Biofluidix: The greatest precision for the smallest drop

Reliable results require unambiguous conditions. BioFluidix specialises in this, with dosing technology for liquid of the smallest amounts and has already developed and patented many. But to grow only with existing products from now on? Surely not, as proven by its collaboration with Panasonic Industry. "Ultimately, everything is about creating value."

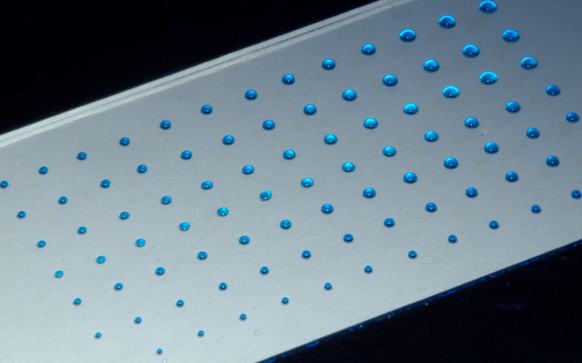

Precision can always be even more precise. Especially for control and detection at the smallest level, even when it comes to liquid dosing. So, when they talk about ultra-low volumes at BioFluidix, based in Freiburg, southern Germany, then - according to co-CEO Andreas Ernst - they are talking about picolitres or the low nanoliter range. About no more than the smallest drop, from which a lot can be deduced. Think, for example, about the volume of the droplet and about its quality.

The more grip on all those droplets - and thus the more similar they are - the more reproducible they become. And that is exactly what BioFluidix helps customers with, says Andreas, whose responsibilities at the company include marketing and sales. Hence, he has a good overview of the market, sees how fast lab automation is developing and notices the growing customer need for further miniaturization. Take, for example, the developments of point-of-care applications, such as bedside testing. "If you want to move towards accurate quantitative testing, you need to know exactly what volumes are applied to the test. And we provide the latter."

Growing with Hamilton

Diagnostics, research and production: there is no shortage of demand from sectors such as pharmaceuticals and life sciences for BioFluidix. The company operates in a growth market, which also includes a player like Hamilton, which has owned BioFluidix since the end of 2022. "Hamilton focuses on the slightly larger volumes," Andreas explains. "As a result, we complement each other very well. Together we target new customers, together we go for new markets and ideas (see box 'Accurate through innovation', ed.)." Good chance, then, that the current BioFluidix team of around 20 employees will soon be a lot larger. "Our cooperation is partly aimed at increasing our sales figures. Growth is definitely the plan."

