Less weight, far better handling: Panasonic’s new electric fan motor helps miniaturizing outdoor HVAC units like monobloc heat pumps

The demand for air conditioning systems is unbroken, but the handling of the necessary, so-called “side-discharge type outdoor units for commercial air conditioners” often turns out to be difficult:

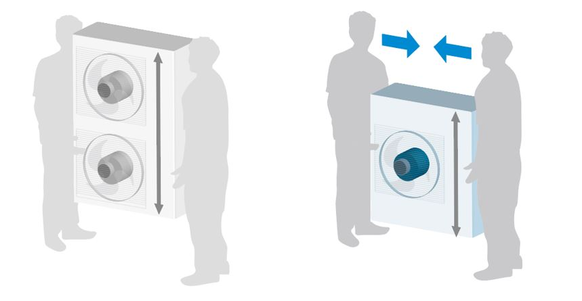

Those outdoor units are to be installed in well-ventilated locations that are not directly exposed to rain or direct sunlight (particularly relevant when using natural refrigerants like propane, R290). In reality, those locations are often small, narrow and too complicated to access. At least too complicated to use carts or cranes to ease the transportation process of those heavy and unhandy devices. A conventional outdoor unit is typically 1.5m in height and as heavy as approximately 100kg.

Given those dimensions, manually manoeuvring those heavy units to the point of installation with a very limited view is everything but an easy task for the installation workers.

So, the challenge was to reduce the unit in terms of height and weight: Panasonic successfully tackled the issue with an innovative fan motor concept with increased performance at a similar size. The result: the outdoor HVAC unit can be operated now with only one single fan motor that replaces the conventional two-motor concept.

A complete redesign of the motor’s core magnetic structure

Basically, the shift to a one-fan-motor concept in the outdoor HVAC system would require a larger motor - and correspondingly fan - to maintain the same output level of air volume. However, the use of a larger motor would counteract the new design approach and purpose to significantly lightweight and miniaturize the concept.

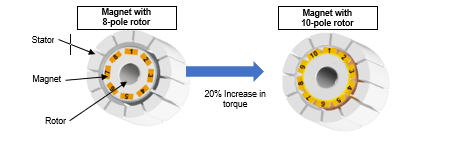

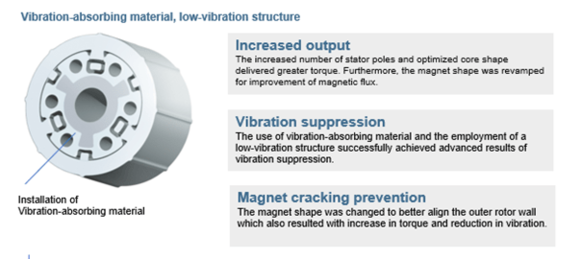

A deeper look and new approach to the motor design has been necessary to make the one-motor-idea work. There have been several changes to the magnetic core of the motor. One improvement example was an increase in the number of poles in the magnetic circuit. The magnetic flux also has been optimized by revamping the core shape. Finally, the magnets have been redesigned - which resulted in an increased motor performance without any increase in size of the motor’s outside diameter.

Having, however, increased the motor’s power at its equal size, the increased risk of the rotor magnets cracking due to vibration required further and through investigation. But, this also could be reliably resolved by integrating Panasonic’s anti-vibration material into an entirely new rotor structure.

“Our new motor significantly helps to minimize the size and weight of, for instance, those outdoor units. Considering the sheer number of units being installed worldwide on a daily base, it really relieves the workload and ergonomic burdens for many installation workers – a valuable contribution to make people’s lives a bit easier again”, summarizes Inoue Jiro from Panasonic Industry.

Features

● Rated output: 70 to 180W

● Number of poles increased to 10 to achieve high efficiency and low vibration.

● Equipped with vibration-resistant rotor (measure against torsional resonance)

● Application: Multi-split air conditioning systems or Heat pumps