Exposing: essential precision in pattern transfer

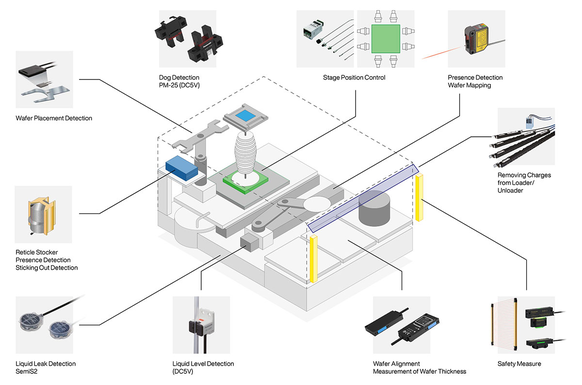

In the exposing step, UV light projects circuit patterns onto a photoresist-coated wafer. That takes accuracy, as even the tiniest shift or blur has impact. Stay ahead of those risks and create precise patterns and alignment to make sure every device works as intended.

Equip high-precision lithography systems

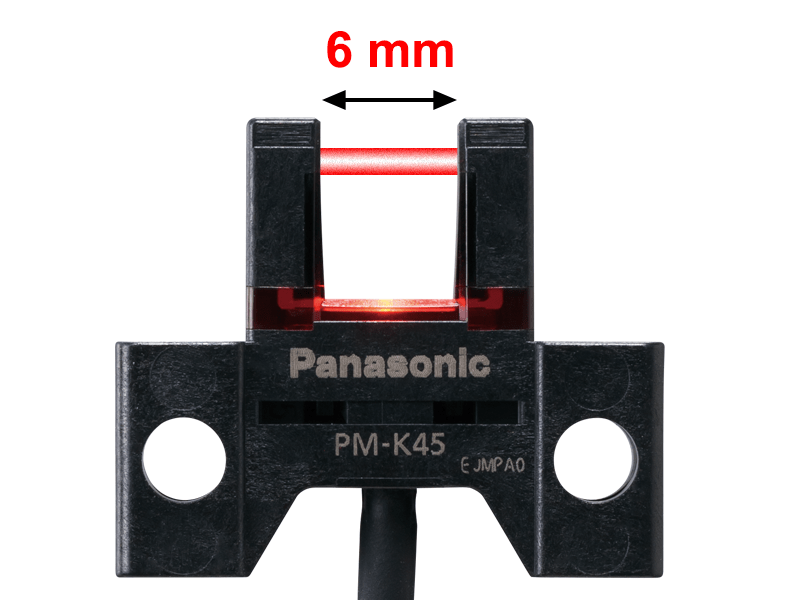

Exposing calls for exact wafer positioning, stable stages and accurate reticle alignment. Therefore, our sensors handle wafer detection, stage monitoring and alignment feedback. And to stop particles from settling? With our ionizers you remove static charge where it matters most.

Supporting next-generation lithography requirements

As chips get smaller, tolerances tighten and contamination becomes more of a risk. Advanced masks and exposure tools need nanometer-level stability. That means precise motion, clean conditions and reliable monitoring. Our components help you keep control. Ranging from accurate alignment to effective charge management, now and for the future.