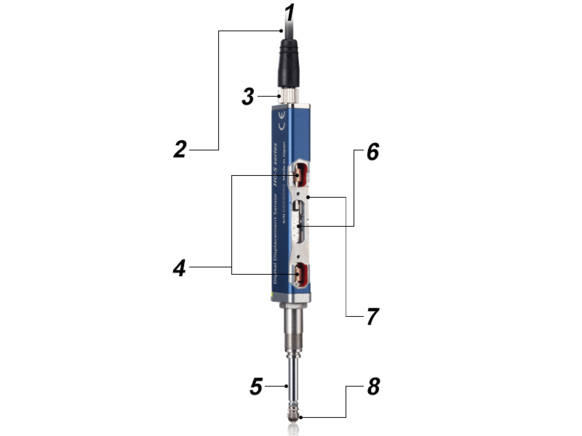

HG-S measurement sensor

Slim unit body

- Slim robust pencil-type sensor unit

- Bending-resistant cable even when used for moving parts

- Hot-swappable

- Plain bearings with 2-point support structure ensure excellent resistance to lateral loads

- Resistance to lateral load

- High accuracy: The high-precision sensor head has a resolution of 0.1µm and an indication accuracy of max. 1µm for the full range and max. 0.5µm for the narrow range. The high-resolution CMOS sensors measure the amount of movement by reading the glass scales that have different slit patterns at different read positions. This provides accurate measurements even in high-speed measuring operations. It also eliminates mechanical zero position runs when the system has been switched on.

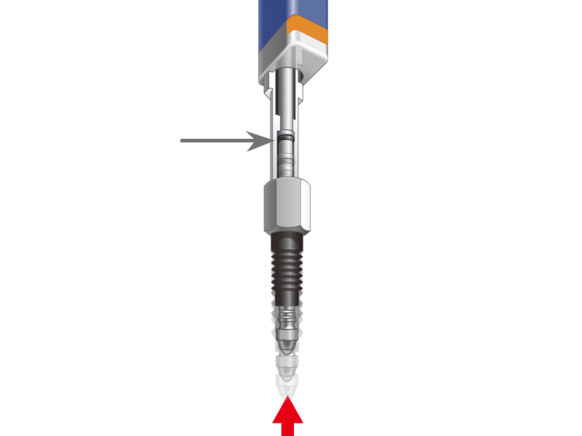

- Resistance to upward thrust impact: Even when a sudden upward thrust impact occurs, the resulting load is applied only to the lower section of the sensor unit. The spindle stopper minimizes the impact on the glass scales.

- Tip deviation amount of max. 35µm

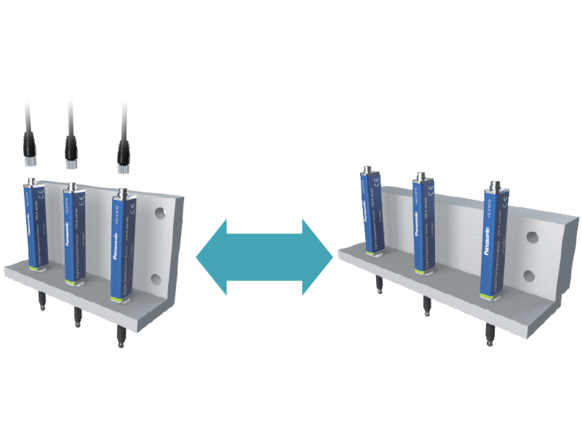

Hot-swappable

The sensor head can be changed safely without turning off the controller. This reduces the man-hours required for changing the line setup when different workpieces need to be processed.

Excellent workmanship

The two plain bearings are accurately aligned with the center of the spindle during their installation to the top and bottom sections of the body to ensure smooth sliding.

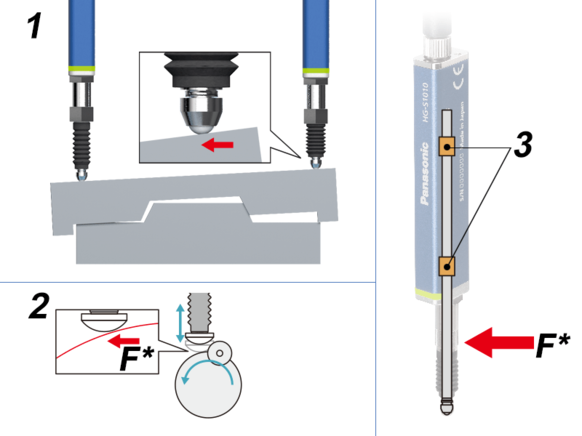

Resistance to lateral load

The two plain bearings are accurately aligned with the center of the spindle during their installation to the top and bottom sections of the body to ensure smooth sliding. The sensor can withstand more than 100 million sliding operations under application of lateral load (reference value).

