Polymer Capacitors – a superior alternative for MLCCs in every regard?

It is not only since the widespread introduction of 5G...

...that the demand for Multilayer Ceramic Chip Capacitors (MLCCs) is growing: Applications in the field of consumer electronics, data processing, telecommunications and many others have not only significantly intensified MLCC market growth – they even led to an industry-wide shortage for the recent years.

All those parameters contributed to more and more OEMs started looking for alternatives to eventually replace MLCCs with different capacitors – also in anticipation of an increasing demand due to 5G.

Some relevant MLCC alternative can be found within Panasonic Industry’s portfolio: As leading manufacturer of Polymer Capacitors with a long design-in expertise, the SP-Caps and OS-CON are as well worth a closer look as POS-CAP Tantalum Polymer Capacitors or the manufacturer’s Polymer Hybrid Aluminum Electrolytic Capacitor technologies.

For conductive Polymer capacitors, the fields of application have remarkably broadened. The Polymer capacitor (as well as conventional aluminum electrolytic capacitors) stands out with large capacitance figures and excellent bias characteristics that are clearly outperforming multilayer ceramic capacitors.

Panasonic Industry Polymer capacitors already have been proven as a highly relevant alternative for customers seeking to save PCB space and money.

Those Polymer-based capacitors offer a performance edge over conventional electrolytic and ceramic capacitors when it comes to:

• Electrical characteristics

• Stability

• Longevity

• Reliability

• Safety

• Life cycle cost

The various Polymer and hybrid capacitors have very specific advantages and benefits in terms of their ideal voltages, Low ESR, operational conditions and other application requirements.

Polymer capacitors - and what Panasonic Industry has to offer

Including the hybrid ones, there are basically four main varieties of Polymer capacitors. Each of them comprises different construction, electrolytic and electrode materials, packag¬ing and application targets. Let us have a brief overview:

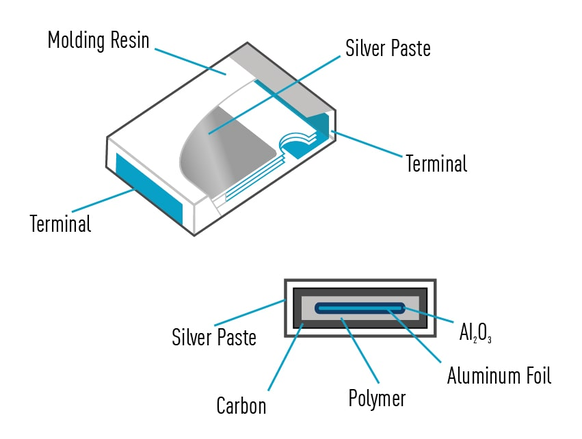

SP-CAPs – the new flagship of Ultra-low ESR

Using a conductive Polymer as the electrolyte and an aluminum cathode, the distinguishing electrical characteristic of these Polymer capacitors is their extremely low equivalent series resis¬tance (down to 3mΩ), which is among the lowest in the industry. SP-caps cover a voltage range from 2–6.3V and offer capacitances between 2.2–820μF. Packaged in a molded resin as compact SMD, these layered Polymer capacitors come in a low pro¬file. As a result of the electrical and form factor characteristics, they suit a variety of handheld electronic devices or other applications that require a low-profile capacitor that will not interfere with a nearby heat sink.