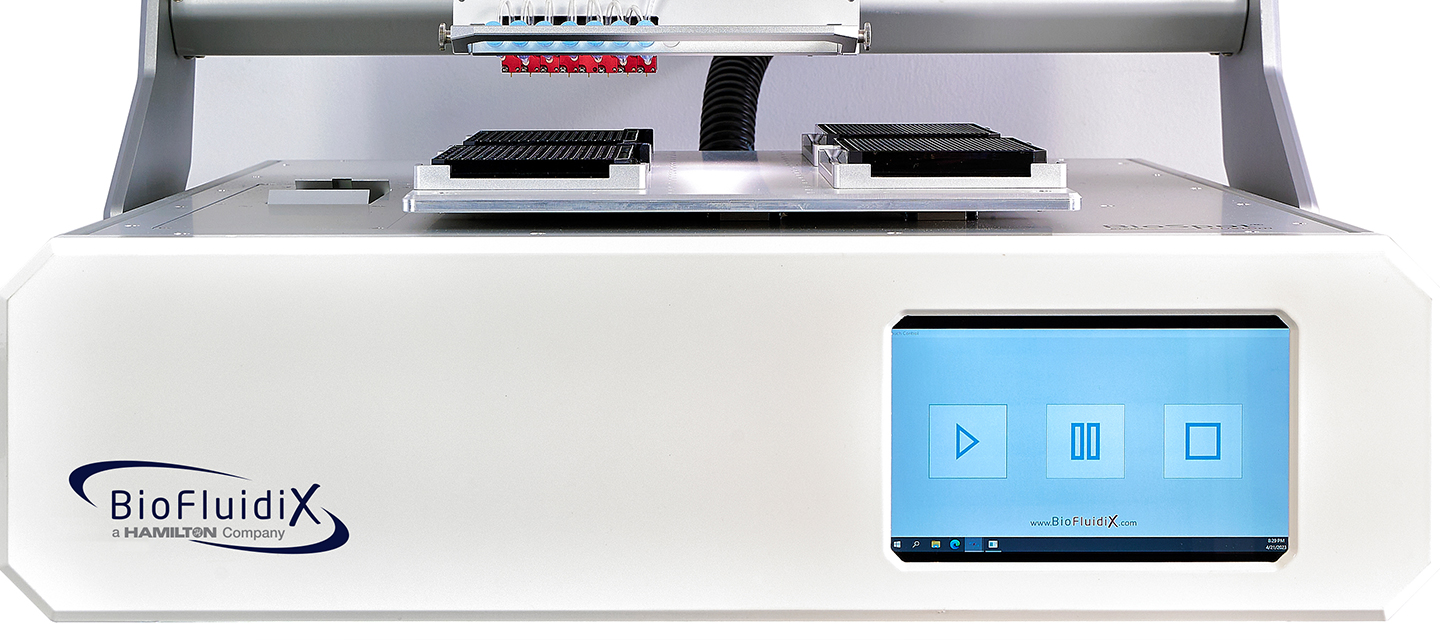

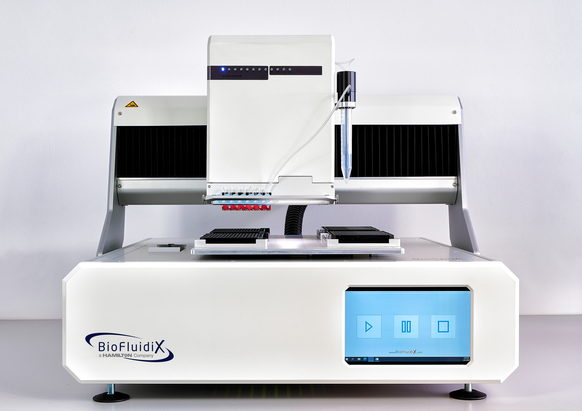

On the one hand, this involves increasing sales of BioFluidix's current products, such as its patented PipeJet® dosing technology.

This is robust, Andreas explains, and is characterised by easily interchangeable nozzles. "The customer uses the nozzles as consumables, which avoids expensive cleaning processes. A unique feature in our market." On the other hand, Andreas says there is customisation, for which BioFluidix deploys a wide range of composites customer-specifically.

"In the end, we don't so much sell products as offer solutions. We adapt our technology to the customer's needs and have the engineering capacity for it in-house. To respond flexibly to any demand: it is the strength in everything we do."

Selling more than products

For process optimisation and keeping control at all times, BioFluidix relies on Panasonic Industry's products, among others. Initially, this only involved detection by fork sensors, says Nils Lass, BioFluidix's other CEO and responsible for technical development and production.

"Panasonics sensors are well known in the market. We include them in almost every product."

And that the company now uses more than just the fork sensors? For that, we must go back to 2018, before the visit by Wolfgang Held, business development manager lab automation at Panasonic Industry. "If I think we can help a customer with something, I am happy to engage in a conversation," says Wolfgang. "In the end, everything is about creating value. And we were certainly able to do that for BioFluidix."

Asking each other for input

During his visit, Wolfgang presented, among other things, Panasonics sensors for leak detection, which prevent liquid from coming into contact with electronics. He also drew BioFluidix's attention to the use of ionisers, which remove electrostatic charge and thus contribute to droplets ending up in the right position. A valuable addition, says Nils, who also emphasised the compact design of Panasonics products. "That makes them even more suitable for our applications. We are now using the leak detectors and ionisers in abundance, also for the prototypes we occasionally make."

Matching products with applications require knowledge of the customer’s market. With regular consultation and communication BioFluidix and Panasonic Industry have achieved this.

Take for example the position of the ionizer, according to Wolfgang. "Even the smallest drop should not get stuck or left anywhere in the application along the way. We looked closely together at how to avoid this and chose to mount the ionizer in the dosing head, so that positively and negatively charged ions pass through the dosing application directly from there. I think it is a great example of how our product offers optimal value for the customer."

Attention to potential

Developing such an ionizer ourselves is simply not within BioFluidix's focus, Andreas says. "That is why it is good we are in discussion with Panasonic about this. Although we will grow together with Hamilton, we are not the largest customer for Panasonic. That there is then still so much attention to us, I think is unique. If we want to consult, we do so directly with Wolfgang. It makes our cooperation approachable."

Wolfgang hears Andreas' words with a smile. "There is an awful lot going on within lab automation. The sector has been growing for years, has a lot of potential. And that certainly applies to companies like BioFluidix, which often work closely with a university. These are the companies where the new applications come from. To do this together as we are now doing with BioFluidix: it is the basis for true partnership."

Accurate through innovation

Responding to the future requires innovative solutions. They also realise this at BioFluidix, as evidenced by, among other things, the in-house developed AllDrop® nanoDispenser printhead. This checks each individual drop in the process and contributes to greater efficiency for personalised medicine use. Every drop is measured and documented, making every dispensing fully traceable. Another innovation are so-called microneedle coatings. Think of these as tiny patches, where BioFluidix' technology ensures that microneedles receive the right volume of reagents or drugs every time.

Downloads

| Name | Size | Date | Language |

|---|---|---|---|

| User story Biofluidix | 376 KB | 01.09.2023 | English |