User story Habraken

Habraken's industrial sewing machines are shipped from Kaatsheuvel to the entire world. The applications vary widely, and customer requests are often unique. One such request was for a machine to stitch cinema screens over a length of 15.5 meters. Habraken collaborated with Apex Dynamics and Panasonic Industry to create a custom machine in a short time.

Much of the process today is fully automated, so one might think that this also applies to industrial sewing machines. Over a century and a half ago, they hit the market as one of the first mass-produced machines. However, not much has changed since then. This gives the sewing machine a certain steadfastness, although it primarily speaks to the technology itself. It requires specific handling by the operator, and according to John de Rooij, full automation is simply too early. He is convinced that robotics will also come to industrial sewing machines. “But then the machine must adapt to the robot. That seems to me to be the wrong way around.”

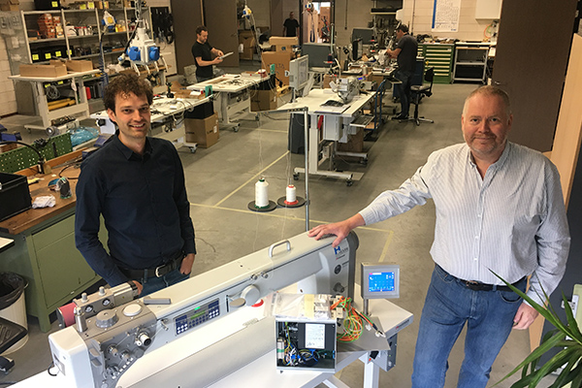

Such a familiar technology as that of the industrial sewing machine. So stable and so self-evident. John speaks enthusiastically about it as the manager of the R&D department at Habraken, which imports, modifies, and distributes industrial sewing machines. It is specialized work, with customer requests that vary significantly. The machines from Habraken's facility in Kaatsheuvel are used in various industries, including the automotive industry, which uses them for car seat upholstery. Sailmakers also rely on Habraken's expertise, as do manufacturers of ready-to-wear clothing and sunshades.

Ultimately, the industrial sewing machine is the foundation of countless end products, John explains. To pioneer with it and discover further applications: John and his colleagues at Habraken have all the space to do so. And believe him, that is more than just nice. “The technology in our machines; I find it super fascinating.”

More than just supply

Habraken handles much in-house, from engineering and assembly to programming their own software. And when it comes to controlling the machines? They have a partner like Panasonic Industry, with whom Habraken has collaborated for years. This is to John's satisfaction, as he has been with the company in Kaatsheuvel for about twenty years. “Panasonic is more than just a supplier for us. If we want to explore the possibilities of new applications, I like to involve Panasonic. The team is engaged, takes our questions seriously, and thinks along with us. If an application later turns out to be possible, Panasonic informs us about it. We greatly appreciate their effort to research for us and share knowledge.”

With the questions from a specialist like Habraken, a solution is not always obvious, knows Roel Lommers, key account manager for Projects & Support at Panasonic Industry. “But that’s not a problem; on the contrary. It is precisely because of those unusual questions that we learn from each other and keep each other sharp.”

Mass inertia has an impact

How versatile an industrial sewing machine can be was evident at the end of last year. Stitching cinema screens was the request from Habraken's customer. And that over a distance of 15.5 meters, with the machine needing to move along the table at the same speed as the fabric is being stitched. John: “This was a special assignment for us, especially due to the mass inertia. That would obviously have an impact if the machine suddenly stopped.”

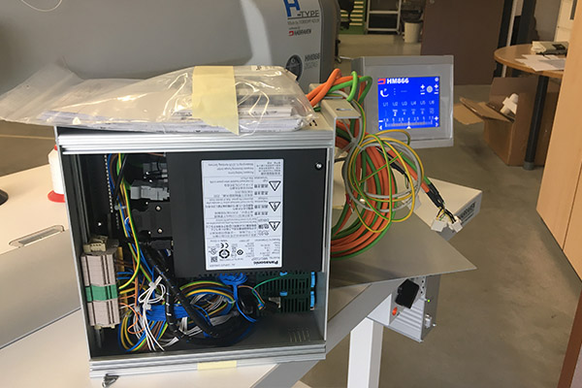

John presented his request for the right control to Panasonic Industry, which in turn consulted Apex Dynamics from Helmond for advice on the choice of rack and pinion and transmission. Together, the partners came up with a solution that, in addition to a PLC and HMI, consists of a servomotor and drive combination with a specific feature. Roel: “The drive has an autotune function that essentially probes the machine's behavior for aspects such as stiffness and positioning. By collecting data over a longer period, the function ensures the correct parameters in the drive.”

From drawing to technology

A PLC, HMI, and servomotor: that sounds like an obvious control solution, Roel realizes. “But which versions do you choose? How do you translate the initial drawing into the final technology? The process of making those choices and getting the solution up and running was the challenge. I think we succeeded well with Habraken and Apex, especially considering the relatively short time of six weeks.”

Like Roel, John is also satisfied with the machine. “It works well, and our customer is enthusiastic about it. This is certainly due to the swift progression of the project, where Panasonic not only assisted us with the control technology but also provided HMI training and machine programming. This characterizes our broad collaboration with Panasonic, which also helps us with supply chain logistics. Such a broad collaboration is very valuable for our company.”

Innovating to grow

The right industrial sewing machine, time and again. With technology for every application, Habraken has built a strong reputation, with customers worldwide. The company supplies machines from well-known brands from a modern facility in Kaatsheuvel, is the exclusive importer of Dürkopp Adler machines for the Benelux, and also serves the market with its own brand, HM. Habraken is a family business, has a smaller branch in Belgium in addition to the Kaatsheuvel location, and currently employs around 25 people. With its own R&D department, Habraken places a high priority on innovation as a solid foundation for the intended growth in the coming years