User Story Autorette

To stay competitive, businesses must anticipate customer demands promptly. This is true in the market for car wash systems, where Autorette Carwash Systems has been a key player for years. The machines from this family business in Helmond are sold domestically and internationally, built on a foundation of thoughtful engineering. They are robust and simple, yet now more accessible as customers can control their installations remotely using Panasonic Industry's control systems. More visibility, more control: that's how versatile online management can be.

Improvement Requires Experimentation

Improvement involves experimentation and seeking new applications for a product that can be even better. It's about constantly reinventing oneself, says Gerrit Kalshoven, who oversees sales at Autorette Carwash Systems. Development, testing, and optimization are continuous processes for the installations produced in Helmond. Most installations are found throughout the Netherlands, with many also in Belgium and Germany. Autorette has also supplied customers in Switzerland and Italy. Experimenting with technology doesn’t always yield the desired results, but the company has managed for 45 years with only one maintenance technician. That says a lot about their efficiency.

Simplicity is strength

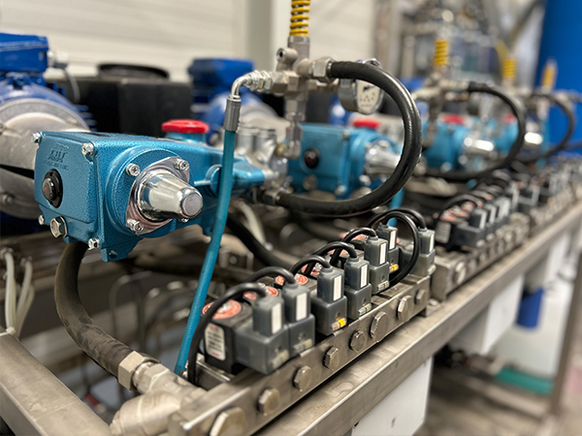

In his approximately 25 years at Autorette, Gerrit has seen the technology of the installations evolve, always with simplicity in mind. Customers should have minimal worries about their machines. Fewer components mean more stability. Less fuss means more reliability. For instance, the installation has a float tank at the back and a check valve at the front to prevent overflow. The supply and mixing of water and cleaning agents use the venturi principle, which relies on suction through low pressure, eliminating the need for additional pumps for shampoos. Customers need to understand our machines and maximize their efficiency. For example, the installation starts via electric valve relief, temporarily reducing system pressure. This is energy-efficient and allows for lighter motors compared to frequency control, offering significant savings, especially for customers with multiple wash boxes.

As good as the weakest link

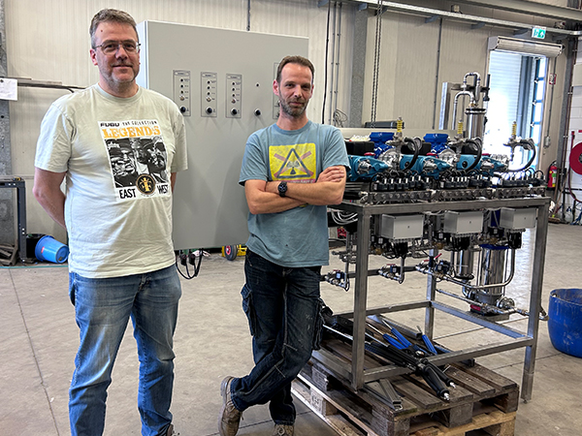

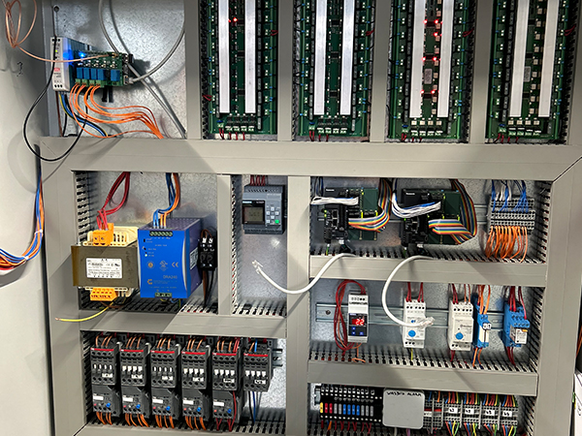

Autorette installations can last up to 25 years, supported by service contracts and customer trust. “Everything depends on trust. Customers are not just buying a machine; they are entering a long-term partnership with us. Hence, everything must be reliable. A machine is only as good as its weakest link,” says Gerrit. Autorette sets high standards, especially for the control system using Panasonic Industry’s hardware and software. What started with a single circuit board has grown into a strong collaboration. “Panasonic thinks along with us,” says Paul van Leeuwen, who co-owns Autorette with his brother John. “If we have a question or a customer faces an issue, Panasonic addresses it promptly.” In a rapidly changing field, this proactive approach is crucial, especially with evolving environmental requirements impacting installations and controls. “Panasonic explores possibilities with us, looking beyond just delivering products. It’s a pleasant collaboration.”

Image from left to right: Roy from Panasonic and Paul from Autorette.

Online offers double convenience

With expansion modules, one Panasonic PLC can control up to six wash boxes. Circuit boards connect the control to valves and coin boxes. While a human-machine interface (HMI) ensures user-friendly interaction, the control cabinet includes Panasonic’s FP-I4C, functioning as a controller between Panasonic’s PLCs and control platforms, offering internet connectivity and data collection for remote monitoring and adjustments. “Online control allows the customer to do much more,” says Gerrit. “This provides convenience and security, not just for the customer but also for us. We can monitor the control remotely, see how many hours an installation has run, and anticipate maintenance needs. We can even check if a customer’s frost protection is activated in winter. Everything we can control and adjust remotely saves us time and many trips to customers.”

Mutual understanding

With the current, compact control system, Autorette is ready for the future. The foundation is in place, with room for software adjustments for both control and internet functionalities. Roy Claessen, application engineer at Panasonic Industry, emphasizes the value of their long-standing collaboration. “We understand the criteria and parameters Autorette wants to set. This has led to a good exchange of knowledge, with mutual understanding even when the best solution isn’t immediately clear.” Ronald van Seters, key account manager at Panasonic Industry, agrees. “Most of our customers are in the industrial sector, a different environment from Autorette’s, but the questions are often similar. We can apply knowledge from other customers to Autorette and vice versa. This interaction works well.” According to Gerrit, it comes down to mutual reliance. “We know what we can say to each other, even under pressure. We can’t organize everything ourselves, so we need reliable partners to take over some of the work. And that’s exactly what Panasonic does for Autorette.”

Resilience helps company bounce back

Cars come and go at Autorette Carwash Systems, which has several wash boxes next to its Helmond premises. Inside, the next installation is ready for delivery to a customer in Germany. Meanwhile, sales via their webshop for car wash accessories are going smoothly. It’s a stark contrast to early 2020 when a major fire broke out. Much was lost, and little was saved. Yet, within a week, Autorette was up and running again, initially from a temporary location, before returning to Helmond.

Business is now busier than ever, says Gerrit Kalshoven, responsible for sales. Despite the full order book, the workload is manageable, thanks in part to a flexible workforce. The operations are well-organized for the increased demand. “We’ve considered expanding our offerings, but that would impact every process. So, we stick to our current technology. It’s specific enough and sets us apart.”