User story Rombouts

At the end of the day, a product is just a product. That sounds a bit strange, especially when advanced technology is the basis. Yet a product only leads to success when everything around it is right. So they know at Rombouts, Belgium's purveyor of quality coffee. Panasonic lasers do their work on the production floor. And each time they are tailored to a specific situation.

Rombouts is certainly a contemporary company. But they are just as proud of their own history here in Aartselaar, just south of Antwerp. So visitors can see the wooden cart that used to move the coffee around in the entrance hall. And look, a little further on, the old industrial roaster with which it all started in 1896. Would Frans Rombouts have suspected at the time that this roasting drum would lead to the coffee roaster of today?

Rombouts' story is a special one. From the first producer of the individual coffee filter, the company became Belgium's certified purveyor to the royal household. And from its collaboration with French Cafés Malongo, it went on to fair trade products and making a cup of espresso at lightning speed with coffee doses. The latter also typifies Rombouts; innovations keep the company at the forefront as a supplier for individuals, the catering industry and businesses. And through it all, explains Frank Van der Goten, that quality always runs. "That is what we stand for. Rombouts, that's quality in the bag."

Much automated

Frank is manager of Projects at Rombouts. He has worked there since 2003 and saw up close how the company developed. Take automation alone: especially in recent years it went fast. "The whole roasting process, but also mixing: a lot is automated," Frank says, as he leads the way towards the production floor. There, a little later, it becomes clear just how many processes and operations technology now takes care of here. So too where it concerns the markings on each can, intended to indicate best-before date and batch.

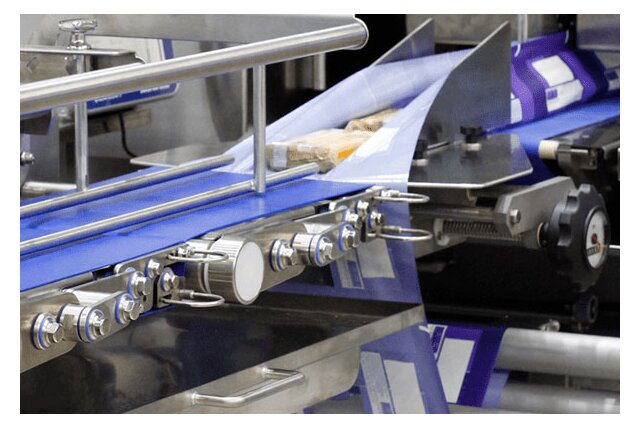

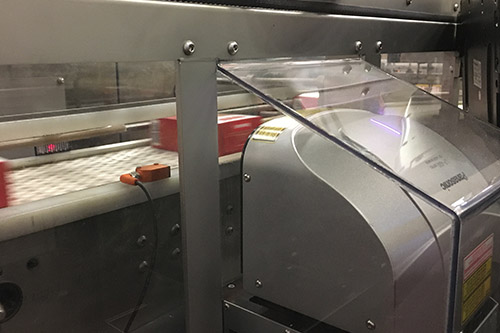

As the cans full of coffee spin down the line, a FAYb laser provides them with the information they need at lightning speed. It turns out to be even less than a second's work, as fast as laser marking goes every time. Frank looks at the laser marking system with satisfaction. As does his colleague Nick Van Zoom, team leader of technical services. Where previously information was punched out, Nick says it is now done much more efficiently via laser marking. "We hardly have to worry about it anymore. The risk of errors is much less, also we can link to our ERP system."

Accurate synchronisation

It was late summer 2019 when Frank turned to Panasonic Industry for the laser marking system. "We had worked well with them in the past, then for a vision project. The contact has always remained. So when we wanted to work on this can line, we quickly knew where to go." Especially also because this assignment was quite specific, Frank emphasises. "This involves moving cans, which requires precise synchronisation with the machine. Moreover, space at the line is limited."

So the challenge was not so much in the system itself, says Luc Aalders, key account manager at Panasonic Industry. "Every application is different. Also here. We quickly knew which laser we needed, but with it we wanted to interfere with the machine as little as possible. You see, a product itself doesn't make a project successful. Everything around it does. Think of a good coordination of the specifications. About advice, timely tuning and a good construction of the system. A product only becomes good with the right feel for the customer's demand."

Suddenly a second project

Moreover, it didn't stop there. Because only just discussing the laser at the can line, an old CO2 laser for markings on cardboard packaging broke down in the hall. "Here replacement proved easier than at the can line", says Frank, "although this laser had to be there as soon as possible. That is why we asked Panasonic for this project as well. That worked out well, with a new laser within a few days. We kept production downtime to a minimum."

Like the CO2 laser, the FAYb laser also has an enclosure for the required safety. Moreover, with such success for both projects, Rombouts and Panasonic Industry are now talking to each other about a third laser application.Nick: "Panasonic has knowledge of technology, but also an insight into the general approach of a project.The latter is at least as important."And what about personal contact, says Frank."Just that involvement.We value it a lot. Informing us about our needs and then working together on a project: it is the basis for a successful project."

A century and a half of passion for coffee

2021 marked the 150th anniversary of the coffee roaster from Belgium. It was a year in which the company looked back on its own rich history. At the time when, among other things, it became Belgian purveyor to the royal household and made a name for itself with fair trade products.Yet a jubilee year like this also lends itself well to looking into the future. Because at Rombouts they are used to anticipating the future.Hence the innovations such as the 1,2,3 Spresso system in the 1990s.And hence its own R&D department, which underlines the coffee roaster's pioneering role.Quality and experience: at Rombouts, they bring it together every day in every cup of coffee.