Download our promotion documents

| Name | Size | Date | Language |

|---|---|---|---|

| Products Catalog (Film Capacitors) | 18 MB | 08.11.2023 | English |

| Devices & Solutions catalogue | 12 MB | 02.09.2025 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| DC Filtering Capacitors: EZPV Series | 640 KB | 08.07.2024 | English |

| PFC/Smoothing/Filtering Capacitors: ECWFG Series | 639 KB | 08.07.2024 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Automotive & Industrial Film Capacitors | 812 KB | 23.02.2026 | English |

| Panasonic Focus 8 colors flyer | 650 KB | 02.09.2025 | English |

| AEC-Q200 Passive Components Selection Guide.pdf | 1 MB | 18.12.2025 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Panasonic - Film capacitor - Selection tool (Feb. 2026) | 3 MB | 10.12.2025 | English |

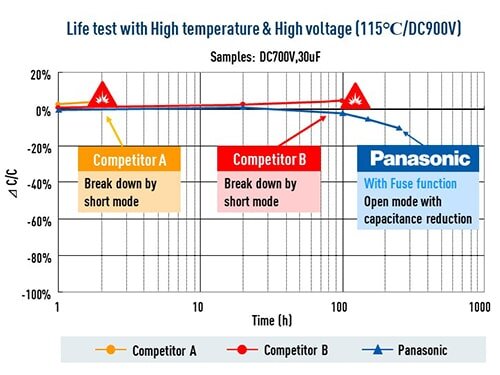

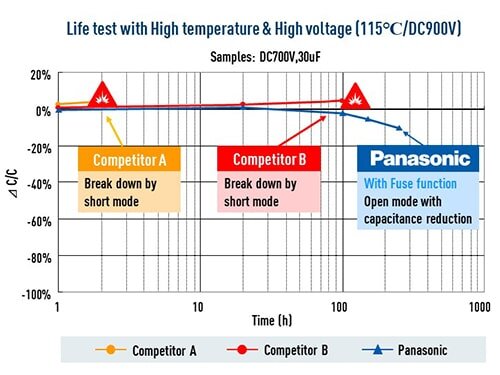

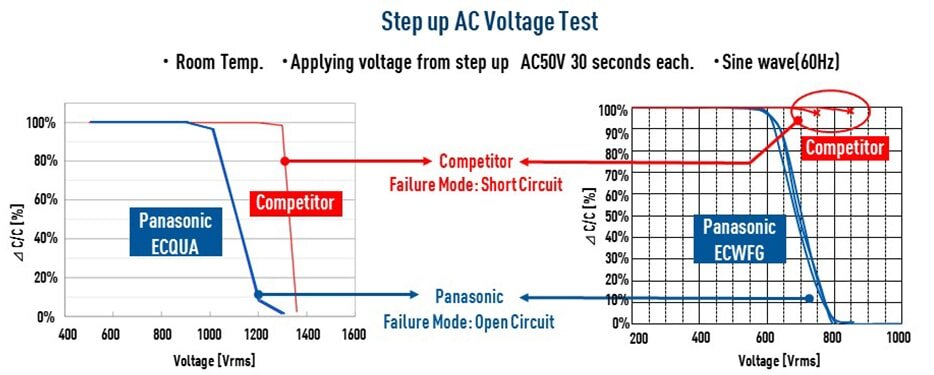

High safety and long life thanks to a built-in fuse function

The damage caused by over-voltages on non-fused material is far more extensive than that suffered by fused material. Therefore Panasonic's film capacitors are the ideal solution for high stress applications.

