Automotive electrification

Check out our versatile product portfolio

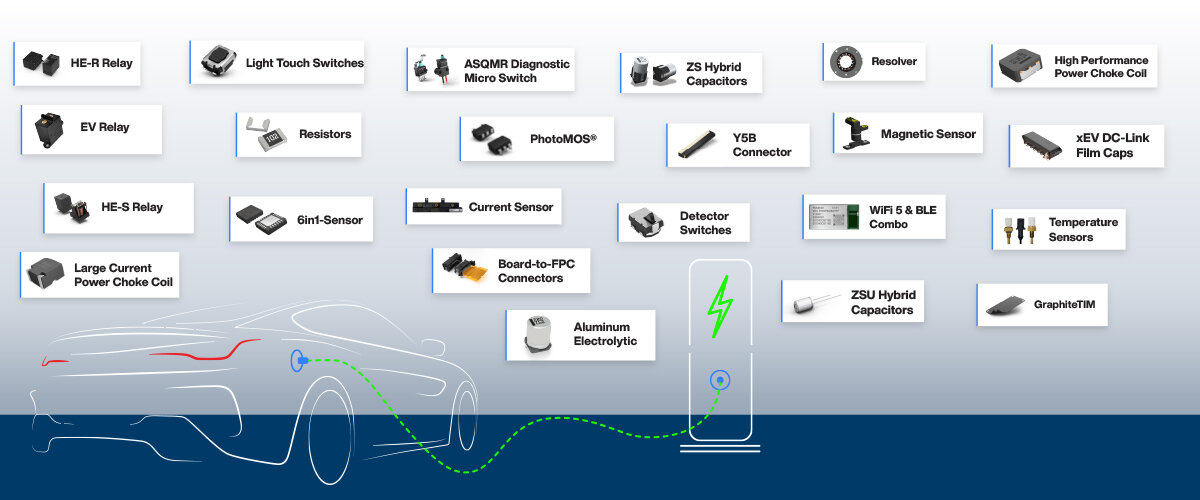

Miniaturisation, energy efficiency, electrification, safety and reliability - the specifications of today's automotive industry are extensive.

However, the fact that ideas do not remain lip service, but ultimately make it to series production, is in the end often a question of components such as relays, sensors, or capacitors, which deep under the bonnet (or in the charging station!) are decisive in making new technology available, affordable and reliable.

Check out our "treasure map" of where exactly innovation manifests itself in the smallest detail today. Certainly not complete - but all the more impressive.

The Importance of Passive Components in Automotive Electrification: Enhancing Efficiency and Reliability of Electric and Hybrid Vehicles

