Front-end processing: from cleaning to conductivity

The front-end process for semiconductors occurs under special circumstances. Extreme temperatures, aggressive chemicals, and specific vacuum environments set the highest demands. Therefore, get to know solutions and products that reach beyond the standard.

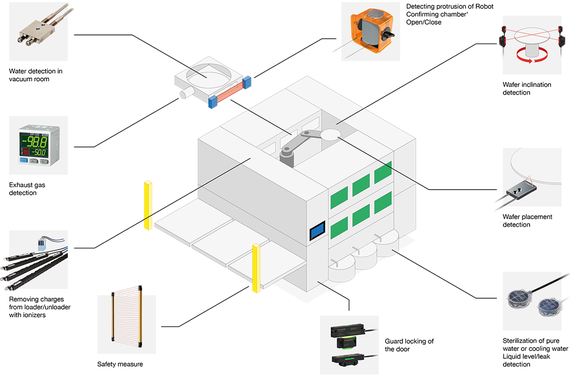

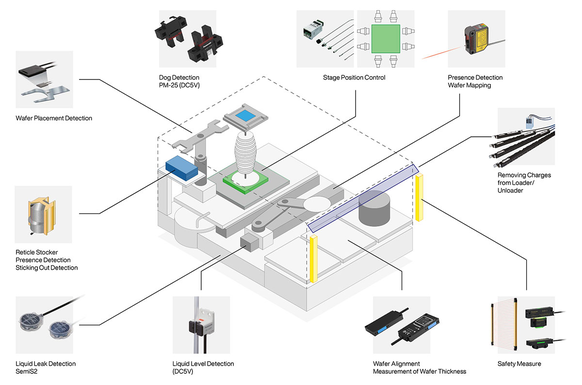

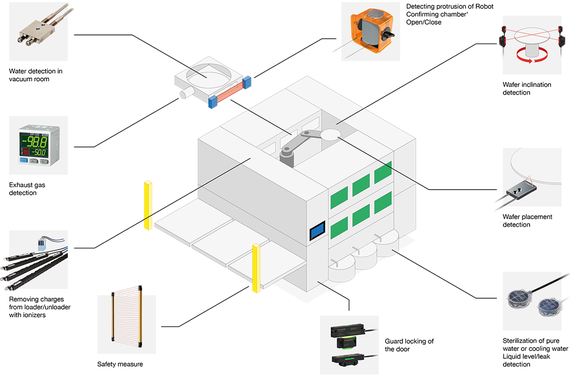

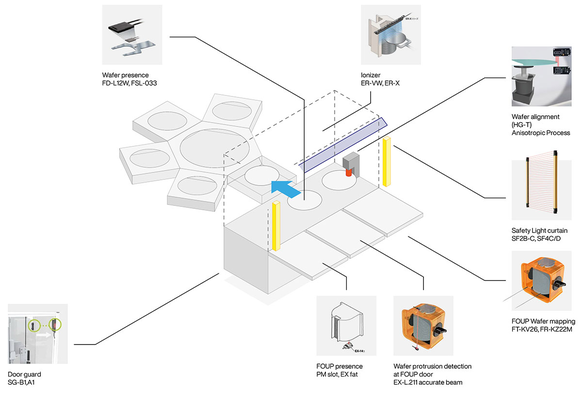

Made for your machines

The technology for your machines: it must be compact, robust, and versatile. Distributed across nine essential sub-processes, clearly arranged below. Discover what we can mean for you during each step.

First cleaning

Cleaning silicon wafers removes invisible dust. Crucial, because even the smallest speck of dirt is a no-go.

Exposing

A circuit pattern appears on the wafer. The sharper the projection, the better the eventual circuits work.

Developing

The exposed parts of the photoresist dissolve. Allowing the remaining layer to serve as a template for etching.

Etching

Chemicals or plasma selectively remove parts of the material. Dry etching creates the details, wet etching takes care of the larger patterns.