Industries

Laser welding in practice

Successful manufacturing and welding of plastic parts requires particular attention towards different aspects from the very beginning. We will be happy to assist you in every stage of the project – from selecting suitable materials to designing and producing joining parts and finally when laser welding the plastic parts. During our consulting activities, we place great emphasis on the analysis of the material so that you will get optimum results. Panasonic offers a broad product portfolio for all production processes in your assembly.

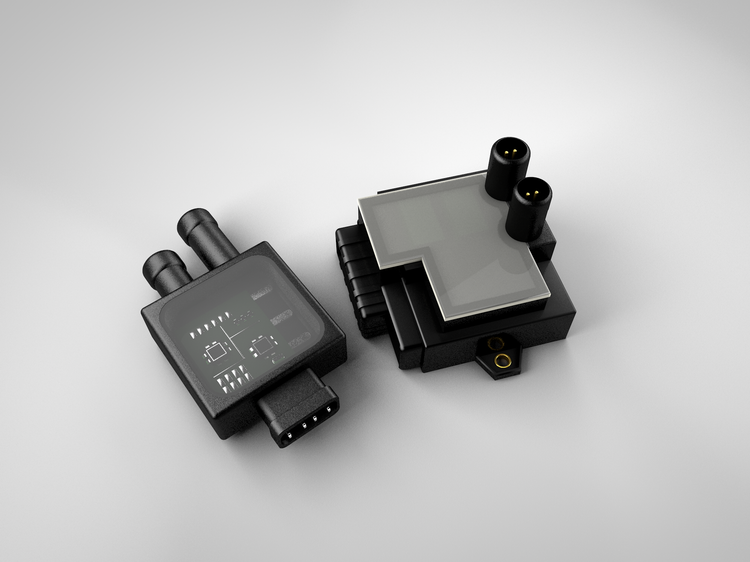

Automotive

In the automotive industry, it is vital to keep developing and improving vehicles. This is true in respect of performance, contaminant levels and consumption values as well as regarding the design. All these optimization tasks cannot be imagined without the innovative laser welding technique. The Panasonic laser welding systems are a reliable basis when it comes to designing and welding of plastic components in the automotive industry. They fulfill all necessary requirements.

Electronics

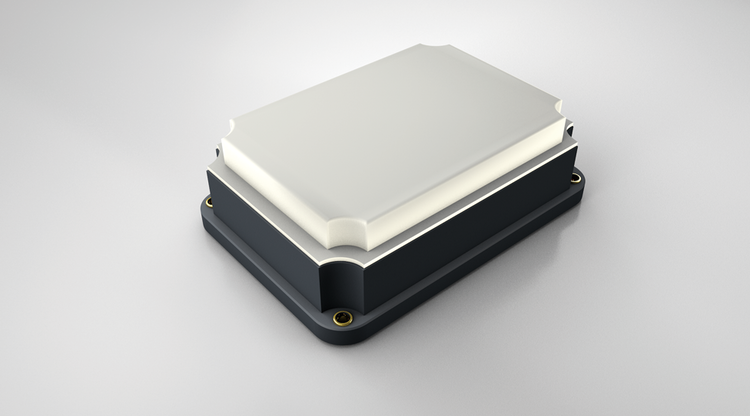

In the electrical industry, the variety of applications for laser welding systems is nearly unlimited, since plastic housings prove effective for the protection of sensitive electronic devices. The VL-W1 series offers a particle-free welding of joining parts and, compared with the friction welding method, increases productivity and reduces the reject rate.

Pharma

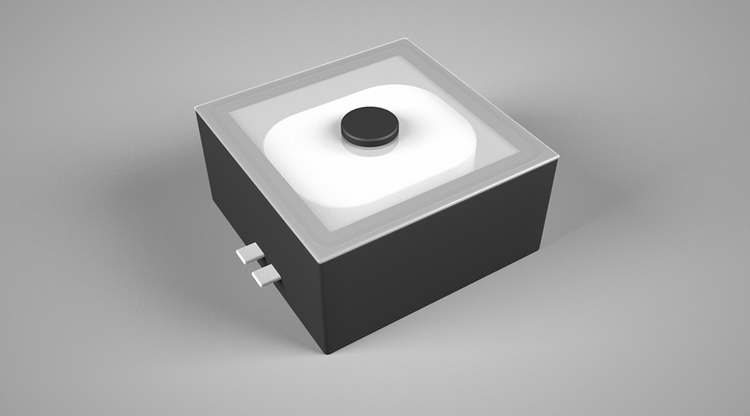

Lasers are an integral part of the medical technology industry. They enable much progress. This development trend is also supported by the innovative laser welding system VL-W1 for plastic components because it offers advantages unrivaled by any other bonding technology. Due to its unique welding technology, it effortlessly fulfills the high hygienic process standards of the medical technology industries.

Feasibility study

We take on every challenge. Before giving you with a product recommendation we will conduct a profound feasibility study. Depending on the specifications, we test the welding results for tensile strength and airtightness, and execute microscopy analyses.

Panasonic’s central European laboratory is manned by experienced, highly qualified experts who analyze which plastic parameters offer the optimum quality and weld strength for your particular application. We process every inquiry without delay.

Fill in the request form and send it together with your samples to:

Panasonic Industry Europe GmbH

Laser Marking and Processing Laboratory

Maria-Merian-Strasse 7

85521 Ottobrunn

Germany