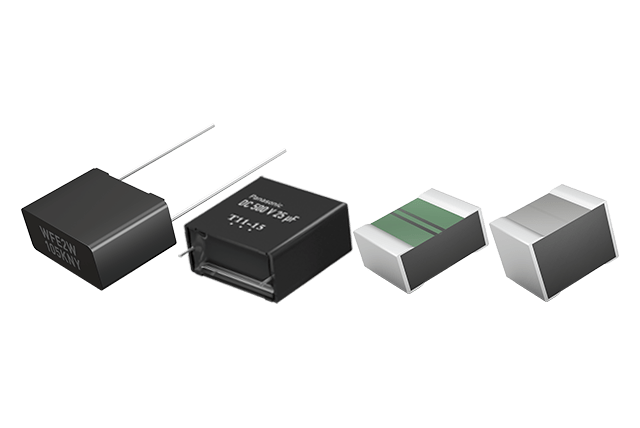

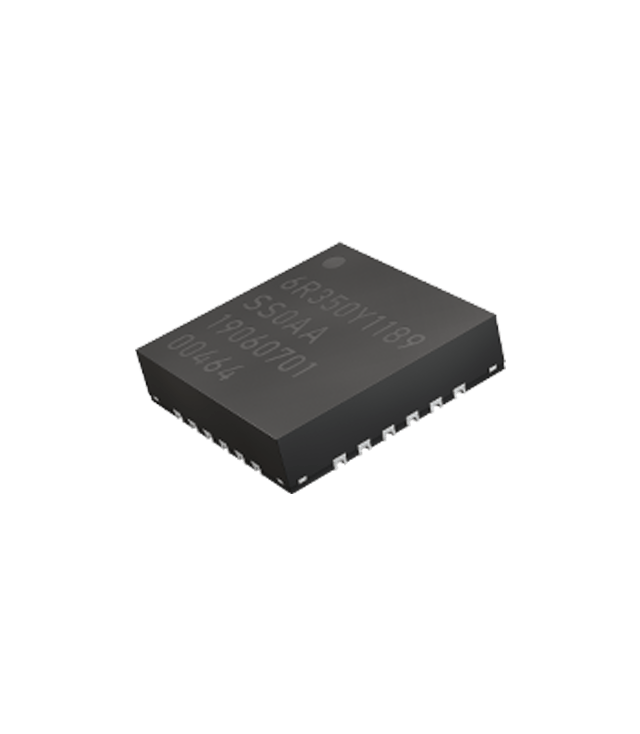

As the automotive industry transitions towards electrification, passive components are becoming increasingly important. Passive components are essential electronic elements that do not require a power source to operate, such as capacitors, resistors, and inductors. These components play a critical role in the design and performance of electronic systems in modern vehicles, particularly those that are powered by electric or hybrid powertrains.

One of the primary benefits of passive components in automotive electrification is their ability to regulate voltage and current. For example, capacitors can store and release energy, providing a stable power supply to critical components in the vehicle's electrical system. Similarly, resistors can limit the flow of current, protecting sensitive electronics from damage. By using passive components, engineers can design more efficient and reliable electrical systems that are better suited to the unique demands of electric and hybrid vehicles.

Passive components are critical for the successful electrification of the automotive industry. By providing reliable voltage and current regulation, protecting against EMI and voltage spikes, and reducing the overall size and weight of electrical systems, passive components play a vital role in the design and performance of modern electric and hybrid vehicles.

Downloads

| Name | Size | Date | Language |

|---|---|---|---|

| AEC-Q200 Passive Components Selection Guide.pdf | 1 MB | 18.12.2025 | English |