- Lateral load is generated when the sensor is positioned at an angle or the workpiece becomes tilted.

- Lateral load resistance test: The sensor withstands 100 million sliding operations (reference value).

- The two plain bearings increase the resistance to mechanical stress from the side and ensure the accuracy of measuring results even under lateral load.

* F = Force

Resistance to upward thrust impact thanks to spindle stopper

Even when a sudden upward thrust impact occurs, the resulting load is applied only to the lower section of the sensor unit because a spindle stopper minimizes the impact on the glass scales.

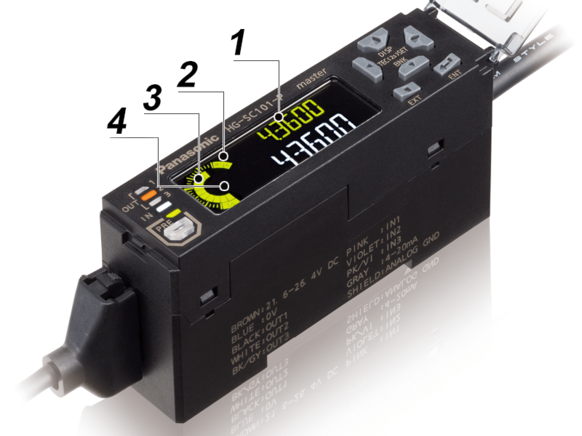

Versatile and easy-to-use controller

- Dual display for more flexibility

- All-direction LCD

- Intuitive circle meter

- Copy function from master to slave units

High-speed response of 3ms in combination with any sensor head

Useful maintenance mode for the production floor.

The following data are stored and can be used for analysis on the spot:

- Abnormal sensor head upward thrust value

- Number of sensor head upward thrusts

- Cumulative total number of sliding operations

Alarm for upward thrust

An alarm can be set to notify the user of an upward thrust (stroke) that exceeds the set level. This allows you to conduct a preventive maintenance before the sensor head generates a malfunction.

Easy-to-understand 2-line digital display

The 2-line digital display simultaneously shows head measurement (measured value) and judgment value (calculated value). The high-contrast LCD provides sharp and clear indications and offers a wide viewing angle.

- Secondary display line: Displays sensor head measurement and other data.

- Main display line: displays judgment value.

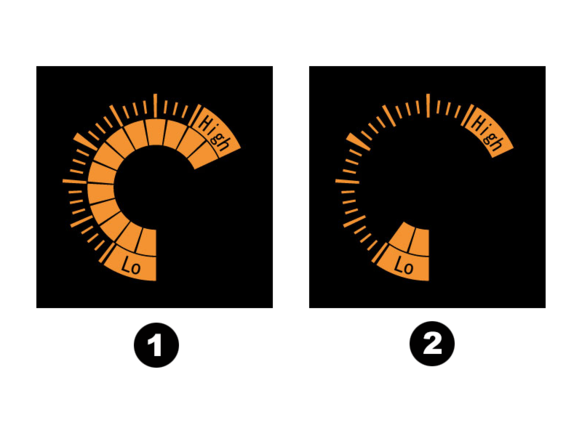

Intuitive circle meter

Values within the maximum and minimum limits are indicated in green. Values outside the valid range are indicated in orange. This allows users to check the margin to the limits at a glance.

- Higher than maximum value.

- Lower than minimum value

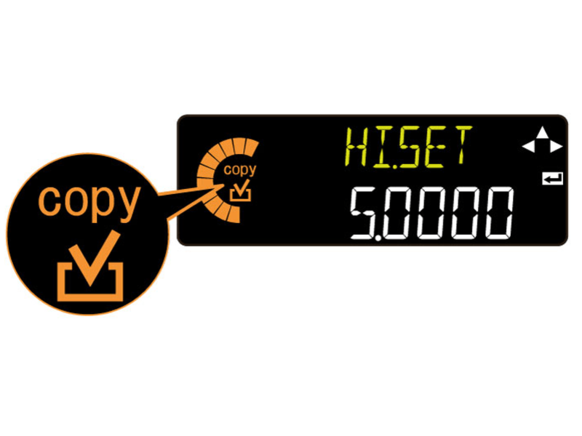

Copy function

During configuration of the master unit, the copy function symbol lights up for setting items that can be copied to slave units. This significantly reduces the man-hours required for configuration and maintenance.

