Predictive maintenance

Picture this: unplanned downtime devouring up to 30% of your operational costs, with mechanical failures as the main culprit. Preventive maintenance helps, but it's far from perfect. What if you could see into the future and prevent breakdowns before they happen? Enter predictive maintenance (PdM), for optimal machine health at all times.

The future of maintenance is in your hands

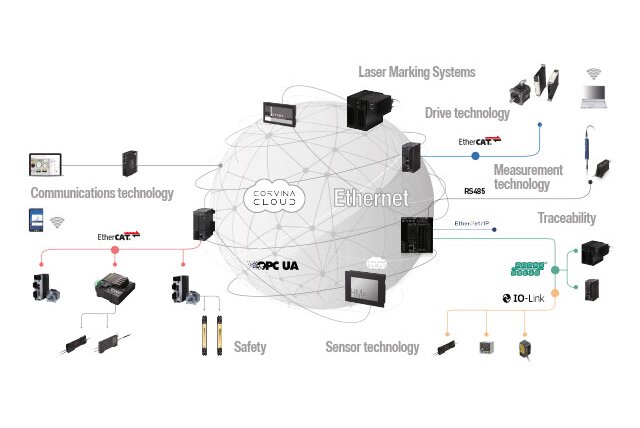

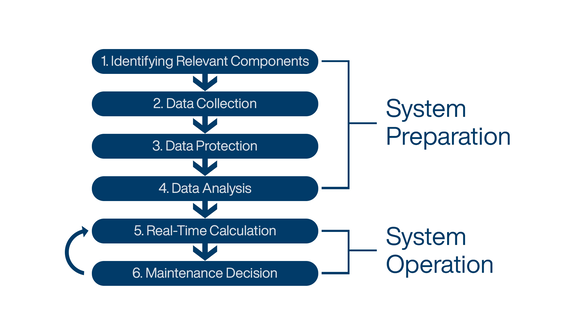

By leveraging sensor data and advanced analytics, predictive maintenance enables you to detect and prevent failures before they occur, optimizing your maintenance efforts and minimizing costs. Curious about implementing PdM in your organization? It all starts with a solid system preparation, based on four essential steps.

Harness the power of predictive maintenance

Don't let unplanned downtime drain your resources. Want to transform your operations, with future maintenance always on your radar at the right time? With the foundation well prepared, it's time to harness the power of data through a robust system operation.