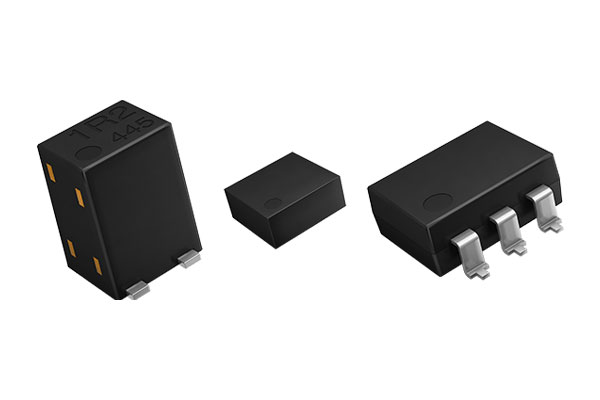

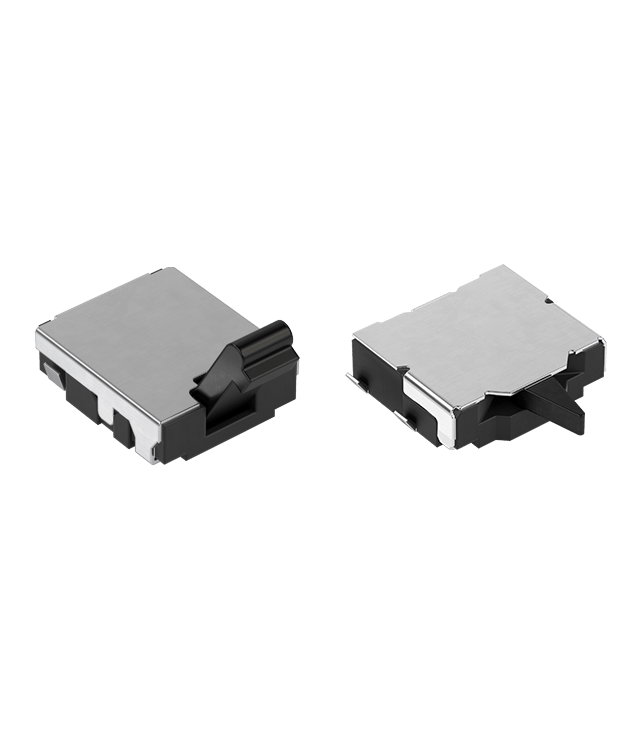

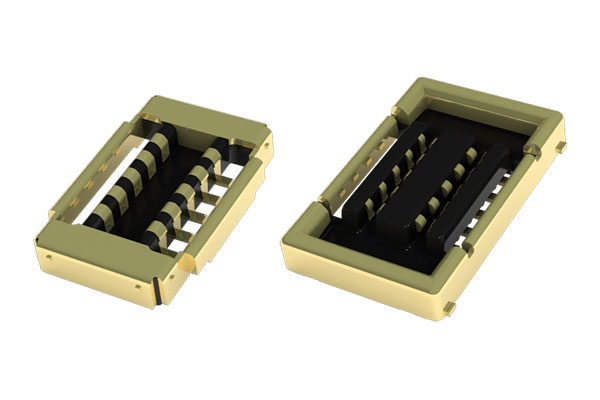

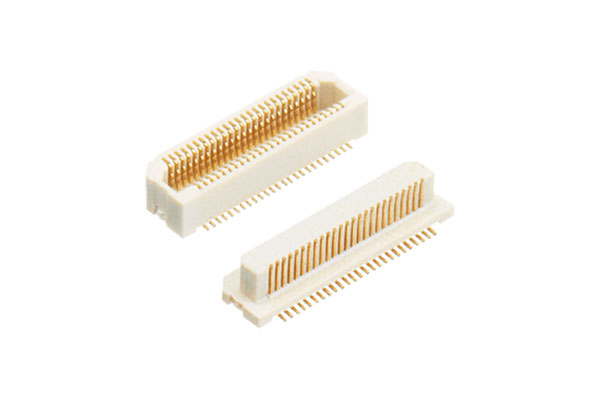

Electromechanical Components and Couplers: The Crucial Role in Advancing Automotive Electrification

Electromechanical components and couplers play a crucial role in automotive electrification.

Relays and switches are used to convert electrical energy into mechanical motion or vice versa. They are found in various systems within a vehicle, including power windows, door locks, HVAC controls, and electric power steering.

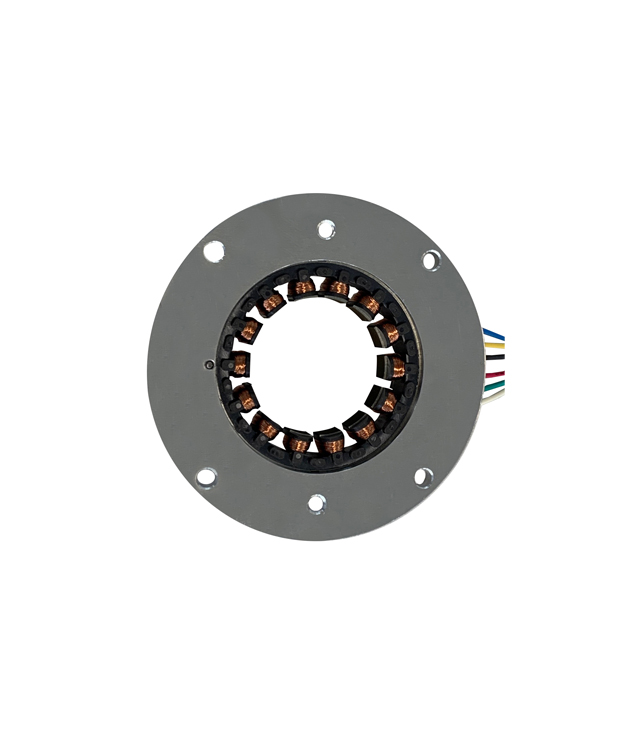

In electric and hybrid vehicles, electromechanical components are also used in critical systems, such as the electric motor and battery management system. For example, electric vehicles rely on electric motors to convert electrical energy into mechanical energy, propelling the vehicle forward. These motors require sophisticated control systems that utilize electromechanical components to regulate speed, torque, and efficiency.