Easy tolerance setting – simple 1-point teaching

Align with master workpiece and press ENTER for easy tolerance setting.

1. Master workpiece

2. Press once!

3. Tolerance setting completed!

4. Tolerance on positive side (HIGH set value)

5. Reference value

6. Tolerance on negative side (LOW set value)

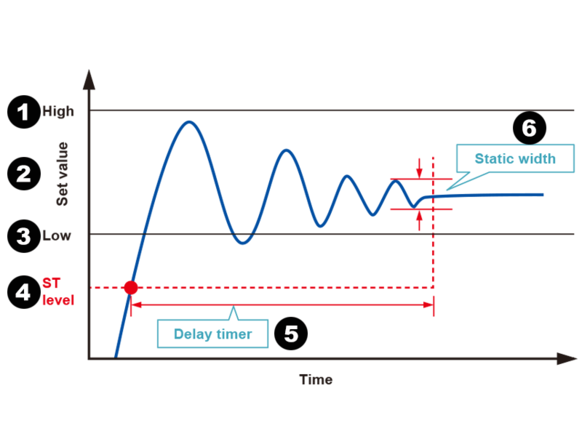

No need for trigger input thanks to self-trigger function

The measurement process does not need to be triggered externally. It starts automatically when either the fluctuation of measurement values has stabilized or with a specified time delay after the self-trigger level (ST level) has been reached

1. Static width setting

As soon the measurement curve is stable within the specified range, the measured value will be sent to the analog output.

2. Delay timer setting

When the measurement value has reached the ST level and the specified delay time has elapsed, the measured value will be sent to the analog output.

- High

- Set value

- Low

- Self-trigger level (ST level)

- Delay timer

- Static width

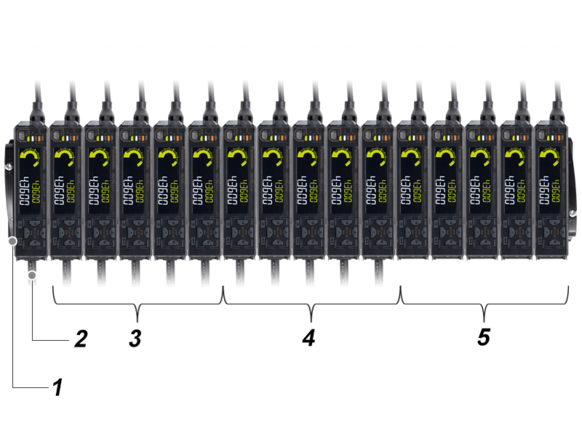

Serial connection of up to 15 slave units

One master unit can be connected in series with up to 15 slave units in any order. This allows easy multi-point calculations. End plates (optional) must be mounted on both sides of the controller after the connection of slave units.

Unit types

Master unit (1 type): High performance type (analog current + input / output)

Slave unit (3 types ):

- High performance type (analog current + input / output)

- Standard type (input / output)

- Wire-saving type

1. End plates MS-DIN-E

2. Master unit HG-SC101 (high-performance type with analog current + digital input / output)

3. Slave unit HG-SC111 (high-performance type with analog current + digital input / output)

4. Slave unit HG-SC112 (standard type with digital input / output)

5. Slave unit / HG-SC113 (wire-saving type)

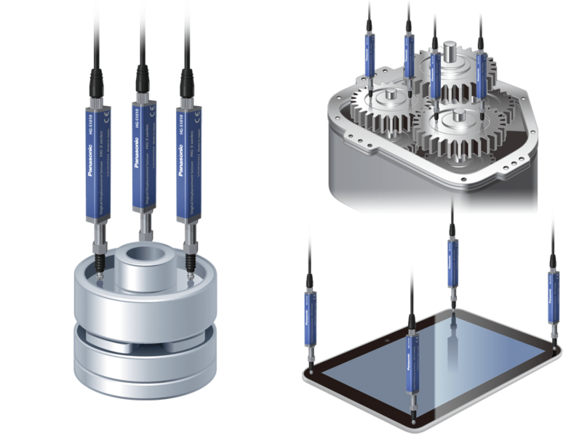

Applications

- Coupling assembly inspection

- Transmission parts height measurement

- Flat screen flatness measurement

Order guide - Sensor head

| Type | Resolution | Indication accuracy (P-P, full range) | Measurement range | Model No. | |

