Our products in semicon applications: LS-500 series

In high‑precision semiconductor manufacturing, wafer handling accuracy is critical. Even the smallest deviation in wafer position can lead to mis‑picks, collisions, rejects, and costly downtime. One of the most effective ways to prevent these issues is protrusion detection, verifying whether a wafer is sticking out of its slot beyond the allowed tolerance.

Why protrusion detection matters

As wafer diameters increase and materials diversify, handling robots face tighter requirements. A protruding wafer of just a fraction of a millimeter can have major consequences:

- Mechanical interference during picking

- Increased risk of wafer edge damage

- Lower overall tool availability

- Higher operational cost due to stopped processes or scrapped wafers

To maintain reliability, fabs depend on highly stable, highly repeatable sensors capable of detecting minimal deviations, regardless of wafer material or reflectivity.

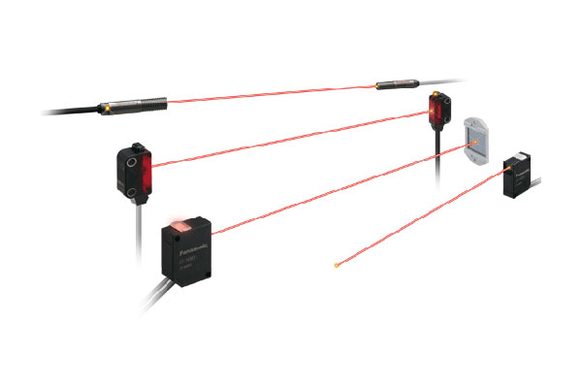

Proven performance: Panasonic LS‑H901 (LS‑500 Series)

During recent application testing, the Panasonic LS‑H901 confirmed its exceptional performance in protrusion detection tasks. The sensor demonstrated stable detection across various wafer types, including:

- Silicon

- Glass / transparent wafers

- SiC (Silicon Carbide) wafers

The key: its coaxial retro‑reflective optical principle, which ensures consistent results even in the most challenging conditions.

What is coaxial retro‑reflective sensing?

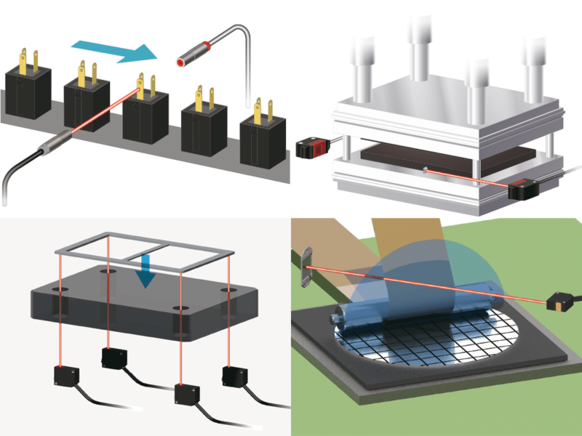

In a coaxial retro‑reflective setup, the sensor emits and receives light along the same optical axis. A dedicated reflector returns the beam to the receiver.

This configuration offers significant advantages for semiconductor applications:

Key Benefits

- Reliable detection on difficult surfaces

Works even with transparent or highly reflective wafer materials. - Low sensitivity to wafer tilt or angle

Minimizes false detections caused by slight misalignment. - Compact sensor head

Simplifies integration into tight end‑effector or FOUP/SMIF environments. - High repeatability

Essential for detecting very small height or position deviations. - Quick, repeatable setup

Through the LS‑500 amplifier with intuitive configuration.

Industry 4.0 ready: intelligent monitoring via EtherCAT

By adding the SC‑GU3 EtherCAT communication module, users gain:

- Remote sensor presetting and configuration

- Real‑time monitoring

- Predictive maintenance possibilities

- Seamless integration into PLC or PC environments

This makes the LS‑H901 not only precise, but also fully connectable for modern semiconductor equipment.