Another important component of automotive electrification is couplers, e.g. connectors. They are used to transfer power and data between different components in a vehicle's electrical system, such as the battery, motor, and controller. They can be designed to handle high voltages and currents while maintaining a secure and reliable connection, even in harsh operating conditions.

These components enable the conversion of electrical energy into mechanical motion, regulate critical systems within the vehicle, and transfer power and data between different components. Without these components, electric and hybrid vehicles would not be able to achieve the levels of efficiency, performance, and safety that are required for widespread adoption.

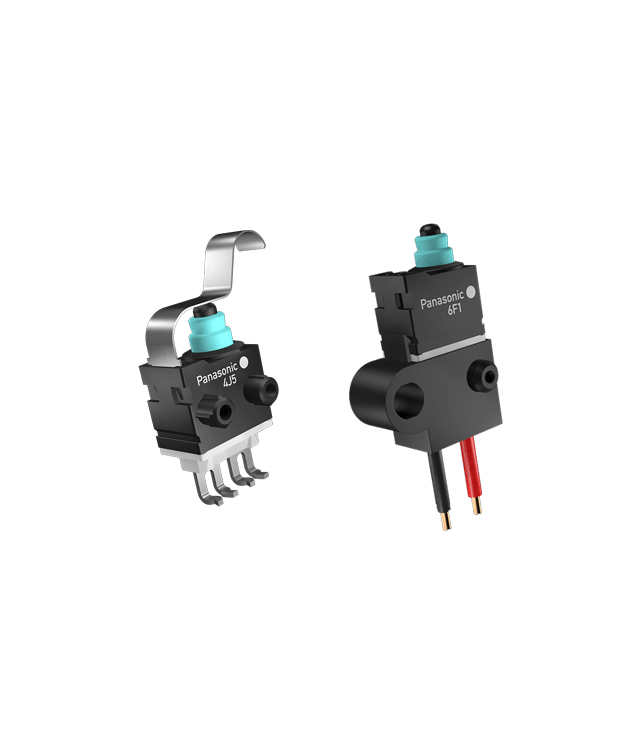

The Role of Sensors and Wireless Connectivity in Advancing Automotive Electrification

As the automotive industry continues to shift towards electrification, the role of sensors and wireless connectivity in modern vehicles has become increasingly important. These technologies provide critical information about the vehicle's performance, enabling better control and management of electric and hybrid powertrains.

Sensors are used throughout the vehicle to measure various parameters, such as speed, temperature, pressure, and position. In electric and hybrid vehicles, sensors are particularly important in the battery management system, where they are used to monitor the state of charge and temperature of the battery cells. By providing real-time data about the battery's health, these sensors enable more efficient and reliable operation of the vehicle's electric powertrain.

Wireless connectivity is another key technology in automotive electrification. It enables communication between different components of the vehicle's electrical system, such as the battery, motor, and controller. This communication allows for better coordination and control of these components, leading to improved performance and efficiency. Wireless connectivity can also be used to connect the vehicle to external networks, such as the internet or cellular networks, enabling remote monitoring and control of the vehicle's systems.

Thermal Management Essential for Safe and Efficient Electric and Hybrid Vehicles

Thermal management technologies are essential for the safe and efficient operation of electric and hybrid vehicles, helping to regulate temperatures and protect critical components from damage.

One of the primary benefits of thermal solutions in automotive electrification is their ability to regulate the temperature of the battery pack. Lithium-ion batteries, which are commonly used in electric and hybrid vehicles, are sensitive to high temperatures, which can lead to reduced performance and a shortened lifespan. By using thermal management technologies, such as cooling systems or thermal insulation, engineers can regulate the temperature of the battery pack and ensure that it operates within safe and optimal parameters.

Another critical application of thermal management in automotive electrification is the regulation of the electric motor. Electric motors generate a significant amount of heat during operation, which can reduce their efficiency and reliability. Thermal management technologies, such as liquid cooling systems or heat sinks, can help dissipate this heat, enabling the motor to operate at higher efficiencies and ensuring that it has a longer lifespan.

Thermal management solutions are also used to regulate the temperature of power electronics, such as inverters and converters, which are responsible for converting DC power from the battery into AC power for the motor. These components generate significant amounts of heat during operation, and thermal management technologies are used to dissipate this heat and protect them from damage.