Getting started with the IIoT? Berg Hortimotive shows you how accessible it can be!

A new controller has already given their spraying robots a hefty boost. Yet they don't want to stop there at Berg Hortimotive. Process optimisation is what matters now. Obtained thanks to analysis and insight, via the applications of the Industrial Internet of Things (IIoT). Starting with the new control system, the company has everything it needs.

Berg Hortimotive supports greenhouse horticulture worldwide. The company, based in De Lier in South Holland, improves, and speeds up processes in greenhouses. This includes the BeMatic Meto spraying robots. These drive over a rail system into the customer's greenhouses, spray the crops there and thus provide the necessary protection. All this is very effective and efficient too, as the robots save the customer a lot of time.

For every customer worldwide

The Metos have recently acquired a new controller. It consists of components and software supplied by us, and we helped Berg Hortimotive with its integration. We logged into the test environment, watched, and made adjustments. And often did all that remotely, for a future-proof basis for the Metos. Because more than just a new controller, Berg Hortimotive can move towards greater insight with it. Obtained via the digital network of the IIoT, in which components together provide remote visibility and support.

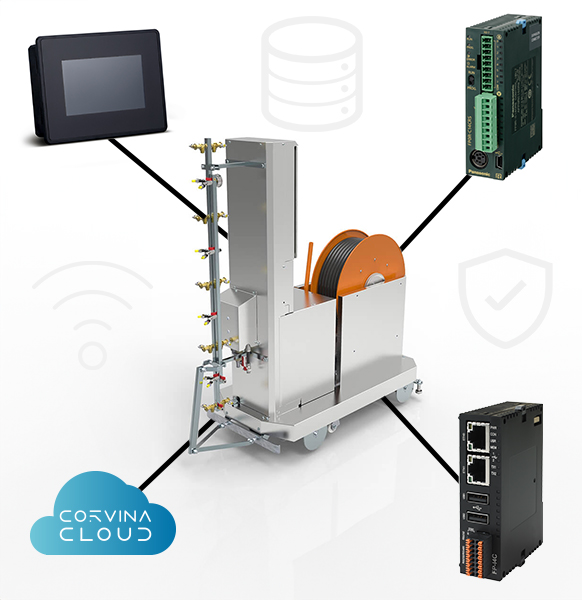

PLC FP0R

In the Meto, the compact FP0R forms the heart of the control system. In addition, the PLC serves as an external measuring device. For example, how often is a specific function switched? The FP0R logs such data and stores the data, after which the user can transfer it to Corvina Cloud via the HMI.

HMI HMe04

A Human Machine Interface (HMI) visualises processes. So too in the Meto, where the user can manage those same processes via the screen. The HMe04 is a low-threshold version of an HMI. It is user-friendly and free of unnecessary functions. However, the unit does provide the - obviously secure - link between a machine and Corvina Cloud.

Corvina Cloud

Our online platform for the IIoT. OpenVPN- and SSL-based and the application for connections between machines, users, and devices. Corvina Cloud provides access to a centralised dashboard, including the real-time status and location of all machines. So, catching up is quick, thanks to remote monitoring and support at any time.

Predictive maintenance

How often has a Meto been started at a customer's premises? How often did the robot spray, how often did it enter a path? These are such parameters that Berg Hortimotive can already log. And - provided the collected data are linked correctly - can use them for predictive maintenance, for instance. As a result, the robots continue to function optimally, their lifespan is extended and there is also more grip on the supply chain.

Always and everywhere anticipating. React and decide at lightning speed. A start in IIoT is quickly made, as the situation at Berg Hortimotive shows. Curious about the potential of the digital network for your organisation? Ask us about the possibilities - we would be happy to help you.