|---|---|---|---|---|---|

| General purpose | Standard type | 0.5μm | Max. 2.0μm | 10mm | HG-S1010 |

| Standard type | 0.5μm | Max 3.0μm | 32mm | HG-S1032 | |

| Standard type | 0.5μm | Max. 3.5μm | 50mm | HG-S1050 | |

| Low measuring force type (note 1) | 0.5μm | Max. 2.0μm | 10mm | HG-S1010R | |

| Air driven type | 0.5μm | Max. 2.0μm | 10mm | HG-S1010-AC | |

| High precision | Standard type | 0.1μm | Max. 1.0μm | 10mm | HG-S1110 |

| Low measuring force type (note 1) | 0.1μm | Max. 1.0μm | 10mm | HG-S1110R | |

| Air Driven type | 0.1μm | Max. 1.0μm | 10mm | HG-S1110-AC | |

Note 1: The low measuring force type is not equipped with rubber bellows.

Sensor head connection cable (bending-resistant type)

| Designation | Length | Model No. |

|---|---|---|

| Straight connector | 3m | CN-HS-C3 |

| 7m | CN-HS-C7 | |

| 10m | CN-HS-C10 | |

| 20m | CN-HS-C20 | |

| L-shaped connector | 3m | CN-HS-C3L |

| 7m | CN-HS-C7L | |

| 10m | CN-HS-C10L | |

| 20m | CN-HS-C20L |

Order guide - Controller

| Type | Output | Model No. | |

|---|---|---|---|

| Master unit | High-performance type (analog current + input / output) | NPN | HG-SC101 |

| PNP | HG-SC101-P | ||

| Slave units | High-performance type (analog current + input / output) | NPN | HG-SC111 |

| PNP | HG-SC111-P | ||

| Standard type (input / output) | NPN | HG-SC112 | |

| PNP | HG-SC112-P | ||

| Wire-saving type | - | HG-SC113 | |

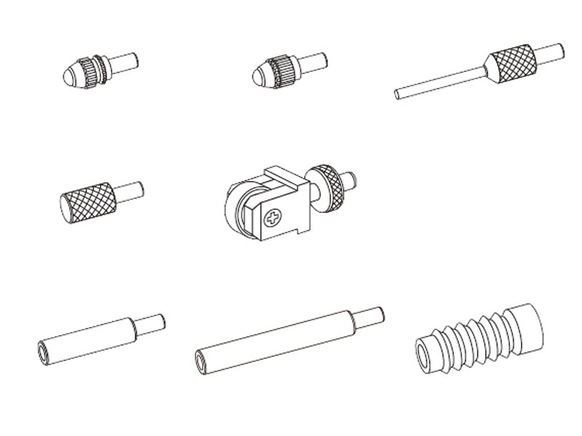

Options

| Designation | Model No. | |

|---|---|---|

| Probe | Standard type | TR-S10-Cx5 (5 pcs. per set) |

| Super-hard type | TR-S10-H | |

| Super-hard needle type | TR-S321-H | |

| Flat-seated type | TR-S411-K | |

| Roller type | TR-S601 | |

| Offset type | TR-S700-H | |

| Joint | Length 15mm type | TR-J102 |

| Length 25 mm type | TR-J104 | |

| Rubber bellows | TR-G20X5 (5 pcs. per set) | |

| TR-G50X5 | ||

Specifications - Air driven type

| Type | Air-driven type | ||

|---|---|---|---|

| General purpose | High precision | ||

| Model No. | HG-S1010-AC | HG-S1110-AC | |

| Compatible controller | HG-SC101(-P), HG-SC111(-P), HG-SC112(-P), HG-SC113 | ||

| Position detection method | Optical absolute linear encoder method | ||

| Measurement range | 10mm (note 1) | ||

| Stroke | Min. 10.5mm (note 1) | ||

| Measuring force | Downward mount | Dependent on applied air | |

| Upward mount | |||

| Side mount | |||

| Resolution | 0.5μm | ||

| Indication accuracy (P-P) | Full range: max. 2.0μm Narrow range: max. 1.0μm | ||

