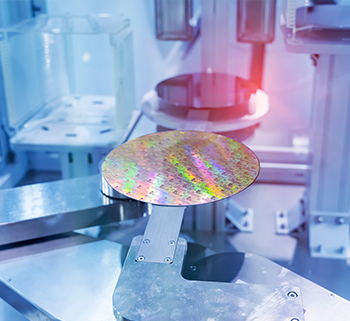

Sensor technology for the semiconductor industry

Optimise the front-end process with our customised sensors

The conditions during front-end processes for chip production are specific. Think of extremely high temperatures, of chemical liquids and vacuum environments. Get to know the unique features of our sensors for the Semicon Industry. They go beyond the applications of standard sensors, are compact and robust and offer their value especially under more demanding conditions.

Sensors for wafer mapping

Wafers are getting thinner and closer together in a FOUP. This increases the pressure on accurate detection of any errors. How many wafers are stacked in a FOUP? And just as important: are they positioned correctly? Thanks to a very compact sensor technology, our custom-made products provide the necessary certainty. We can also equip our sensors with unique lenses. As a result, during wafer detection, the sensor receives no annoying reflection from top or underlying wafers, preventing a crash by the handling robot.

Sensors for wafer detection

The handling robot must pick up a wafer properly every time. So our tailor made solutions include sensors for wafer detection. A specific housing makes them suitable for application at high temperatures, allowing the customer to pick up the wafers earlier. Our sensors are suitable for a wide variety of wafers, including glass variants. Moreover, with their very thin housing, they can be designed in the thinnest end-effector.

Sensors for wafer transfers

For semiconductors, the interface of wafer transfers is situated at the load port. So it is precisely there that operator safety is important, to which our sensors contribute. They ensure accurate positioning of a product, making sure the robot arm is reaching to exactly the right length - and not a millimetre further. Our sensors have safety levels PLc or PLd, depending on the application required.

The market demands chips that perform better and better. Which increases the complexity of those same chips, for applications that until recently seemed so far away. To keep meeting those expectations: how do you ensure this as a chip machine manufacturer? How do you maintain the required precision, without any concessions on efficiency?

The answer lies in the latest automation. In customisation, such as with our sensor technology for the front-end production of chips. So not standard products, but applications to improve wafer handling and detection. And thus increase security, increase output and optimise the yield of expensive and vulnerable base material.

Strengthen the front-end process for chip production and exploit the specific capabilities of our sensor technology. From our local offices throughout Europe we are literally close by, supported by an internationally operating parent company. Discover the unique features of our sensors below, and contact us for more information. We will gladly explain the possibilities to you.