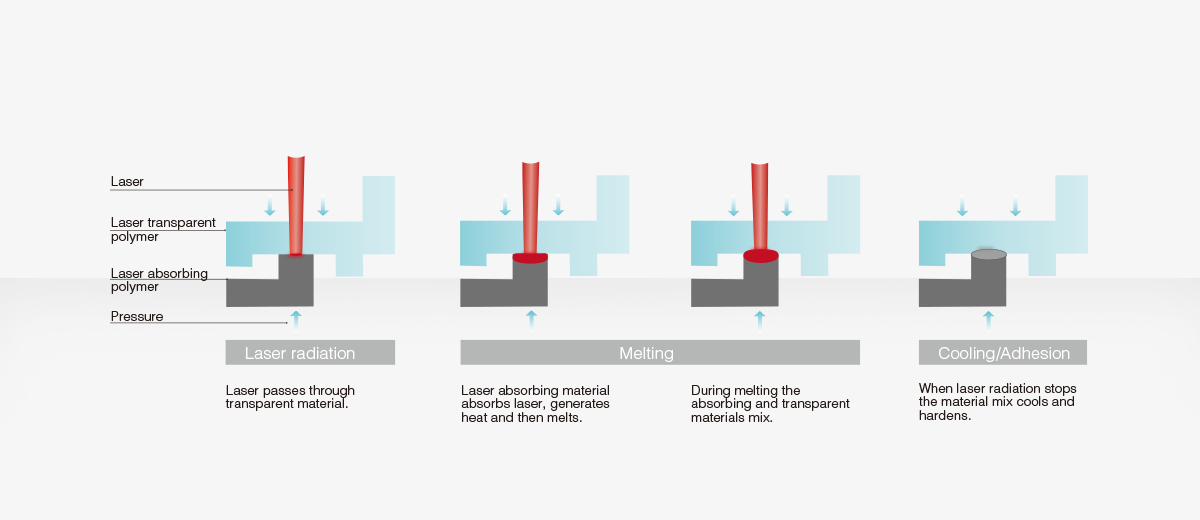

The new laser welding system of the VL-W1 series is based on the technology of quasi-simultaneous welding. With this method, plastic layers can be welded together by laser emission and heat build-up at the adjacent surfaces without the need for adhesives. One of the characteristics of the quasi-simultaneous welding is that the laser beam is directed very fast (quasi-simultaneously) around the component to be welded. Main advantage: the component is joined together regularly so that no warping occurs. Furthermore, using the laser guarantees a high flexibility of the welding seam geometry.

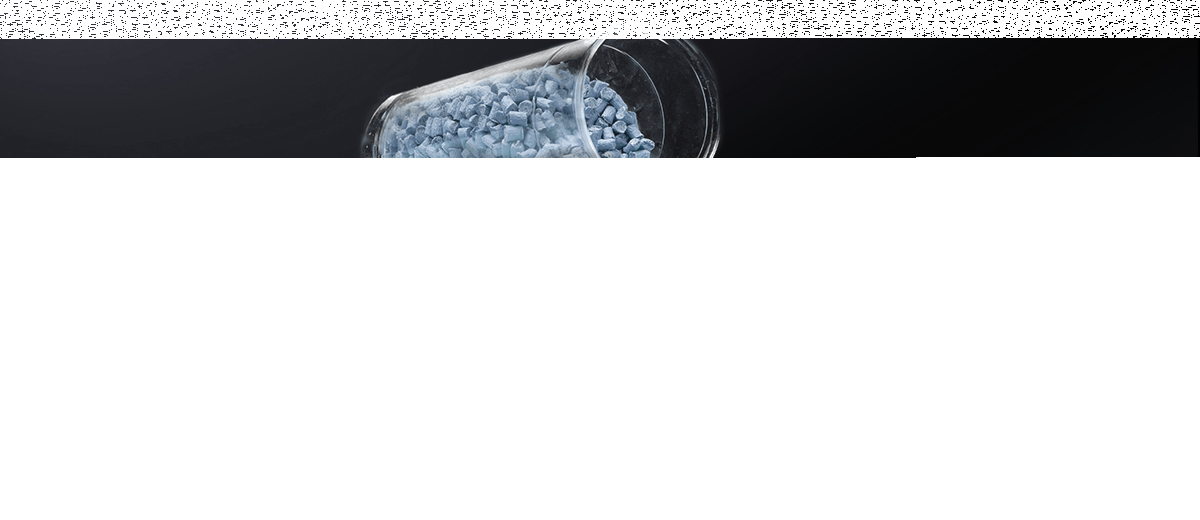

Weldable plastic materials

Which plastic materials can be welded by the Panasonic VL-W1? The materials may consist of elastomers, semi-crystalline, and amorphous plastics. Basically, the component should consist of one transparent and one absorbing material. The laser beam passes through the laser transparent (upper) material and then is absorbed by the laser absorbing (lower) material. The laser-absorbing material heats up and melts together with the laser-transparent material by heat transmission. During welding, a joining pressure adapted to the needs of the workpiece supports a precise junction of the plastic components.

Level of difficulty of material combinations

Applications with black joining parts combined with transparent, black or colored plastics are standard applications. Pure colored, transparent, and white materials increase the level of difficulty during overlap welding. For welding colored plastics, the necessary combinations of colorants in laser transparent and laser absorbing form are developed at the request of the customers. This is a typical task for the experienced masterbatch manufacturer – we have partners with long years of experience. Due to its scattering properties and its low transparency, “white on white” represents the highest level of difficulty, but also in this case individual solutions are possible.

Please send us your samples with color and material combination. We will develop your sample solution.

Do you want to mark your products with a laser?

If yes, please send us some samples and we will show you the best-quality laser marking for your product and application. We are happy top advise you when you send us your requirements together with some samples - simply fill in the request form and let us convince you of the quality of Panasonic's laser marking.

Fill in the request form and send it together with your samples to:

Panasonic Industry Europe GmbH

Laser Marking and Processing Laboratory

Maria-Merian-Strasse 7

85521 Ottobrunn

Germany

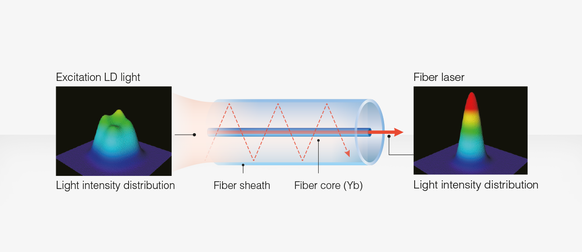

Highest laser beam quality

The VL-W1 series is equipped with our original, high-performance fiber laser developed based on the technologies we have accumulated through the manufacture of laser marking systems. This fiber laser achieves high-quality welding results.

Thanks to the unique oscillation principle of the Panasonic fiber laser, the fiber can be used as an amplification medium. Since light can be amplified inside an extremely thin fiber core, a laser light with a high beam quality can be obtained. Thus, less energy is required and a stable beam from the first processing step till the end of production is guaranteed.

The picture illustrates the difference of light intensity distribution between the laser diode light and the fiber laser.

With the exact and parallel light of the VL-W1, component weldings on complex surfaces can be realized. Thus, processing with a height difference of +/- 15 mm is possible. 3D component geometries can be welded flawlessly.