| Tip deviation amount | 35μm (typical) | ||

| Hot-swap function | Incorporated | ||

| Working pressure range | 0.14 to 0.16MPa 0.035 to 0.045MPa (without seal cap) | ||

| Capacity to resist pressure | 0.2MPa | ||

| Applicable fluid | Clean air | ||

| Applicable tube | Outside diameter: 4mm Inside diameter: 2.5mm | ||

| Operation indicator | 2-color LED (orange / green) | ||

| Environmental resistance | Protective structure | IP67 (IEC, note 2) | |

| Ambient temperature | Operation: -10 to +55°C (no condensation or ice) Storage: -20 to +60°C | ||

| Ambient humidity | 35 to 85% RH, storage: 35 to 85% RH | ||

| Insulation resistance | Min. 100MΩ at 250V DC | ||

| Vibration resistance | 10 to 500Hz frequency, 3mm double amplitude (maximum acceleration 196m/s2) in X, Y and Z directions for two hours each | ||

| Shock resistance | 1960m/s2 acceleration in X, Y and Z directions three times each | ||

| Material | Body: zinc, holder: stainless steel, spindle: tool steel, probe (see options): ceramic, air-tube clamp: S60CM | ||

| Weight | Net weight: approx. 80g | ||

| Accessories | Sensor head fastening wrench 1 pc., mounting nut 1 pc., seal cap 1 pc., air-tube clamp 1 pc. | ||

Notes:

- Measured at an ambient temperature of +20°C

- The seal cap has to be applied.

Specifications - Sensor head

| Type | General purpose | High precision | |||

|---|---|---|---|---|---|

| Standard type | Low measuring force type | Standard type | Low measuring force type | ||

| Model No. | HG-S1010 | HG-S1010R | HG-S1110 | HG-S1110R | |

| Compatible controller | HG-SC101(-P), HG-SC111(-P), HG-SC112(-P), HG-SC113 | ||||

| Position detection method | Optical absolute linear encoder method | ||||

| Measurement range | 10mm (note 1) | ||||

| Stroke | Min. 10.5mm (note 1) | ||||

| Measuring force (note 2, note 3) | Downward mount | Max. 1.65N 1.1N (note 4) | Max. 0.35N 0.3N (note 4) | Max. 1.65N 1.1N (note 4) | Max. 0.35N 0.3N (note 4) |

| Upward mount | Max. 1.35N 0.85N (note 4) | Max. 0.12N 0.05N (note 4) | Max. 1.35N 0.85N (note 4) | Max. 0.12N 0.05N (note 4) | |

| Side mount | Max. 1.5 N 0.95N (note 4) | Max. 0.25N 0.2N (note 4) | Max. 1.5N 0.95N (note 4) | Max. 0.25N 0.2N (note 4) | |

| Resolution | 0.5μm | 0.1μm | |||

| Indication accuracy (P-P) (note 2) | Full range: max. 2.0μm Narrow range: max. 1.0μm (any 60μm) | Full range: max. 1.0μm Narrow range: max. 0.5μm (any 60μm) | |||

| Tip deviation amount | 35μm (typical) | ||||

| Hot-swap function | Incorporated | ||||

| Operation indicator | 2-color LED (orange / green) | ||||

| Environmental resistance | Protective structure | IP67 (IEC, note 5) | - | IP67 (IEC, note 5) | - |

| Ambient temperature | Operation: -10 to +55°C (no condensation or ice) Storage: -20 to +60°C | ||||

| Ambient humidity | 35 to 85% RH, storage: 35 to 85% RH | ||||

| Insulation resistance | Min. 100MΩ at 250V DC | ||||

| Vibration resistance | 10 to 500Hz frequency, 3mm double amplitude (maximum acceleration 196m/s²) in X, Y and Z directions for two hours each | ||||

| Shock resistance | 1960m/s² acceleration in X, Y and Z directions three times each | ||||

| Mechanical life | Min. 100 million times (note 6) | ||||

| Tightening torque | Set screw: 1.5N m, nut: 12.5N m | ||||

| Probe tightening torque | 0.1 to 0.4N m (no force applied to main unit) | ||||

| Grounding method | Capacitor grounding | ||||

| Material | Body: zinc, holder: stainless steel, spindle: tool steel, probe (note 7): ceramic, rubber bellows: NBR (black) | ||||

| Weight | Net weight: approx.. 80g | ||||

| Accessories | Standard type (HG-S1010 / HG-S1110): Sensor head fastening wrench 1 pc., mounting nut 1 pc Low measuring force type (HG-S1010R / HG-S1110R): Sensor head fastening wrench 1 pc., mounting nut 1 pc., rubber bellows 1 pc. | ||||

Notes:

1. 5 to 10mm range when low measurement force type (HG-S1010R / HG-S1110R) is mounted in upward mount. 2. Measured at an ambient temperature of +20°C

3. In the case of low measuring force type (HG-S1010R / HG-S1110R), measurements were obtained with products in standard configuration without rubber bellows.

