Etching: essential accuracy for material removal

Etching turns photoresist patterns into circuit structures on underlying layers. Whether using plasma or chemicals, this step demands precise material removal. Our components support consistent, reliable results across every wafer. Ensuring the stability your process relies on.

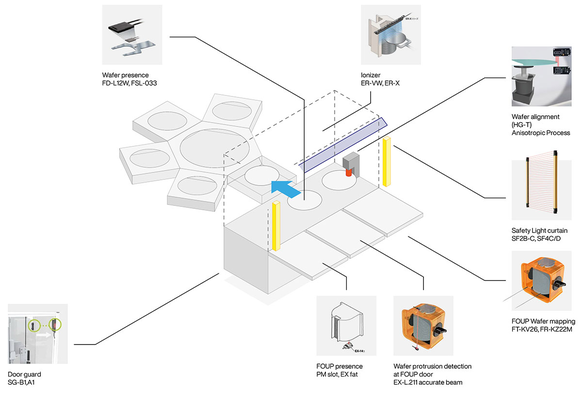

Technology for dry plasma etching

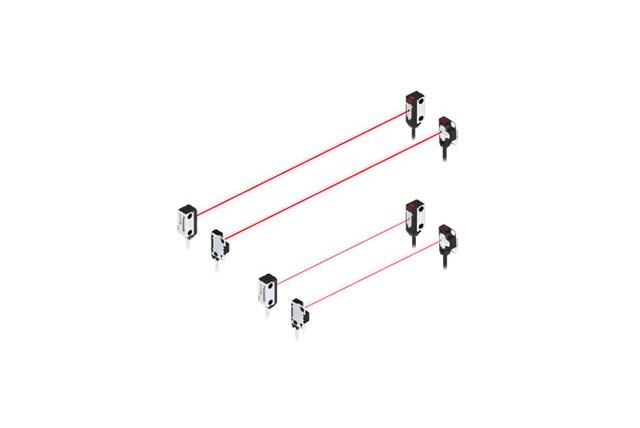

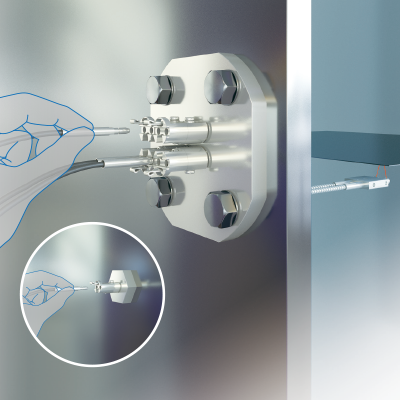

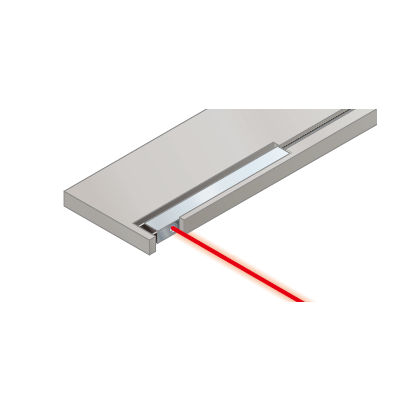

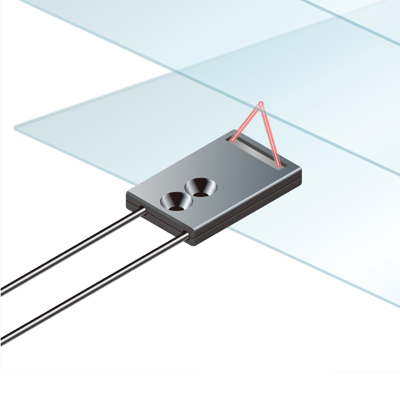

Etching typically refers to dry etching, where plasma or reactive gases selectively and directionally remove material from exposed areas. Achieve optimal process control with our sensors for wafer positioning, chamber stability and endpoint detection. While our ionizers neutralize static charges that attract particles, our precision components help maintain a clean and controlled environment.

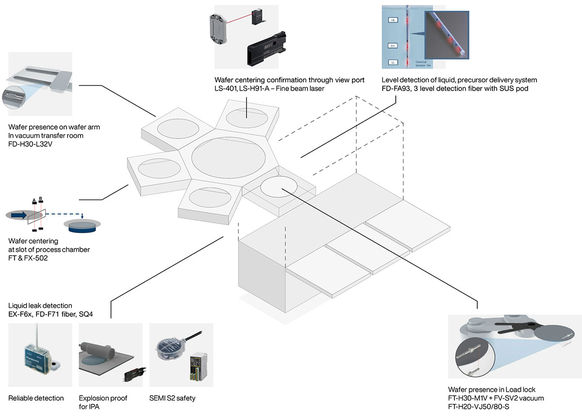

Enabling results in wet chemical etching

Wet etching uses chemical solutions to remove material in a more isotropic manner, offering cost-effective processing for larger features and bulk etch steps. Maintain precise liquid handling and wafer positioning with our sensor technology to ensure uniform, repeatable results. From leak detection to level monitoring, our components stabilize the chemical environment while supporting safe and consistent processing.