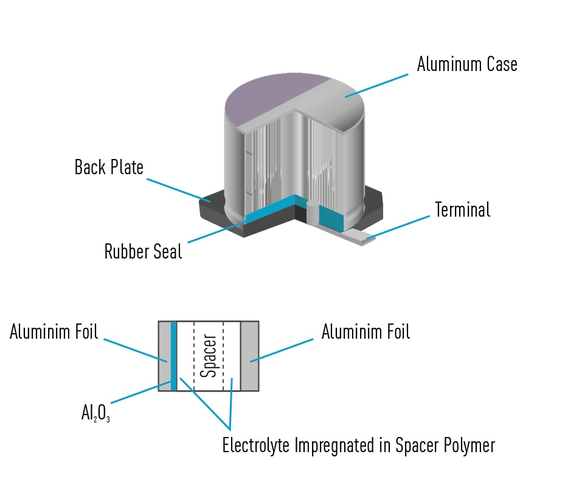

Large capacitance – long lifetime: OS-CON

OS-CON caps are also based on conductive Polymers and aluminum, but they have a wound foil structure. The wound Polymer capacitors cover a wider range of voltages and capacitance values than other types of Polymer capacitors. Voltages extend from 2.5 to 100V, while capacitances run from 3.3 to 2,700μF. In addition, their long life time span is one of the factors that they are preferred to be used for servers and base stations. For example, SVPT series with 20,000 hours of life time at 105°C is a unique solution for such applications.

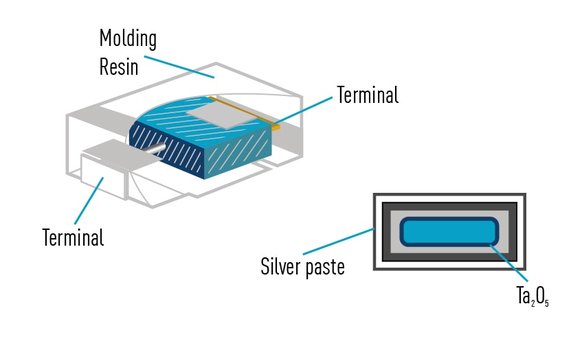

POSCAPs - the chip capacitors of choice for compact devices

These types employ a conductive Polymer as the electrolyte and have a tantalum cathode. They span voltages from 2 to 35V and capacitances from 3.9 to 1,500μF. They also convince with a low ESR, with some of our POSCAP capacitors exhibiting ESR values as low as 5mΩ. Packaged in a molded resin case, the tantalum Polymer capacitors are among the most compact options available on the market. Though compact, a wide range of sizes is available for this capacitor type.

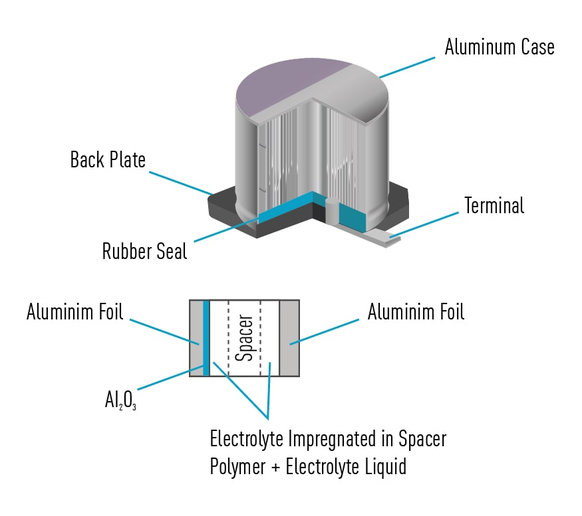

Best of both worlds: Hybrid capacitors

Hybrid capacitors consist of a combination of a liquid and conductive Polymer to serve as the electrolyte and aluminum as the cathode. The Polymer offers high conductivity – and a correspond¬ingly low ESR. The liquid portion of the electrolyte, meanwhile, can withstand high voltages and provide higher capacitance rat¬ings due to its large effective surface area. The hybrid capacitors offer a voltage range from 25 to 80V and capacitances between 10 and 1000μF. At 8 to 120mΩ, ESR values for hybrids are higher than other types of Polymer capacitors, but still very low considering the higher power applications they address.

Polymer capacitors - and what makes them outperform MLCCs and other technologies

It's not only the industry-wide MLCC shortage: Panasonic Industry Polymer caps stand out with excellent specs and characteristics that makes them outperform conventional MLCCs ion several regards.