4. Typical value near center of measurement.

5. Excludes damage and deterioration to rubber bellows due to external causes.

6. Typical value in a clean environment with no contact with dust or liquids such as water and oil. Four million times (typical) when low measurement force type (HG-S1010R / HG-S1110R) is mounted in upward mount.

7. Different probes (optional) are also available.

Specifications - Controller

| Type | Master unit | Slave unit | |||

|---|---|---|---|---|---|

| High-performance type | High-performance type | Standard type | Wire-saving type | ||

| Model No. | NPN output | HG-SC101 | HG-SC111 | HG-SC112 | HG-SC113 |

| PNP output | HG-SC101-P | HG-SC111-P | HG-SC112-P | ||

| Compatible sensor head | HG-S1010(R), HG-S1110(R) | ||||

| Number of connectable units | Up to 15 slave units can be connected per master unit. | ||||

| Supply voltage | 24V DC ±10%, including ripple 0.5V (P-P) | ||||

| Current consumption (note 2) | Max. 70mA (when sensor head is connected) | ||||

| Analog current output (note 3) |

|

– | |||

| Control output (output 1, output 2, output 3) | NPN output type

PNP output type

|

– | |||

| Short-circuit protection | Incorporated (automatic reset type) | – | |||

| Judgment output | NO / NC switching method | – | |||

| Alarm output | Open when alarm occurs | – | |||

| External input (input 1, input 2, input 3) | NPN output type

PNP output type

|

– | |||

| Trigger input | Input time min. 2ms (ON) | – | |||

| Preset input | Input time min. 20ms (ON) | – | |||

| Reset input | Input time min. 20ms (ON) | – | |||

| Bank input A / B | Input time min 20ms (ON) | – | |||

| Response time | 3ms, 5ms, 10ms, 100ms, 500ms, 1,000ms switching type | ||||

| Digital display | 204-segment LCD | ||||

| Display resolution | 0.1μm | ||||

| Display range | -199.9999 to 199.9999mm | ||||

| Contamination level | 2 | ||||

| Altitude | Max. 2000m | ||||

| Environmental resistance | Degree of protection | IP40 (IEC) | |||

| Ambient temperature | -10 to +50°C (no condensation or ice), storage: -20 to +60°C | ||||

| Ambient humidity | 35 to 85% RH, storage: 35 to 85% RH | ||||

| Insulation resistance | Min. 20MΩ, with 250V DC megger between all supply terminals connected together and enclosure | ||||

| Withstand voltage | 1000V AC for one minute between all supply terminals connected together and enclosure | ||||

| Vibration resistance | 10 to 150Hz frequency, 0.75mm amplitude in X, Y and Z directions for two hours each | ||||

| Shock resistance | 98m/s² acceleration (10G approx.) in X, Y and Z directions five times each | ||||

| Material | Case: polycarbonate, cover: polycarbonate, switches: polyacetal | ||||

| Cable | 0.2mm² 2-core cable (brown and blue lead wires) / 0.15mm² 7-core composite cable, 2m long | 0.15mm², 7-core composite cable, 2m long | 0.15mm², 6-core cab tire cable, 2m long | – | |

| Weight (approx.) | 140g | 140g | 130g | 60g | |

Notes:

1. Where measurement conditions have not been specified precisely, the conditions used were as follows: supply voltage 24V DC, ambient temperature +20°C.

2. Current consumption does not include analog current output.

3. Linearity F.S. = 16 mA, and is linearity with respect to digitally measured values.

4. When slave units are connected to the master unit, the maximum sink current / source current of the control output and ambient temperature vary depending on the number of connected slave units as shown below.

| Number of connected slave units | Maximum sink current / source current of control output | Ambient temperature |

|---|---|---|

| 1 to 7 slave units | 20mA | -10 to +45°C |

| 8 to 15 slave units | 10mA |

HG-S communication unit

Direct transfer of high-precision measurement values: new communication unit for the HG-S series

The new RS485 communication unit for the HG-S sensor series is used to transfer high-precision measurement values directly, making data traceability easier than before. Communication does not only work for measurement values, but also for parameters, making it easy to manage inspection results and identify causes in the event of a failure.