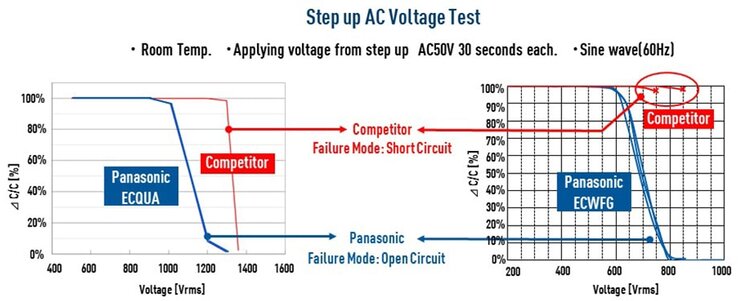

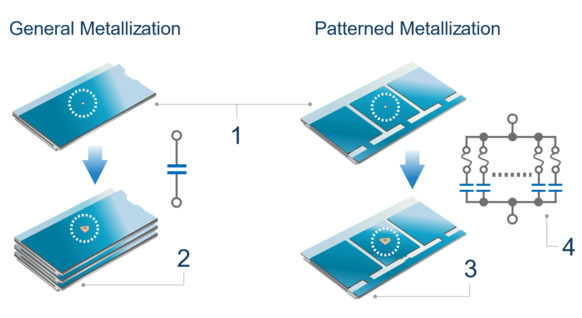

Comparison between general and patterned metallization:

- Small break down

- Short circuit mode with risk of smoking or burning out

- Fuse function isolates the failed cell, and finally leads to open circuit

- Failed cell is isolated

Panasonic’s In-house technology: Patterned metallized polypropylene film capacitors

On a very thin layer of vapor deposited aluminum, segments are made within capacitor’s dielectric material.

Those segments localize the failure caused by over voltage, therefore the damage is only limited in a few section of the capacitor.

When too many of the areas fail in a very short period of time, capacitor will then open in a safe manner.

A demonstration video is available for your to take a look (see below):

- We first apply high voltage to a dielectric material with Panasonic fuse pattern.

- Then we apply the same voltage to the raw material without fuse pattern.

- As you can easily recognize, the damage caused on non-fuse material is far more extensive than that of a fuse material.

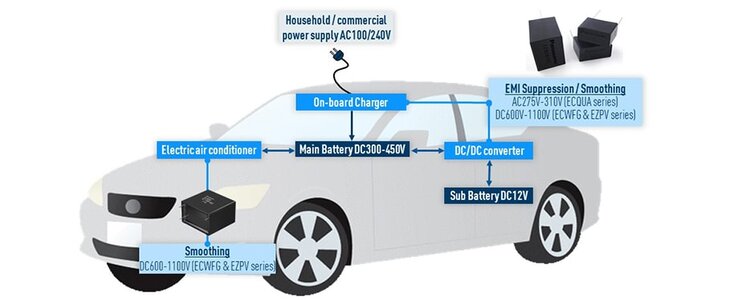

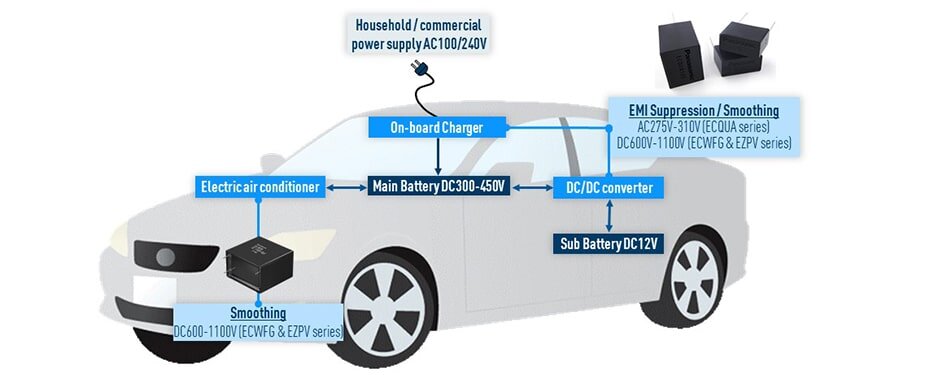

Thanks to this “Fuse Function” technology, Panasonic film capacitors are ideal solution for high-stress applications that require high safety and high reliability,

such as automotive applications (OBC, DC/DC converters, inverters for xEV etc.), industrial power supplies, solar inverters etc.

Safety testing data