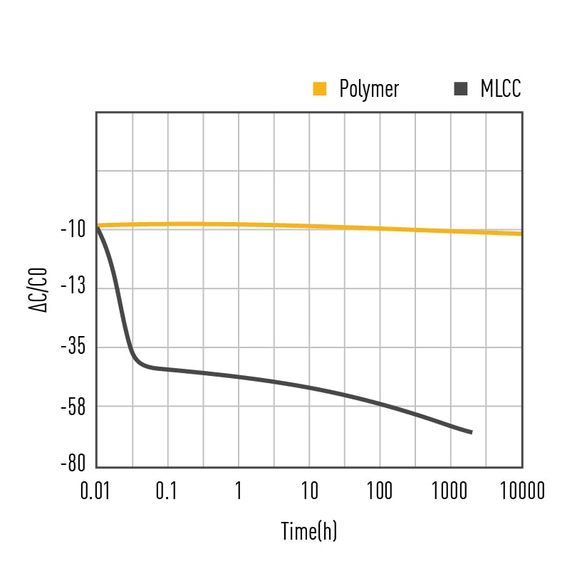

Capacitance density and stability vs. DC bias

The MLCC exhibits strong capacitance dependence on DC bias due to ferroelectric dielectric materials used for MLCCs. Polymer ca¬pacitors have no such problem and remain stable over time. This specific advantage allows a significantly lower part count using Polymer instead of MLCCs – apparently saving precious PCB space, costs and steps during production process.

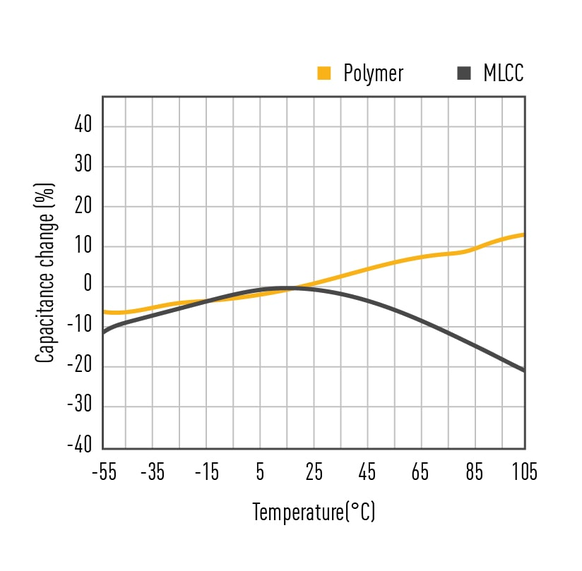

Stability vs. temperature

This figure illustrates typical temperature characteristics. The curve changes for MLCCs in various ways within the tolerance range of each product. For Polymer capacitors the capacitance is growing in parallel to the increase of temperature. The temperature characteristics of MLCCs differ according to the dielectric type, but all of them suffer aging failure by exhibiting temperature dependency and require lower operating temperature. Ceramic capacitors are brittle and sensitive to thermal shock, so precautions need to be taken to avoid cracking during mounting, especially for high-capacitance large MLCCs. Typically, ceramic capacitors reveal a temperature range from -40°C to 85°C, respectively 125°C, while the capacitance varies about from +5% to -40%, being in the optimal range around a low temperature of 5 to 25°C. Also in terms of density, field stress and temperature – which is currently still limited to 125°C – Polymer capacitors have great development potential to achieve higher ratings on density, field stress and temperature (yet currently limited to 125°C) due to their working mechanism and dielectric materials advancement, yet higher dielectric constant Polymers enable a higher energy density.

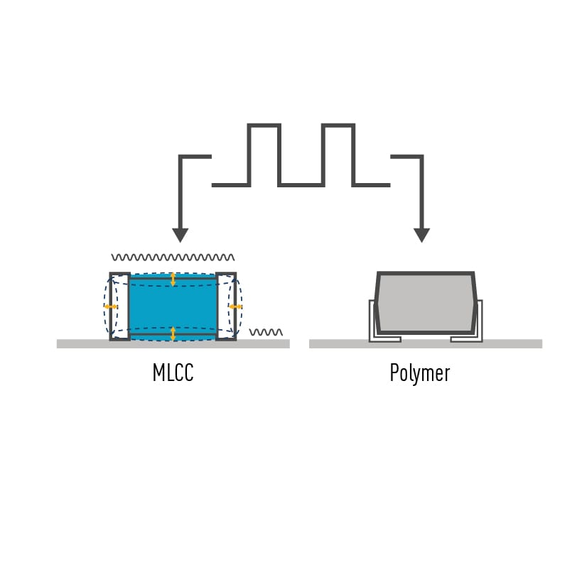

Piezoelectric effects

A MLCC deforms – meaning contraction or expansion - when exposed to voltage. This MLCC's characteristic is called inverse piezoelectric effect - the reverse of a piezoelectric effect. A DC voltage output from an AC adaptor or switching power supply causes a ripple voltage in some cases. If the frequency of the ripple voltage is within the audible frequency range, it may result in emission of a screeching noise. A conductive Polymer capacitor has no inverse piezoelectric effect and therefore does not cause any noise emission or micro-vibrations.

