Back-end processing: turning wafers into functional chips

From wafer to semiconductor: the back-end process transforms circuits into components ready for applications. Each step demands technologies that handle high-speed operation while maintaining micron-level precision. Discover how our solutions help you along the way.

Technology for semicon excellence

Your back-end equipment faces constant market pressure: smaller components, faster cycle times and flawless results. Our specialized components support semiconductor manufacturers seeking optimal performance.

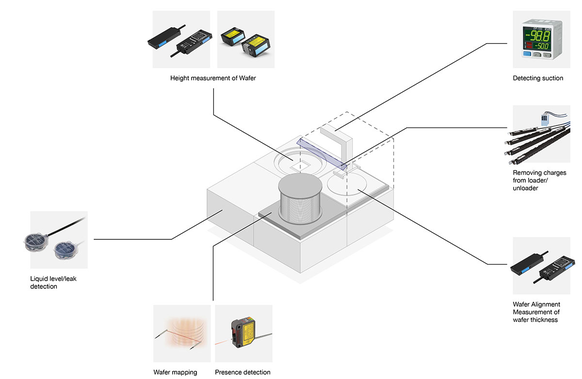

Probing

Automated machines test each die’s electrical properties. Only functional ones move forward.

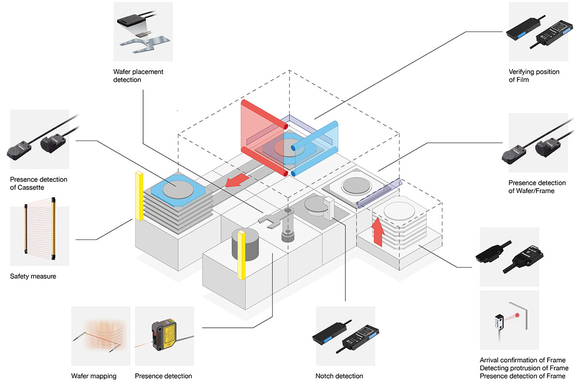

Die bonding

A robotic arm places each die onto a substrate. A crucial step in building the final package.

Wire bonding

Marking

From design to reality

The back-end process turns designs into components powering devices from smartphones to cars. With decades of experience, our solutions ensure speed, precision and reliability – just like they do for the front-end process.