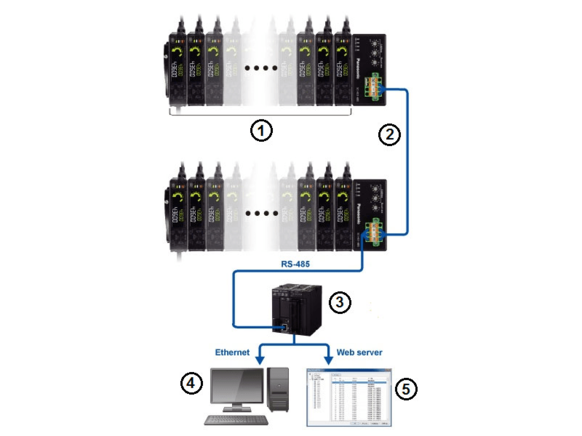

Installation example

In a network installation, a PLC and a computer can be used to control a number of stations remotely. Each station consists of a master, up to 14 slaves, and the SC-HG1-485 communication unit. The maximum number of stations is limited by the communication protocol selected: 99 stations for MODBUS (RTU/ASCII) and 64 stations for MEWTOCOL-COM.

- Station consisting of a master sensor, up to 14 slave sensors, and the SC-HG1-485 communication unit

- Two protocols available:

- MODBUS (RTU/ASCII) for connection of up to 99 stations

- MEWTOCOL-COM for connection of up to 64 stations - Programmable controller FP7 series

- PC for analysis and cause investigation

- Web server for data logging

Order guide

| Product name | Model No. | Description |

|---|---|---|

| RS485 communication unit | SC-HG1-485 | Communication unit for RS485 communication. Two protocols available:

|

Specifications HG-S communication unit

| Product name | RS485 communication unit for measurement sensors | |

|---|---|---|

| Model No. | SC-HG1-485 | |

| Applicable standards | EMC directive | |

| Compatible controller | HG-SC | |

| Supply voltage | 24V DC ±10% including ripple max. 10% (P-P) (within specified power supply voltage range) Note: The power is supplied from the master sensor. | |

| Current consumption | Max. 40mA | |

| Communication method | Two-wire half-duplex communication | |

| Synchronization method | Start-stop synchronization | |

| Communication protocol | MODBUS (RTU, ASCII), MEWTOCOL-COM | |

| Communication speed | 1.2 kbit/s, 2.4 kbit/s, 4.8 kbit/s, 9.6 kbit/s, 19.2 kbit/s, 38.4 kbit/s, 57.6 kbit/s, 115.2 kbit/s | |

| Electrical characteristics | Complies with EIA RS-485 | |

| Number of stations connectable to a host | 1 to 99 units when MODBUS (RTU/ASCII) is used 1 to 64 units when MEWTOCOL-COM is used | |

| Number of connectable sensors per station | Maximum of 15 sensors (1 master, 14 slaves) per SC-HG1-485 unit | |

| Stop bit length | 1 bit, 2 bits | |

| Parity check | None, even, odd | |

| Data length | 8 bits (RTU), 7 bits (ASCII) | |

| Pollution degree | 2 | |

| Operating altitude | Max. 2000m | |

| Environmental resistance | Degree of protection | IP40 (IEC) |

| Ambient temperature | -10 to +45°C (no condensation or ice), storage: -20 to +60°C | |

| Ambient humidity | Operation and storage: 35 to 85% RH | |

| Insulation resistance | Min. 20MΩ, with 250V DC megger between all supply terminals connected together and enclosure | |

| Withstand voltage | 1000V AC for one minute between all supply terminals connected together and enclosure | |

| Vibration resistance | 10 to 150Hz frequency, 0.75mm amplitude in X, Y and Z directions for two hours each | |

| Shock resistance | 98m/s² acceleration (10G approx.) in X, Y and Z directions five times each | |

| Material | Case: polycarbonate | |

| Maximum length for communication cable | Max. 1200m between SC-HG1-485 (terminal) and PLC | |