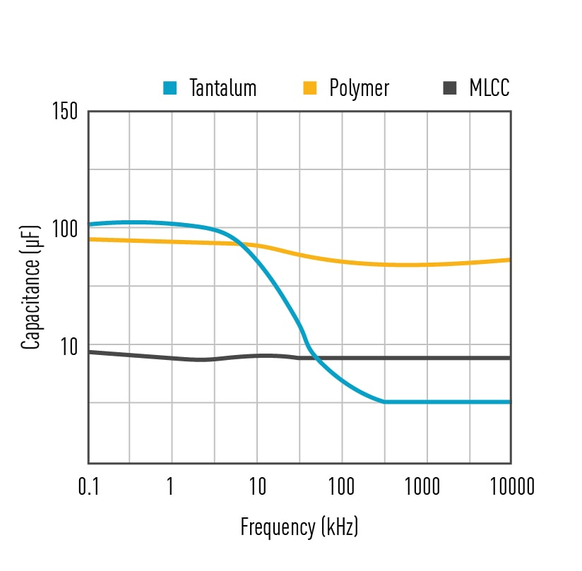

Stability vs. frequency

Stable Capacitance: The figure on the left shows the change in capacitance over a wide frequency range for different technologies. It clearly shows that Polymer capacitors exhibit very similar performance to multi-layer ceramic capacitors.

Robustness

Cracks in ceramic surface mount technology (SMT) components limit assembly reliability and yields. These cracks manifest themselves as electrical defects: intermittent contact, variable resistance, loss of capacitance and excessive leakage currents. That is why MLCCs are exposed to different reliability tests including thermal shock, board flex (bending), and biased humidity tests, etc., depending on the targeted applications. Among the reliability tests, the board flex test evaluates the mechanical resistance to cracking when MLCCs are subjected to bending stress on the printed circuit board (PCB) that the MLCC is soldered on. The bending of PCB can occur frequently during/between manufacturing steps and during operation under temperature variations. Flex cracking is due to excessive circuit board flexure. Ceramics are strong in compression but weak in tension. Thus, when a soldered MLCC experiences excessive board flex, a crack is easily generated in the element. A flex crack can cause an electrical conduction between opposing internal electrodes. It is also possible that a fail open can progress to a fail short with continued product usage. If a crack on a capacitor element progresses to a short circuit failure, it may cause problems such as heat generation, smoking, or ignition; therefore, it is indispensable to take measures against them, particularly in equipment where reliability is essential.

Safety

Most ceramic capacitors have a fairly high voltage rating. If the capacitor experiences a voltage between its terminals higher than its rated voltage, the dielectric may break down and electrons will flow between the thin metal layers inside of the capacitor, creating a short. Luckily, most ceramic capacitors are built with a hefty safety margin and do not experience any sort of catastrophic failure (such as exploding). However, the rule of thumb dictates that you should derate ceramic capacitors by 50% to 90% depending upon series, voltage and temperature, which means that if you are expecting to have a maximum of 5V between the capacitor’s leads, then you should use a capacitor rated for 10V or more. On the other hand, no derating needs to be considered for Polymer capacitors and normally they can withstand 15-25% surge voltage as well.

Conclusion

The range of Polymer caps as MLCC alternatives is various and comprehensive – there are specific types for specific requirements. What they all have in common, however, is that they are a contemporary choice in terms of electrical performance, reliability, durability and safety - and not least when looking at the overall lifetime cost.

Or to put it even more simply: Polymer caps are not only a good alternative in case of supply shortages of other products, but are actually the first choice for the design process of modern applications.