HG-C1000L measurement sensor with IO-Link

Transmission of sensor data via IO-Link

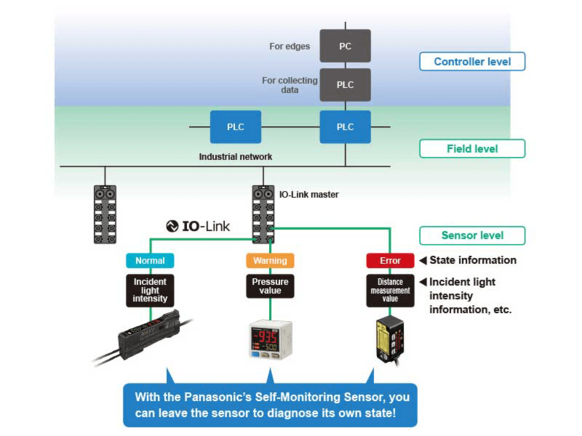

The IO-Link technology makes it possible to continuously collect and process data and to control the sensor. This allows users to implement predictive maintenance and to monitor operation in machines and assembly lines. Processing the multitude of data requires users to invest know-how and time. To reduce the workload for the customers, Panasonic has developed a self-diagnosis function specifically for this sensor. This function sends sensor data via IO-Link to a higher-level fieldbus, thus informing about the state of the sensor directly. This way, the amount of production data and the work needed to analyse the data is reduced.

A step towards Industry 4.0

To ensure smooth operation on the production floor, it is important to keep the machine downtime to a minimum. The new IO-Link technology permanently generates data on the sensor level and transmits them to a PLC for processing. The result is a large amount of data waiting to be analysed so that they can be used in a meaningful way. The right information helps to take effective measure in the case of a failure in the shortest possible time. To find out at an early stage why a component has failed is a big advantage. Panasonic’s IO-Link sensors are equipped with a self-diagnosis function which outputs individual failure information for each sensor type, for example when the amount of light received has deteriorated. This way, you receive error messages specifically for the problem at hand without extra programming effort.

Thanks to predictive systems, Industry 4.0 helps to reduce maintenance time. For sensors with a self-diagnosis function, users only need to monitor the parameter value that informs about whether the sensor is still working properly.

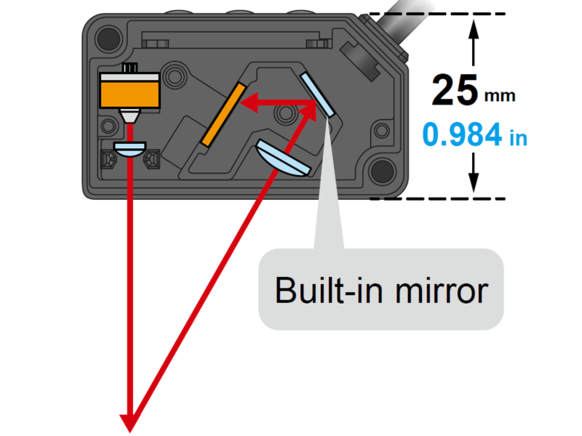

Compact miniaturized housing

Because the laser beam is deflected inside the sensor, it has been possible to reduce the housing to a minimum size. Parameters can be set directly at the device with the help of the buttons and the built-in display.

Easy configuration

Perform 1-point teaching and the threshold range is set for the distance from the reference surface of the object to be detected.

2-point-teaching uses threshold values. For this method, all you need to do is press TEACH once for the lower (first point) and once for the upper limit (second point). This is useful for detecting objects at different distances.

For the 3-point method, you set the threshold range by conducting the teaching at 3 points (detecting object A, B and C). After teaching, the reference points are automatically sorted in ascending order (reference point 1, 2 and 3). The thresholds are set at the midpoints between reference point 1 and 2, and 2 and 3, respectively. This is useful for detecting objects at different distances.

