Die bonding: accurate attachment for reliable packaging

Creating robust semiconductor packages requires accurate placement of individual dies onto substrates or leadframes. Therefore, make sure your die bonding process provides full capability and reliability. We've got the sensor technology to ensure precise alignment and stable handling.

Precision handling for die placement

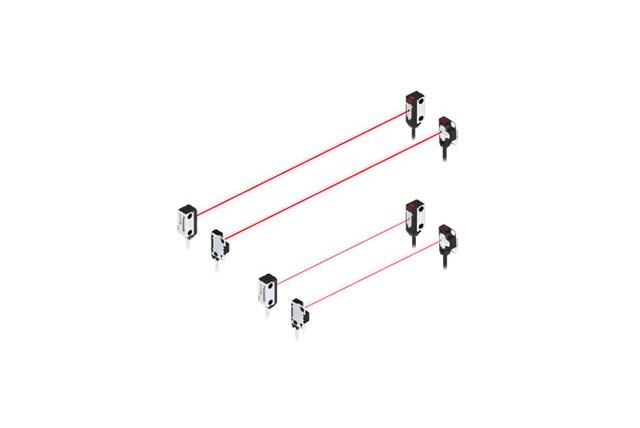

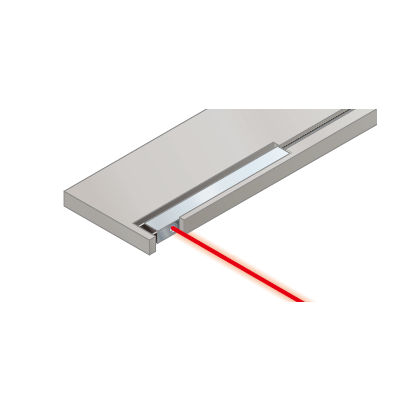

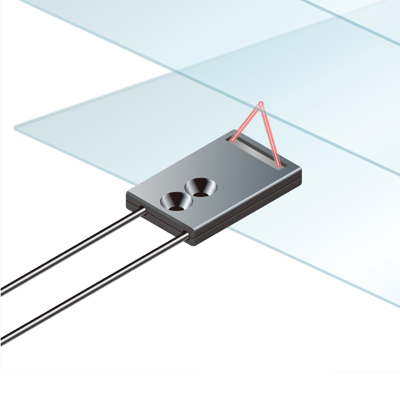

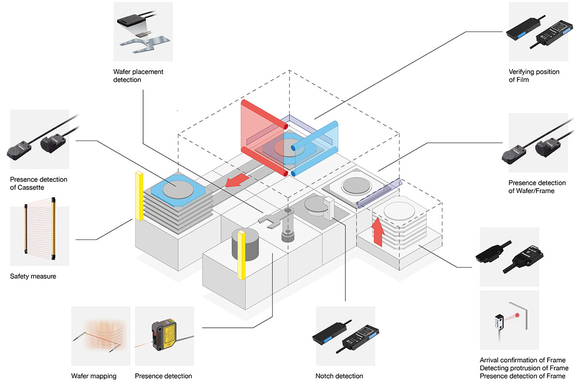

Die bonding systems require precise wafer detection, accurate film positioning and reliable frame alignment for secure die transfer. Optimize your equipment with our sensors for cassette presence detection, wafer placement verification and notch alignment. Monitor frame arrival and detect any misalignment issues, while our safety systems maintain operational integrity throughout the die bonding process.

Components for advanced bonding requirements

Modern packaging demands support a variety of bonding methods, including adhesive and thermocompression die bonding. Each technique requires exact die placement to ensure electrical paths and mechanical fixation in applications such as power devices, multi-die modules and RF components. Our components adapt to these needs, delivering the detection and monitoring required for consistent, high-yield assembly.