Transparent conductive film - FineX (Fine Cross)

Panasonic’s Transparent Conductive Film FineX (Fine Cross) is …

The metal mesh type transparent conductive film, which achieves both high transmissivity and low resistance, was developed using Panasonic's proprietary method.

Since it can conduct electricity in transparent areas where visible light transmission is required, the following can be achieved:

-

Generation of capacitance

-

Current flow to the device

-

Generation of heat

Fundamental specifications

| Item | Fundamental Specifications |

| Wiring Line Width | 2 um or more |

| Transmissivity | 89 % *1 |

| Aperture ratio | 96 % |

| Base material | PET / PC |

| Bendability | R2 mm or more *2 |

*1: Including film base material. *2: Film only.

Development background / Transparent conductive film is …

What is a Transparent conductive film?

Transparent conductive films have the function of transmitting both electricity and visible light. ITO (Indium Tin Oxide) has been widely used as a transparent electrode for various applications, such as touch displays or solar battery cells.

From ITO (Indium Tin Oxide) to Metal Mesh

ITO (Indium Tin Oxide) typically has a resistance of tens to hundreds of ohms per square. ITO must be applied in thicker layers to meet the increasing demand for lower resistance in recent years. However, this thickness can reduce transmissivity and color changes, such as yellowing. To address these challenges, there is a push for developing and using alternative materials to ITO. One such alternative is the metal mesh, which Panasonic has developed.

Metal Mesh: Conventional etching method

Etching methods are generally used to produce metal meshes, but it is difficult to achieve both low resistance and fine wiring. When large size is required, transmissivity is sacrificed by the increased line width in order to lower the resistance.

In addition, metal remainder at the cross point, which tends to happen in the metal mesh produced by etching process, causes deterioration of appearance.

Panasonic’s proprietary roll-to-roll process

Panasonic has developed the industry’s first* roll-to-roll process to create the double-sided wiring Transparent Conductive Film FineX (Fine Cross). By using our proprietary method, we achieve a high wiring aspect ratio and produce the Transparent Conductive Film FineX (Fine Cross), which balances high transmissivity and low resistance.

Items |

FineX

|

Conventional Etching Method

|

| Visibility - Wiring Line Width | 4 um | ≦2 um |

| Transmissivity | 90.3% | 94.1% |

| Aperture ratio | 96 % | 92% |

| Sheet Resistance | 2 ohms/sq. | 2 ohms/sq. |

| Frame Wiring (L/S) | 15/15 um | 8/8 um |

| Base material | PET and COP | PET, PC and COP |

| Bendability | ≧ R2 mm | ≧ R2 mm |

Comparison with our prototypes: *1: Including film base material *2: Film only

Fine wiring

Panasonic's proprietary process has enabled fine wiring widths of 2um or more.

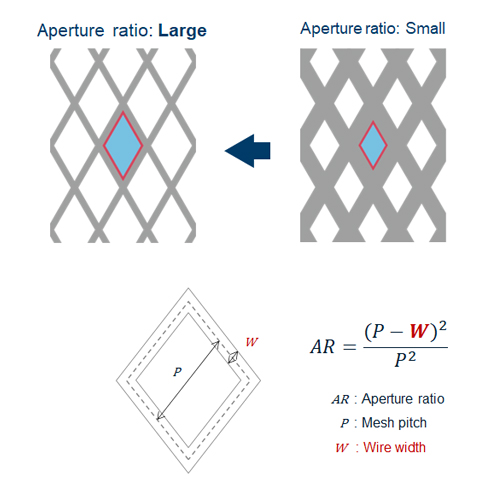

High aperture ratio

Wire thinning significantly enhances the aperture ratio.

Because metal obstructs light, reducing the width of the metal wiring leads to an increased aperture ratio. The aperture ratio is directly proportional to transmissivity. As a result, Panasonic's Transparent Conductive Film, FineX (Fine Cross), can achieve high levels of transmissivity.

| AR = (P - W)2 / p2 |

AR: Aperture ratio |

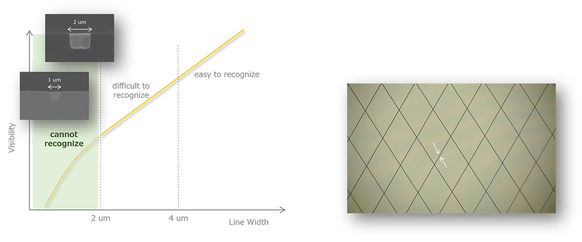

Visibility of wiring lines

Metal wiring lines can be visible due to light reflecting off the metal, especially if the lines are not thin enough.

However, in Panasonic’s Transparent Conductive Film FineX (Fine Cross), the wiring line width is 2 micrometers or more, rendering the mesh pattern invisible to the human eye.

Wiring with high aspect ratio

The resistance value of a wire is inversely proportional to its cross-sectional area. To maintain a low resistance, it is necessary to increase the cross-sectional area.

Panasonic’s Transparent Conductive Film, FineX (Fine Cross), is produced using a proprietary process that features wiring lines with a high aspect ratio. This design increases the cross-sectional area in the depth direction while keeping the line width fine.

As a result, FineX achieves fine wiring, which promotes high transmissivity and low resistance.

| R = ρ * (L / A) | R: Resistance ρ: Resistivity L: Wire length A: Wire cross-sectional area |