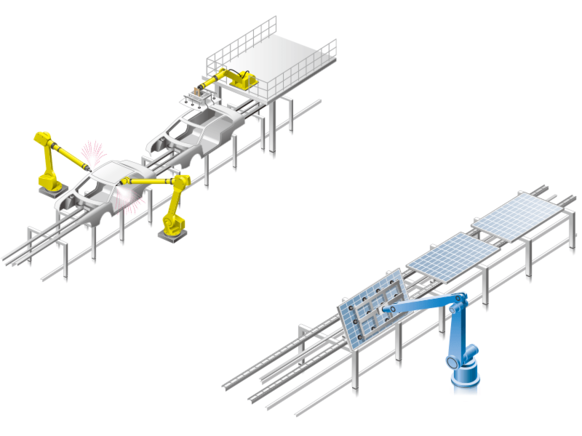

Applications

- Assembly line downtime caused by failures of the sensor can be avoided thanks to predictive maintenance.

-

When the sensor is mounted close to the assembly line it is often very difficult to change the device settings via the buttons because access to the sensor is very limited. Remote setup and monitoring of the sensor offers many advantages.

Downloads

| Name | Size | Date | Language |

|---|---|---|---|

| HG-C1000L 3D Data | 362 KB | 26.07.2023 | Other |

| HG-C1000L 2D Data | 24 KB | 26.07.2023 | Other |

| Name | Size | Date | Language |

|---|---|---|---|

| Catalogue IO-Link | 8 MB | 08.04.2025 | English |

| Sensor Selection Guide for Packaging Industry | 15 MB | 12.07.2022 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Catálogo Resumen Sensores | 29 MB | 28.03.2024 | Spanish |

| Raccolta Applicazioni Sensori | 24 KB | 08.04.2025 | Italian |

| Name | Size | Date | Language |

|---|---|---|---|

| Übersicht IO-Link Sensoren | 2 MB | 23.03.2022 | German |

| Overview IO-Link Sensors | 4 MB | 23.03.2022 | English |

| Resumen Sensores IO-Link | 4 MB | 23.03.2022 | Spanish |

| Name | Size | Date | Language |

|---|---|---|---|

| HG-C1000L Index list, MJE-HGCINDEX | 845 KB | 09.04.2024 | English |

| HG-C1000L Bedienungsanleitung, IMJE-HGCINDEXV1EN | 3 MB | 23.03.2022 | German |

| HG-C1000L Instruction Manual, ME-HGC1000L | 2 MB | 23.06.2025 | English |

| SC-LG2-CEF-P User's Manual, WUME-SCLG2CEFP-3 | 3 MB | 12.06.2024 | English |

| SC-LG2-CEF-P Instruction Manual, MJE-SCLG2CEFP | 803 KB | 28.10.2024 | English,Japanese |

| SC-LG-CEF Configuration Tool User's Manual, WUME-SCLGCT-4 | 3 MB | 10.04.2024 | English |

| Name | Size | Date | Language |

|---|---|---|---|

| Brochure Capteurs | 32 MB | 28.03.2024 | French |

| Senzory - Zkrácená verze | 10 MB | 28.03.2024 | Czech |

| Übersicht Sensoren | 28 MB | 28.03.2024 | German |

| Short Form Sensors for Factory Automation | 33 MB | 28.03.2024 | English |

| Programma Sensori | 3 MB | 28.03.2024 | Italian |

| Übersicht Topseller Automatisierungstechnik, 6215eude | 3 MB | 02.05.2024 | German |

| Top seller - Automation products, 6215euen | 3 MB | 01.05.2024 | English |

| Les essentiels - Produits d’automatisme, 6215eufr | 5 MB | 16.06.2023 | French |

| Catálogo resumen - Gama de producto automatización industrial | 6 MB | 25.09.2023 | Spanish |

| Name | Size | Date | Language |

|---|---|---|---|

| HG-C1000L, IODD file (IO-Link definition file) | 291 KB | 23.04.2024 | English |