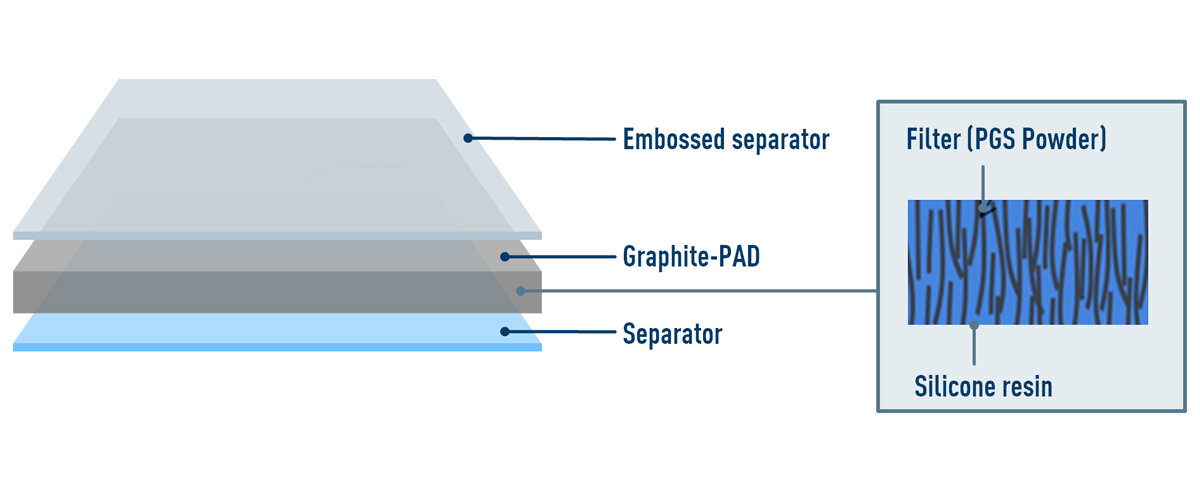

Features and structure of the Graphite-PAD

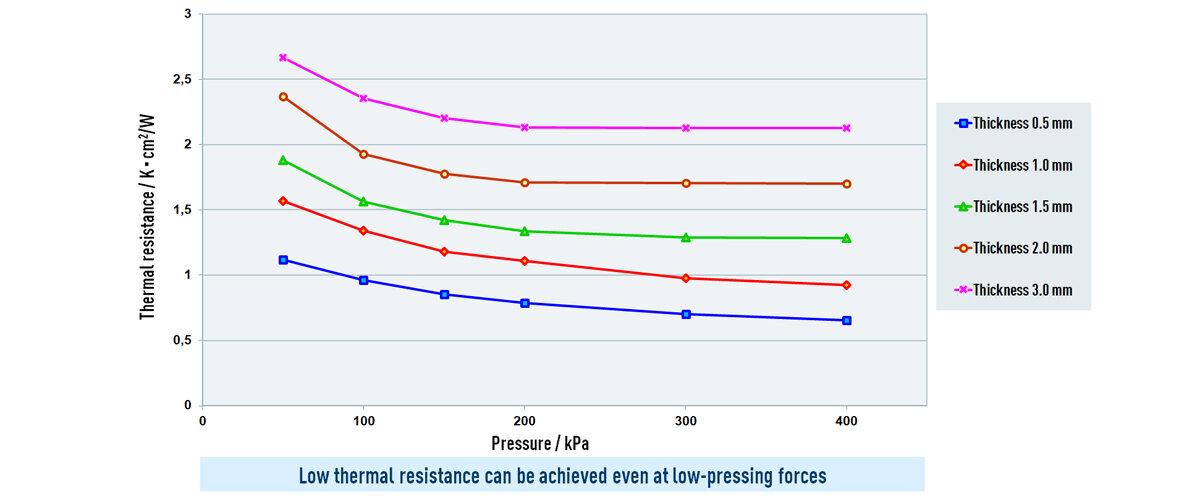

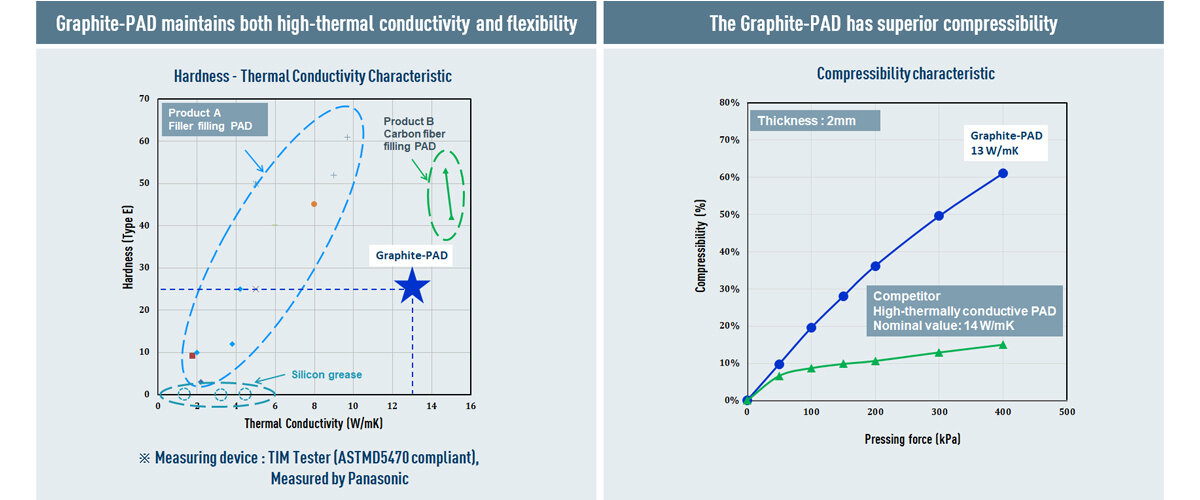

- Graphite-PAD is a high-performance Thermal Interface Material (TIM), with the best thermal conductivity and compressibility in thermal PAD market.

- High thermal conductivity out-of-plane (Z-axis) of 13 W/mK by vertical-oriented graphite powder filled in the silicon resin.

- Low Shore hardness (type E) of 25 and high compressibility of >60% supporting the flexibility of thermal design.

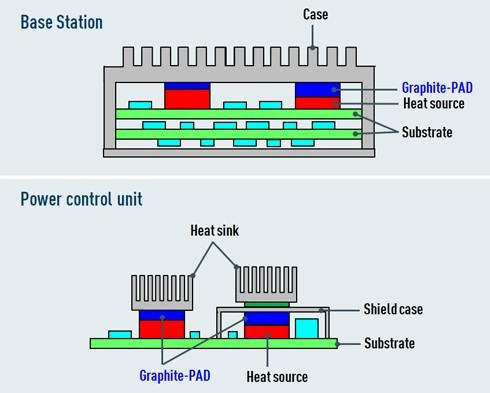

Specific usage example

Excellent flexibility for designing.

Examples:

- Base station

- Power control unit

Characteristics

| Characteristics | Unit | Test method / condition | Target value |

| Hardness | Type E | ASTM D2240 | 25 |

| Volume Resistance*1 | Ω・cm | 4 X 105 | |

| Thermal Conductivity*2 | W/mK | ASTM D5470, 50kPa | 13 |

| Application Temp. Range | °C | -40 to + 150 | |

| Thickness | mm | 0.5,1.0,1.5,2.0,2.5,3.0 |

*1 Graphite TIM is an electrically conductive material.

The component should only be applied to place where no electrical insulation is needed.

*2 Measuring device: TIM Tester (ANALYSIS TECH, ASTMD5470 compliant)

Please refer to our product catalog for detail specifications.

Product benchmark

Downloads

| Name | Size | Date | Language |

|---|---|---|---|

| Product catalog (Thermal Management Solutions) | 4 MB | 11.02.2026 | English |

Catalog

| Name | Size | Date | Language |

|---|---|---|---|

| Devices & Solutions catalogue | 12 MB | 02.09.2025 | English |

Data sheet

| Name | Size | Date | Language |

|---|---|---|---|

| Datasheet (Thermal conductive sheet PGS Graphite Sheet(GraphiteTIM)) | 529 KB | 09.06.2024 | English |

Packaging information

| Name | Size | Date | Language |

|---|---|---|---|

| Production location | 196 KB | 14.05.2025 | English |

Safety information

| Name | Size | Date | Language |

|---|---|---|---|

| Safety Precautions(Graphite-PAD) | 223 KB | 08.11.2023 | English |