| Weight (approx.) | Net weight: 75g, gross weight: 120g. | |

| Accessories | Termination resistor switching jumper: 1 pc. | |

Downloads

| Name | Size | Date | Language |

|---|---|---|---|

| HG-S Controller 3D Data | 457 KB | 26.07.2023 | Other |

| HG-S Controller 2D Data | 55 KB | 26.07.2023 | Other |

| HG-S Head 3D Data | 621 KB | 26.07.2023 | Other |

| HG-S Head 2D Data | 56 KB | 26.07.2023 | Other |

| HG-S Probe 2D Data | 27 KB | 26.07.2023 | Other |

| HG-S Probe 3D Data | 93 KB | 26.07.2023 | Other |

| SC-HG1-ETC 2D data | 15 KB | 26.07.2023 | Other |

| SC-HG1-ETC 3D data | 824 KB | 26.07.2023 | Other |

| Name | Size | Date | Language |

|---|---|---|---|

| Selection guide measurement sensors | 10 MB | 23.03.2022 | English |

| Sensor Selection Guide for Packaging Industry | 15 MB | 12.07.2022 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Digital Displacement Sensor Head HG-S. Air-Driven Type Digital Displacement Sensor Heads Featuring Slim Body! | 2 MB | 23.03.2022 | English |

| Catálogo Resumen Sensores | 29 MB | 28.03.2024 | Spanish |

| Raccolta Applicazioni Sensori | 24 KB | 08.04.2025 | Italian |

| Name | Size | Date | Language |

|---|---|---|---|

| HG-S series: Digital Displacement Sensor | 2 MB | 23.03.2022 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| HG-S Series User's Manual, WUME-HGS-12 | 13 MB | 12.06.2024 | English |

| HG-SC Instruction Manual, MJE-HGSC | 2 MB | 09.04.2024 | English |

| HG-S Contact-Type Digital Displacement Sensor/Head, MJE-HGS1010 | 389 KB | 27.11.2024 | English |

| SC-HG1-485 User's Manual, WUME-SCHG1485-6 | 4 MB | 12.06.2024 | English |

| SC-HG1-C User’s Manual, WUME-SCHG1C-6 | 4 MB | 12.06.2024 | English |

| SC-HG1-ETC EtherCAT communication Instruction Manual, MJE-SCHG1ETC | 2 MB | 30.10.2024 | English,Japanese |

| SC-HG1 USB Communication Unit Instruction Manual, CMJE-SCHG1USB | 2 MB | 30.10.2024 | English,Japanese |

| SC-HG1-ETC EtherCAT communication User’s Manual, WUME-SCHG1ETC-4 | 3 MB | 12.06.2024 | English |

| HG-S-AC Instruction Manual, MJE-HGSAC | 1 MB | 09.04.2024 | English |

| SC-HG1-CEF Instruction Manual , MJE-SCHG1CEF | 2 MB | 28.10.2024 | English,Japanese |

| SC-HG1-C Instruction Manual, MJE-SCHG1C | 2 MB | 28.10.2024 | English |

| SC-HG1-485 Instruction Manual, MJE-SCHG1485 | 2 MB | 28.10.2024 | English,Japanese |

| SC-HG1-CEF User’s Manual , WUME-SCHG1CEF-6 | 3 MB | 12.06.2024 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| HG-S series: Slim & Robust Sensor Unit | 8 MB | 23.03.2022 | English |

| Brochure Capteurs | 32 MB | 28.03.2024 | French |

| Senzory - Zkrácená verze | 10 MB | 28.03.2024 | Czech |

| Übersicht Sensoren | 28 MB | 28.03.2024 | German |

| Short Form Sensors for Factory Automation | 33 MB | 28.03.2024 | English |

| Programma Sensori | 3 MB | 28.03.2024 | Italian |

| Übersicht Topseller Automatisierungstechnik, 6215eude | 3 MB | 02.05.2024 | German |

| Top seller - Automation products, 6215euen | 3 MB | 01.05.2024 | English |

| Les essentiels - Produits d’automatisme, 6215eufr | 5 MB | 16.06.2023 | French |

| Catálogo resumen - Gama de producto automatización industrial | 6 MB | 25.09.2023 | Spanish |

| Brochure "Focus Automazione" | 8 MB | 08.01.2025 | Italian |

| Name | Size | Date | Language |

|---|---|---|---|

| SC-HG1-ETC(HG-S and HG-T), ESI file (EtherCAT definition file) | 219 KB | 23.04.2024 | English |